Graphene-based high-performance composite lithium metal negative electrode material and preparation method thereof

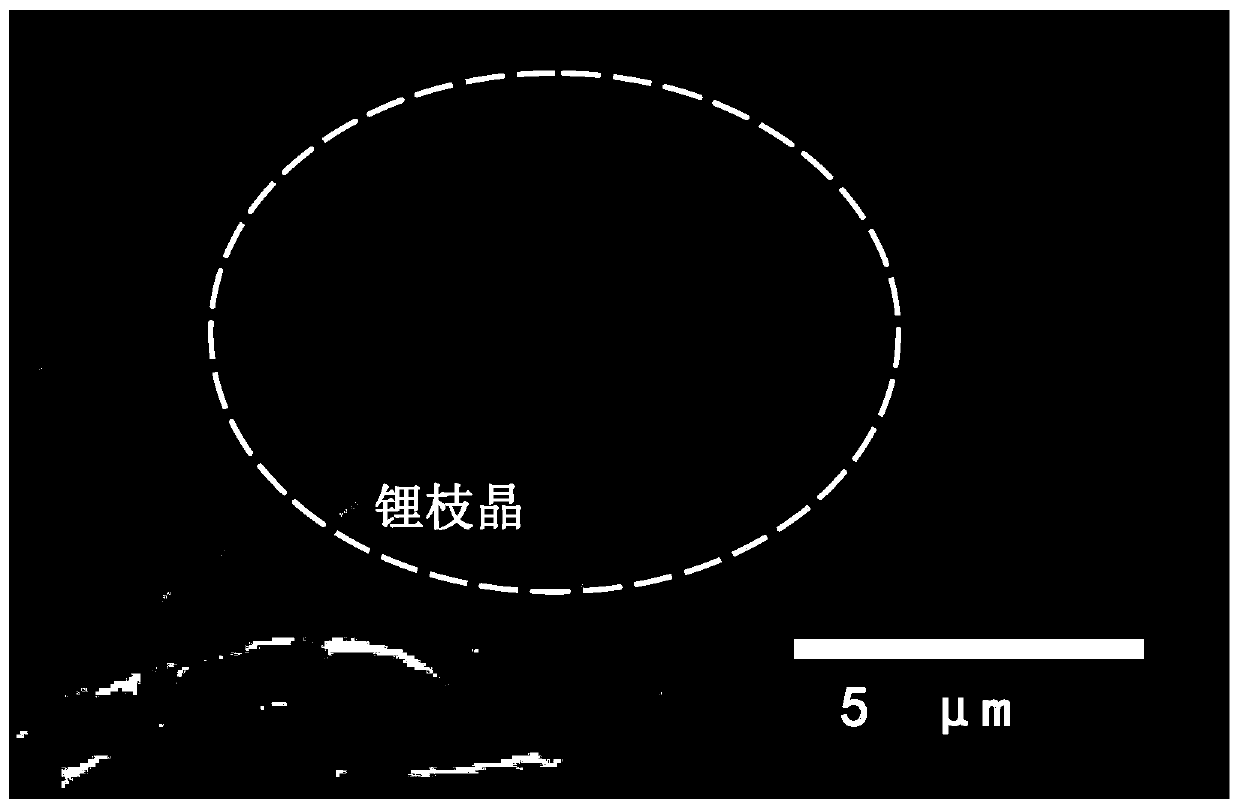

A metal negative electrode, high-performance technology, applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of capacity decay, continuous cycle collapse, SEI can not adapt to volume changes, etc., to inhibit the formation of lithium dendrites, The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

