Diamond bead automatic edge cutting machine

A diamond beading and beading technology, which is applied in the direction of metal processing equipment, grinding machine parts, other manufacturing equipment/tools, etc., can solve the problem that the cutting effect cannot be guaranteed, the roundness of the carcass cannot be guaranteed, and the depth of the cutting edge is inconsistent, etc. Problems, to achieve the effect of convenient control of exposure height, reduction of early drop of diamonds, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

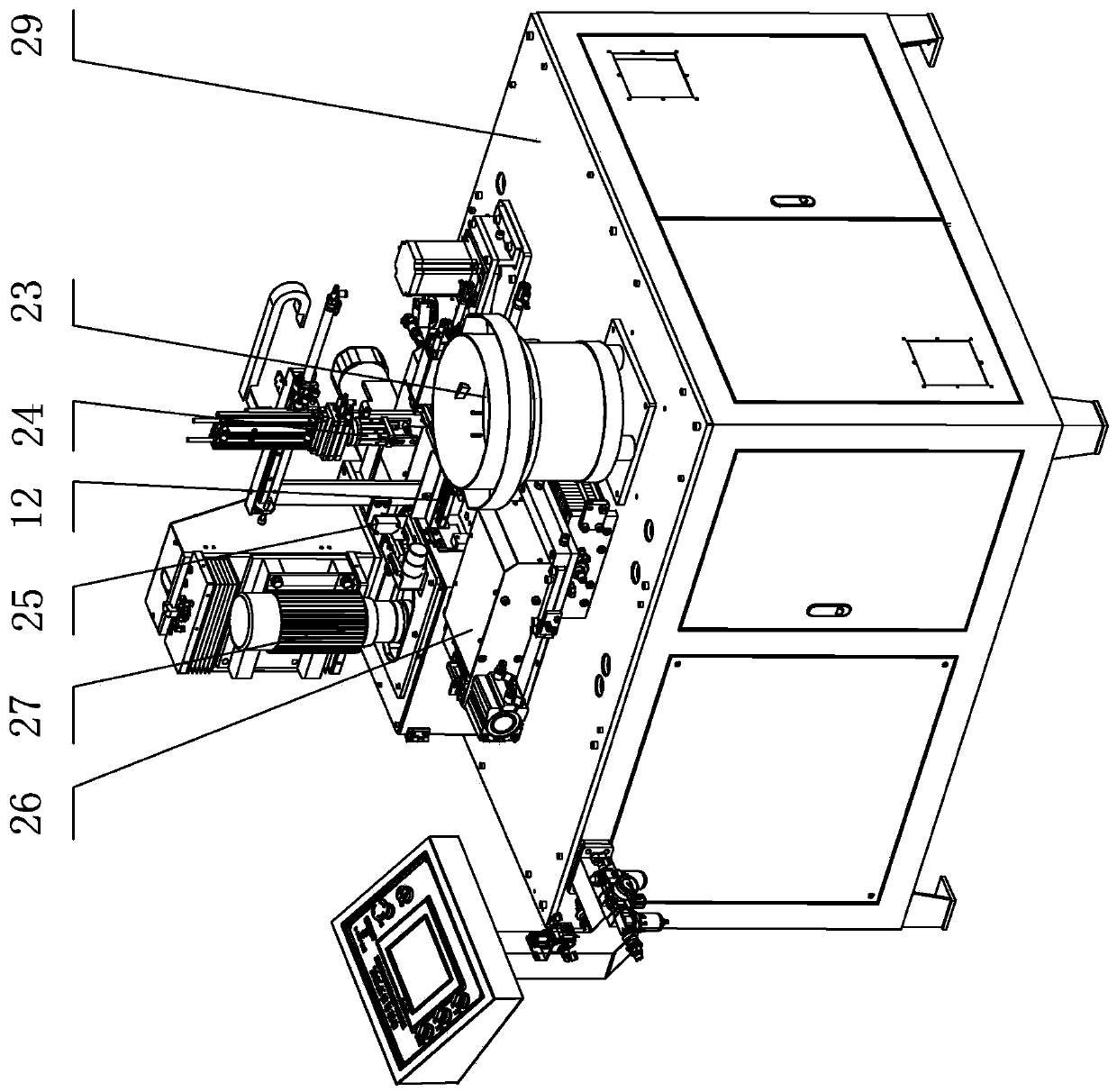

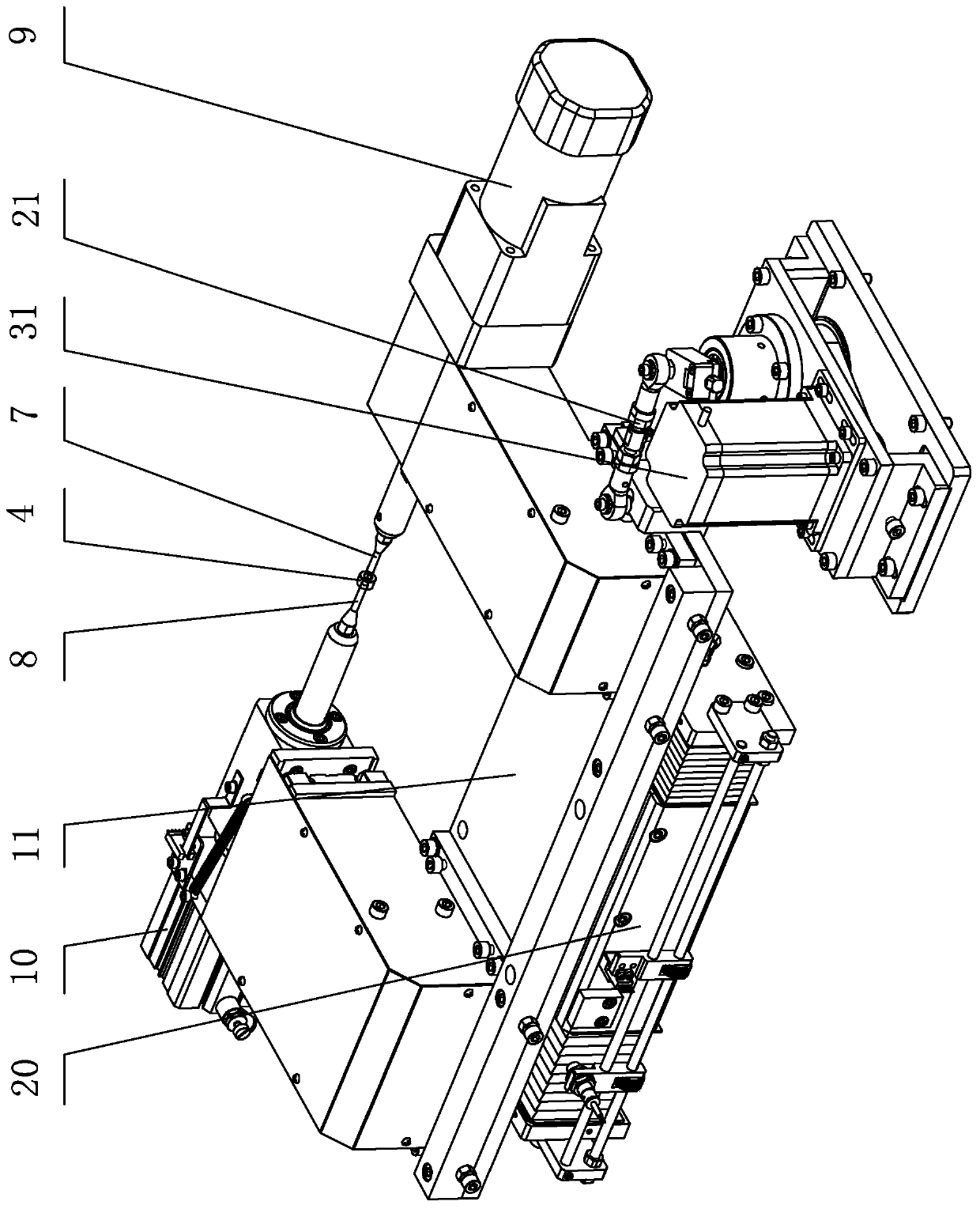

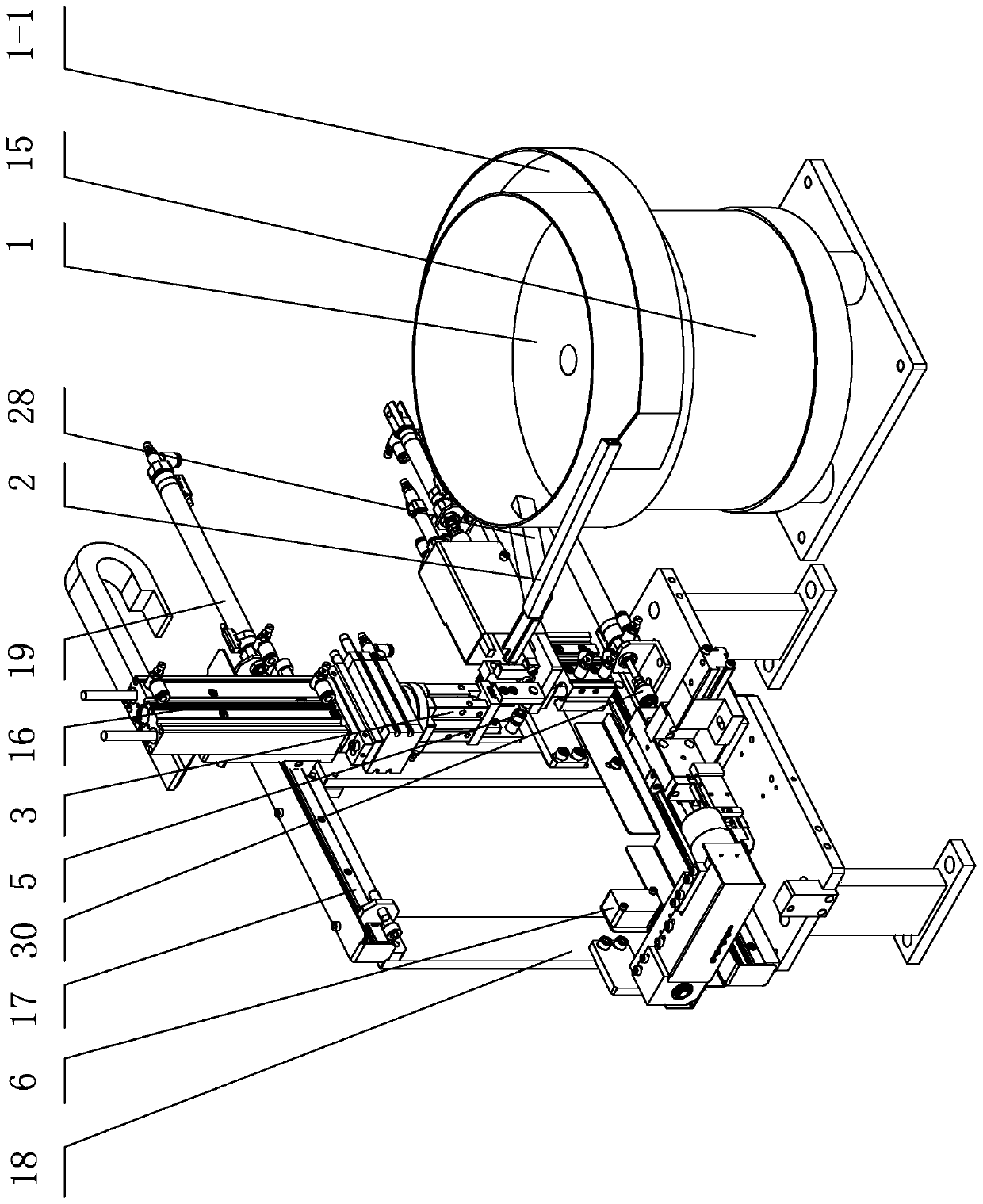

[0026] The diamond beading automatic sharpening machine of the present invention comprises a beading vibrating feeding device 23, a beading reversing device 24, a beading direction detection device 25, a beading clamping rotary swinging device 26 and a grinding wheel swinging feeding device 27, which are set based on a machine platform 29, The bead vibration feeding device 23 is arranged at the right rear, the bead reversing device 24 is arranged at the front, and the bead clamping and rotating swing device 26 is arranged on the left side of the bead vibrating feeding device 23 and the bead reversing device 24 , the grinding wheel swing feeding device 27 is arranged on the left side of the beading clamping and rotating swinging device 26, and the beading direction detection device 25 is arranged between the grinding wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com