Movable waste fungus bag crushing separator and working method

A mobile and separator technology, applied in grain processing and other directions, can solve the problem of not being able to move at will, and achieve the effect of promoting development and utilization, purifying air quality, and promoting comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

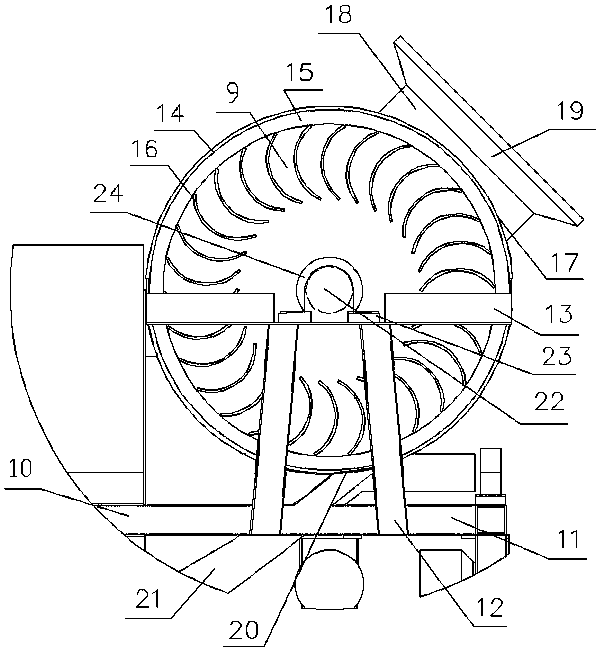

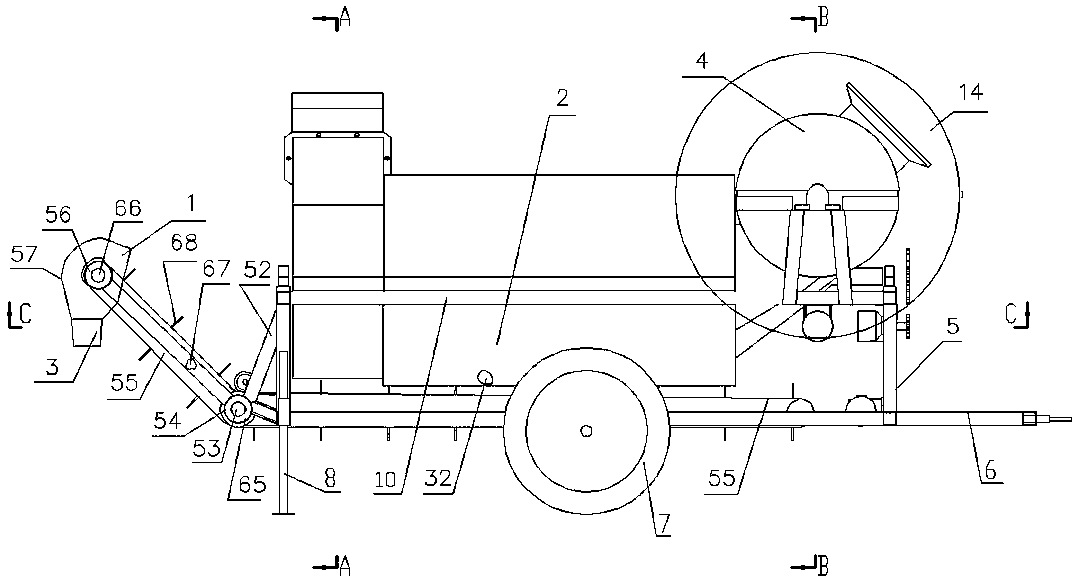

[0031] A mobile waste fungus bag crushing and separating machine, which is composed of: a drag assembly 6, the drag assembly is connected to a frame 5, the frame is connected to a crushing assembly 4, and the crushing assembly includes a bottom Frame 11, the bottom frame is connected to the eight-shaped support frame 12, the eight-shaped support frame is connected to the bracket 13, the bracket clamps the broken and ejected shell 14, and the eight-shaped support frame clamps the The crushing and throwing shell, the crushing and throwing shell has a round shell plate 9, the round shell plate is connected to the crushing and throwing shell 14, and the round shell plate is connected The air duct ring 15 is connected to the air duct 10, the circular shell plate 9 is connected to a set of arc-shaped air plates 16 around the circumference, and the top of the crushing and throwing shell is provided with crushing and throwing materials. Inlet 17, the crushing and throwing material inle...

Embodiment 2

[0033] In the mobile waste fungus bag crushing and separating machine described in embodiment 1, the crushing and throwing shell is connected to the through shaft 22, and the eight-shaped support frame is connected to the front pair support plate 23, and the front pair support plate Connected to the opening support frame 24, the opening support frame is connected to the through shaft, the through shaft is connected to the transmission sprocket 37, the transmission sprocket is connected to the driving sprocket 38 through the chain 39, the driving chain The wheel is connected to the crushing motor 58, and the front pair of support plates and the opening support frame both clamp the crushing and throwing shell.

[0034] The eight-shaped support frame can well support the broken and thrown shell, ensuring that the broken and thrown shell is safe to use and has a good crushing effect.

Embodiment 3

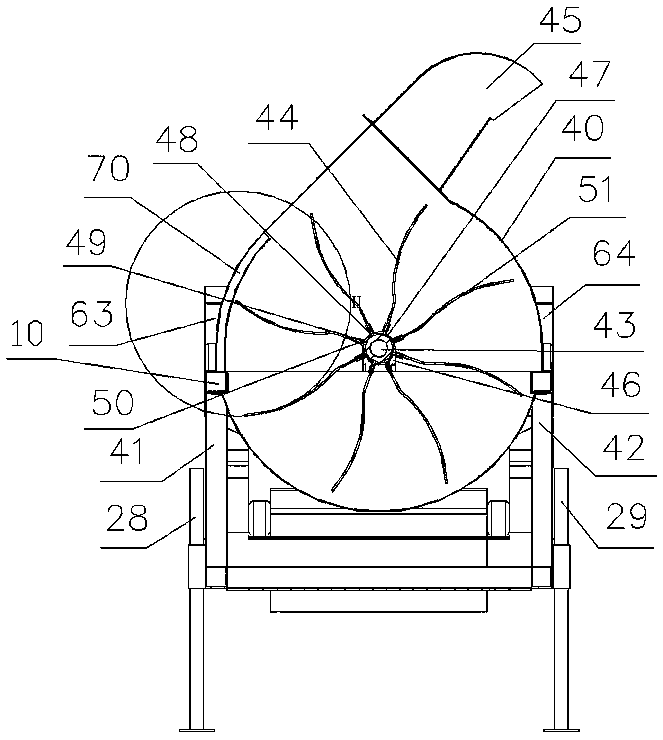

[0036] In the mobile waste fungus bag crushing and separating machine described in embodiment 2, a set of clamping plates 59 and a set of clamping plates 60 are welded around the circumference of the through shaft, and the clamping plate is connected to the The clamping plates are arranged in pairs, the crushing knife 61 is clamped between the clamping plate and the pair of clamping plates and fixed by bolts, and the crushing and throwing shell is connected with a set of horizontally arranged guide plates 杆62.

[0037] The crushing knives are evenly distributed on the through shaft, which can smoothly chop the waste fungus bags. Part of the wind sent from the air duct circle can smoothly enter the chopped waste fungus bags into the crushing and throwing outlet chute, and the crushing and throwing outlet is slippery. Dao can send out the shredded waste fungus bag smoothly, and the use effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com