Mounting head assembly for stably clamping lens

A technology for installing head and stabilizing equipment, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., and can solve problems such as damage, difficult air discharge of cushion pads and limit grooves, and impact on accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention provides a mounting head assembly for stably clamping lenses, which is suitable for the field of lens processing. The present invention can be implemented in the following ways:

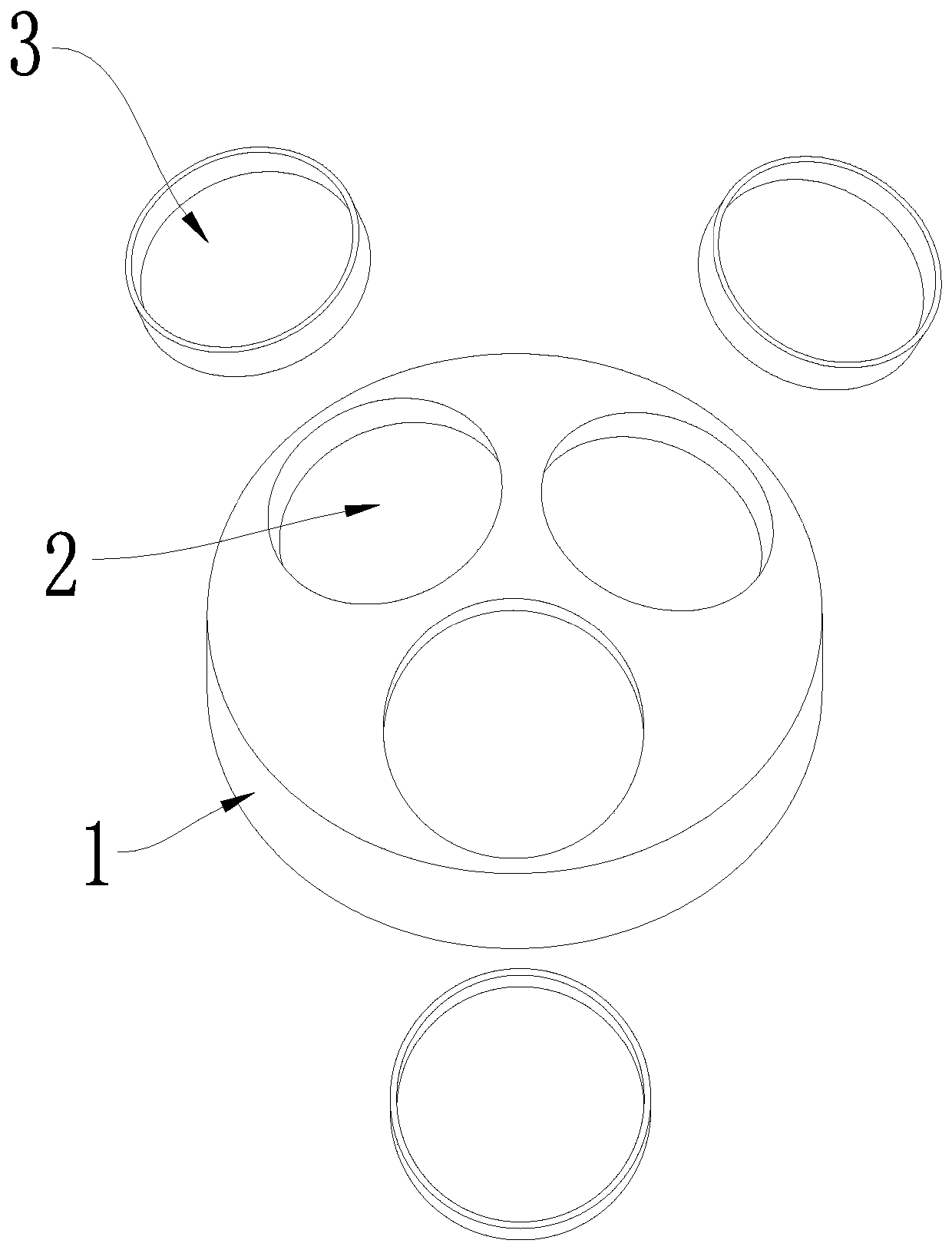

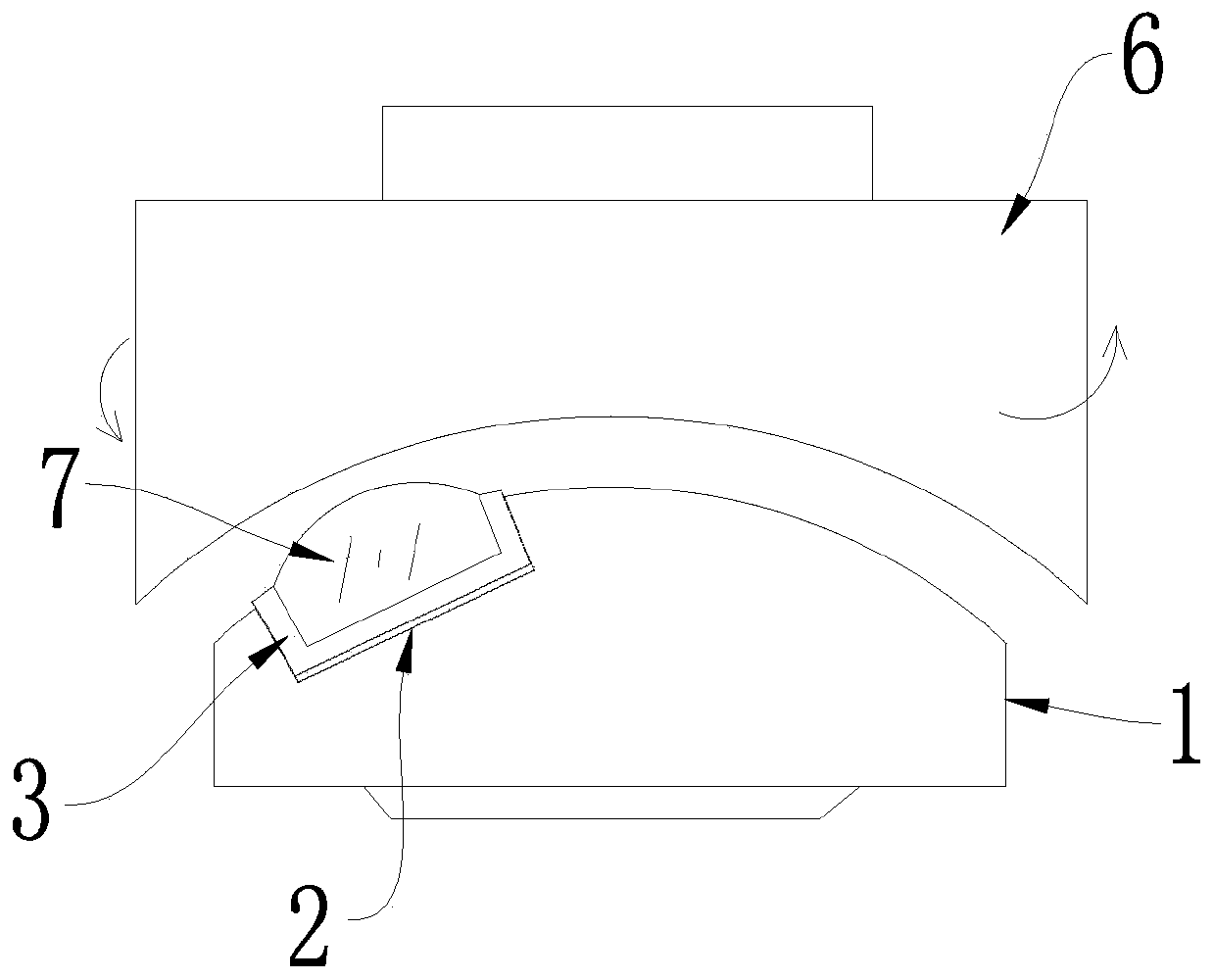

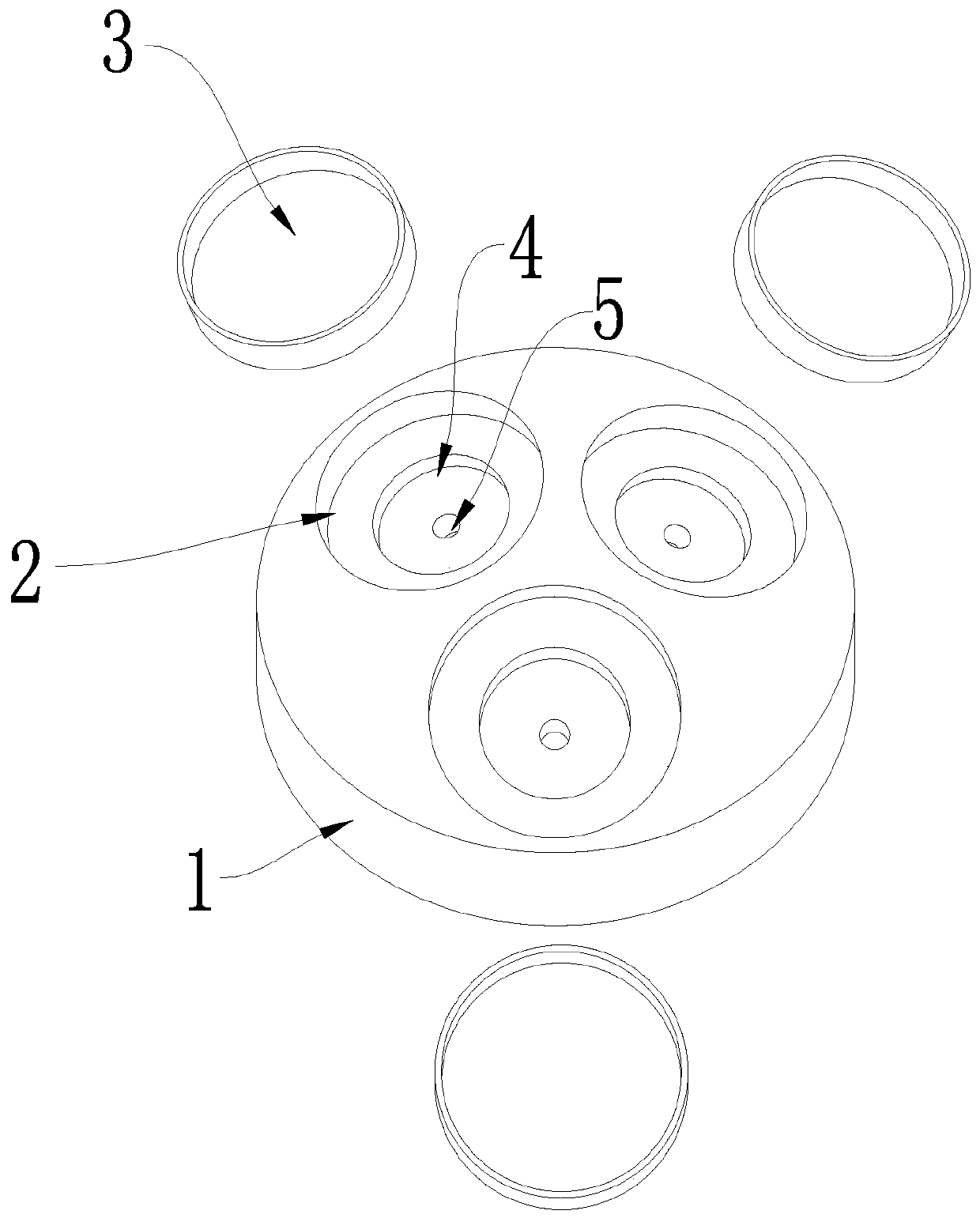

[0015] Such as Figure 3-5 Shown: a mounting head assembly for stably clamping the lens, including a convex spherical mounting head 1, a buffer pad 3 for pressing the lens 7, the groove of the buffer pad 3 is designed based on the shape of the lens 7, which can make the lens It fits seamlessly in the groove of the buffer pad 3. On the grinding surface of the installation head 1, there is a limiting groove 2 for pressing the buffer pad 3. The buffer pad 3 can fit tightly in the limiting groove 2. The bottom surface of the limit groove 2 is provided with an inner groove 4 with a diameter smaller than the limit groove 2. In order to make the bottom surface of the limit groove 2 contact with the buffer pad 3, the buffer pad 3 can be effectively supported to ensure that the grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com