Pulverized coal fineness online measuring device and method based on charge induction

A technology of pulverized coal fineness and charge induction, which is applied in the direction of measuring devices, particle size analysis, particle and sedimentation analysis, etc., can solve the problems of not being able to meet the real-time adjustment of boilers, long and short measurement periods of pulverized coal fineness, and achieve Short measurement period, low maintenance cost, satisfying the effect of real-time adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

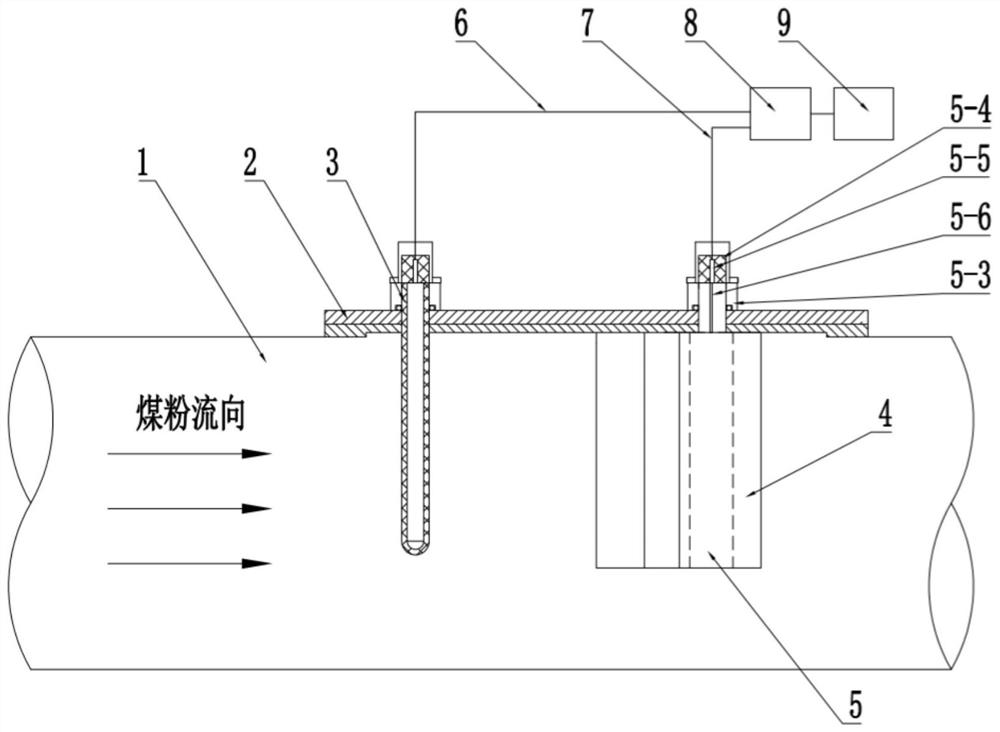

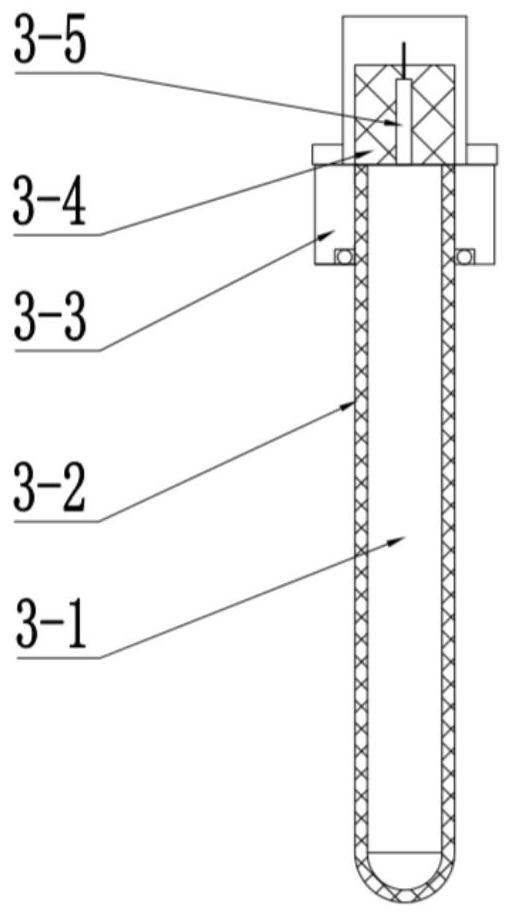

[0030] An on-line measurement device for coal powder fineness based on charge induction, including a flange 2, a first induction electrode 3, a second induction electrode 5, an elbow diversion groove 4, a signal conditioning unit 8 and a signal acquisition and calculation unit 9. The first sensing electrode 3 and the second sensing electrode 5 are respectively connected to the signal conditioning unit 8 through the first shielded signal cable 6 and the second shielding signal cable 7, and the signal conditioning unit 8 is used to control the first sensing electrode 3 and the second sensing electrode The electric signal of 5 is amplified, filtered and signal converted, and the output terminal of the signal conditioning unit 8 is connected with the signal acquisition and operation unit 9 .

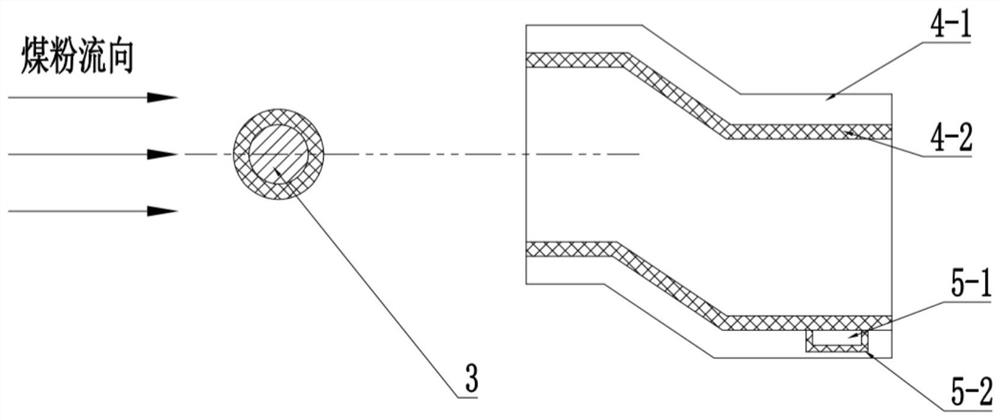

[0031] Such as figure 1As shown, the flange 2 is fixedly installed on an outer side wall of the pulverized coal pipeline 1 , and the elbow guide groove 4 is installed on an inner side wall o...

Embodiment 2

[0044] The working principle of pulverized coal flowing through the online measuring device of this scheme is as follows:

[0045] The airflow with coal powder flows through the first induction electrode 3 and then flows through the diversion groove 4 of the elbow. When the pulverizing system is in normal operation, the flow velocity of the pulverized coal airflow is generally 15-32 m / s. The pulverized coal airflow belongs to the gas-solid two-phase flow, and it is a dilute phase flow. The pulverized coal is crushed and the pulverized coal particles in the process of pneumatic transmission Charges will be generated on the surface, and when the pulverized coal particles flow around the first sensing electrode 3 and the second sensing electrode 5, induced charges will be formed on the corresponding metal electrodes, and these induced charges will pass through the first shielded signal cable 6, the second shielded signal cable The cable 7 is led into the signal conditioning unit ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bend angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com