Method and device for grinding and polishing parts and molds by mixing laser

A component and laser technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of dimensional deviation, inability to grind and polish fine texture or deep groove feature workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

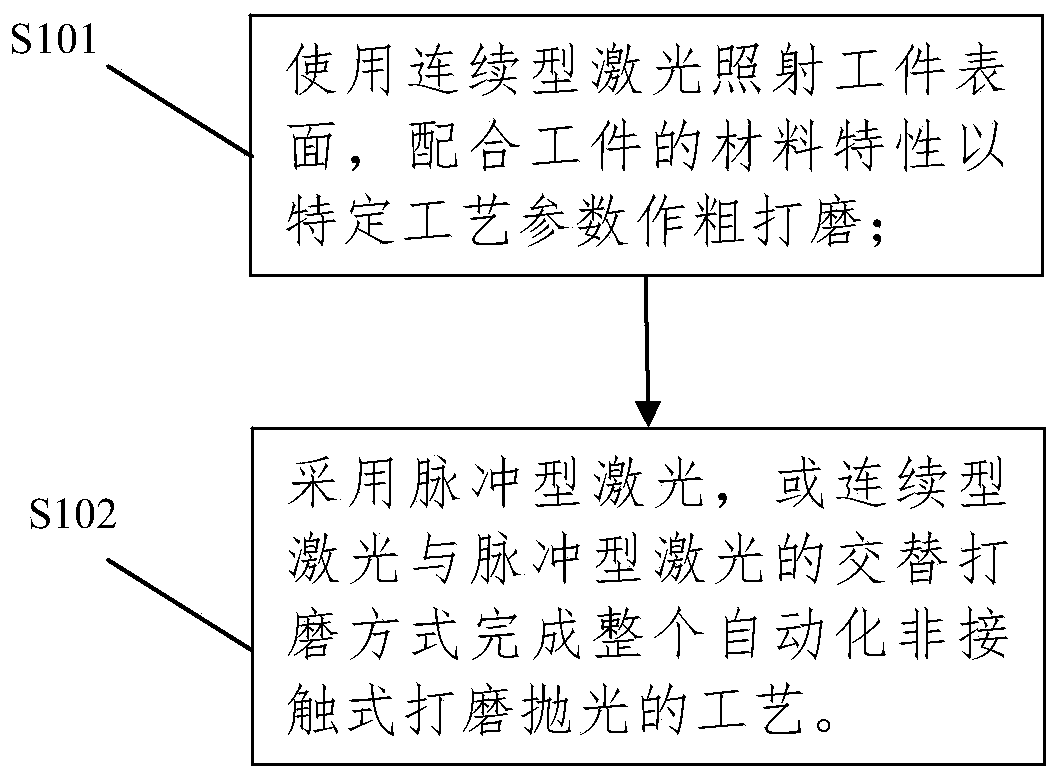

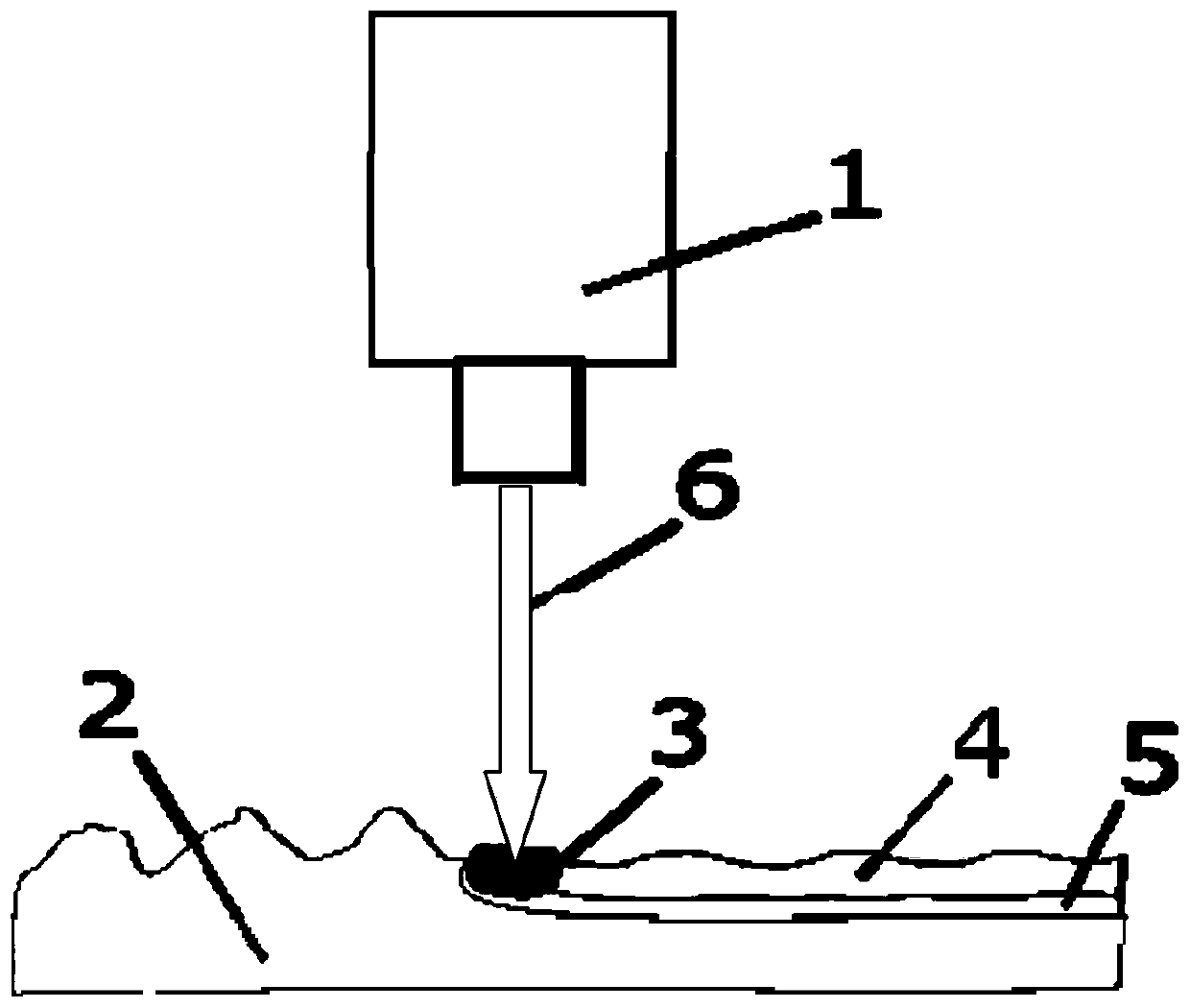

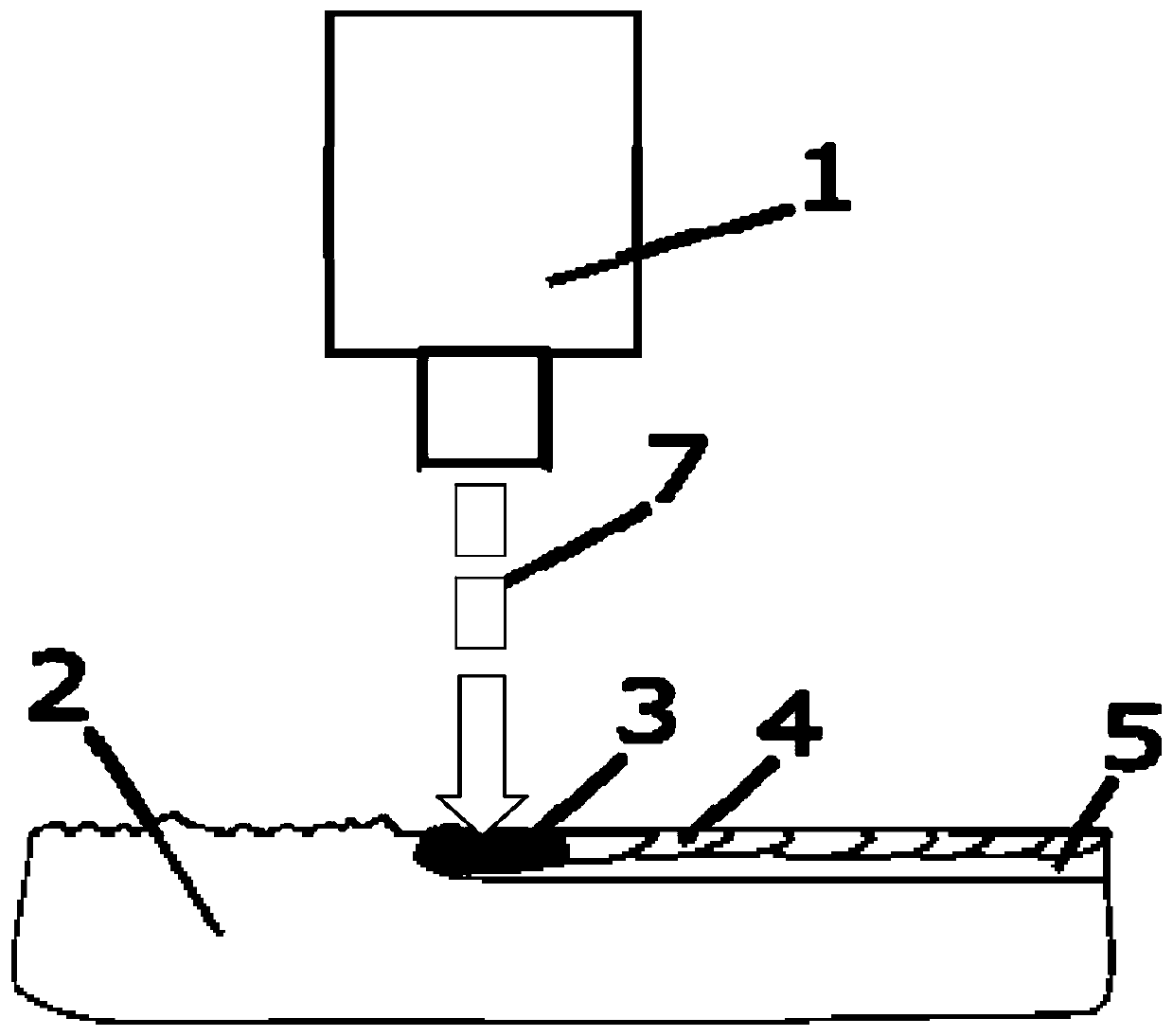

[0017] Please refer to figure 1 , the present invention provides a method for hybrid laser grinding and polishing parts and molds, which is characterized in that it includes: step S101, using a continuous laser to irradiate the surface of the workpiece, and performing rough grinding with specific process parameters in accordance with the material characteristics of the workpiece; step S102, The entire automatic non-contact grinding and polishing process is completed by using a pulsed laser, or an alternate grinding method of a continuous laser and a pulsed laser.

[0018] In one embodiment, the irradiating the surface of the workpiece with a continuous laser, and performing rough ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com