A kind of regeneration method of desulfurization adsorbent

A technology of adsorbent and metal, which is applied in the field of regeneration of desulfurization adsorbent, can solve the problems of inability to restore the adsorbent, increase the cost of regeneration, and inapplicability, and achieve the elimination of by-products, avoiding the reduction of activity, and avoiding the loss of sulfur capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

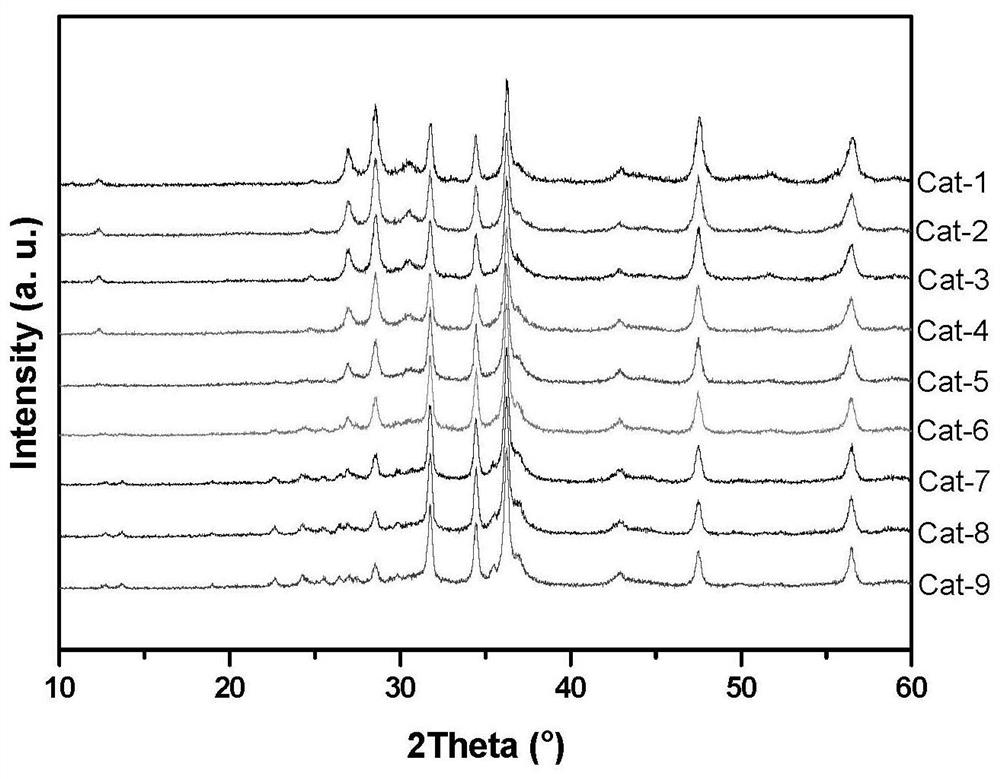

Embodiment 1

[0094] Regeneration of deactivated desulfurization adsorbent:

[0095] Take 5g of inactivated desulfurization adsorbent Cat-1 and put it in a tubular reactor. 2 , the gas pressure is 0.1MPa, the air velocity is 3.6L h -1 g -1 Under the conditions of purging for 12h, then at a temperature of 500 ° C, the gas is 3% O 2 / N 2 Mixed gas, gas pressure 0.1MPa, airflow space velocity 3.6L h -1 g -1 Roasting under the conditions of 12h, get regenerated desulfurization adsorbent, denoted as Cat-2.

Embodiment 2

[0097] Take 5g of inactivated desulfurization adsorbent Cat-1 and put it in a tubular reactor, and regenerate the deactivated adsorbent with the same regeneration method as in Example 1, except that the roasting time is changed from 12h to 24h, to obtain the regenerated desulfurization adsorbent agent, denoted as Cat-3.

Embodiment 3

[0099] Take 5g of inactivated desulfurization adsorbent Cat-1 and put it in a tubular reactor, and use the same regeneration method as in Example 1 except that the roasting time is changed from 12h to 36h to regenerate the deactivated adsorbent to obtain the regenerated desulfurization adsorbent agent, denoted as Cat-4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com