Calcium oxide production device and production method

A production method and technology of a production device, which are applied in the field of calcium oxide production technology, can solve the problems of limited economic benefit, large investment cost, limited amount of consumption, etc., and achieve the advantages of improving mass transfer and heat transfer efficiency, improving product quality and simple device structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

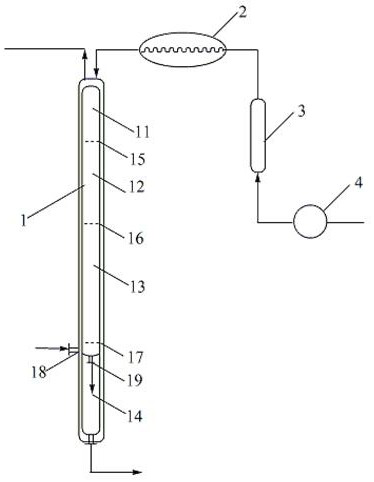

[0024] A calcium oxide production device, comprising a reaction tower 1, a cage-stirring squeeze conveyor 2, an air dryer 3, a raw material delivery pump 4, the reaction tower 1, a cage-stirring squeeze conveyor 2, an air dryer 3, a raw material The transfer pumps 4 are connected sequentially. The reaction tower 1 is sequentially provided with a drying zone 11, a reaction preheating zone 12, a high-temperature roasting reaction zone 13, and a feeding zone 14 from top to bottom. Vibrating sieve 15, the bottom of the reaction preheating zone is provided with a fluidized vibrating sieve 16 in the reaction preheating zone, the bottom of the high temperature calcination reaction zone is provided with a calcination fluidized bed 17, the bottom of the high temperature calci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com