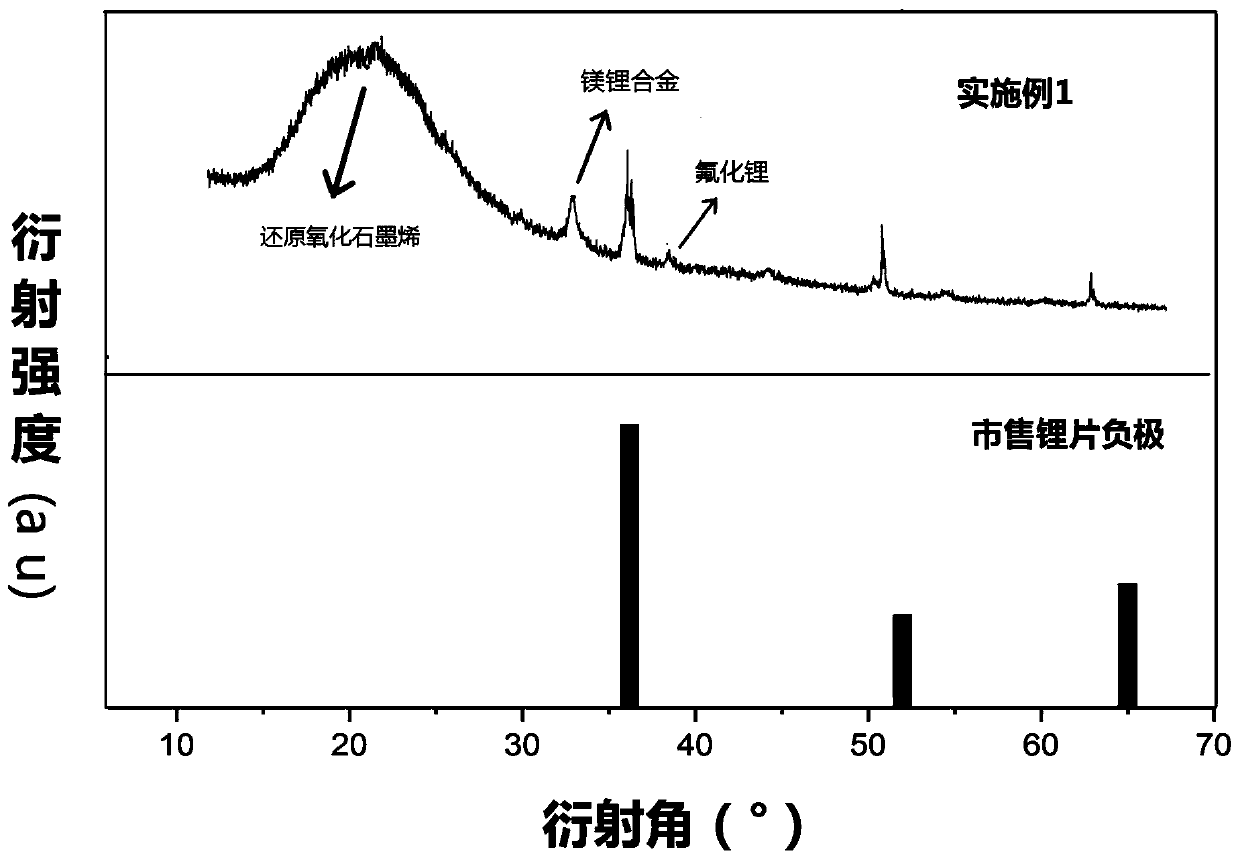

Embodiment 1

[0032] (1) Add 45㎎zinc fluoride and 15㎎magnesium fluoride into 10mL of deionized water and stir evenly, and then disperse with 300w ultrasonic wave at a frequency of 40kHz for 10min.

[0033] (2) Add 20 mL of GO solution with a concentration of 4 mg / mL to the above solution, and stir for 12 h at a speed of 600 r / min to obtain a composite GO solution doped with magnesium fluoride.

[0034] (3) Take 3 ml of composite GO solution, vacuum filter with a water-based filter membrane, the relative vacuum degree is -0.08Mpa to obtain GO hydrogel, and put the GO hydrogel together with the filter membrane into a relative vacuum degree of -0.5Mpa temperature Dry in a vacuum oven at 50 °C for 12 h to obtain a GO film with a thickness of 30 μm.

[0035](4) In a glove box filled with argon protection with water and oxygen content lower than 0.1ppm, 304 stainless steel is used to heat lithium metal to 400°C to change lithium metal from solid to liquid. Then, the edge of the GO film with a di...

Embodiment 2

[0037] (1) Add 40㎎zinc fluoride and 15㎎magnesium fluoride into 10mL of deionized water and stir evenly, and then disperse with 60kHz frequency and 600w ultrasonic wave for 15min.

[0038] (2) Add 20 mL of GO solution with a concentration of 4 mg / mL to the above solution, and stir for 12 h at a speed of 700 r / min to obtain a composite GO solution doped with magnesium fluoride.

[0039] (3) Take 3 ml of composite GO solution, vacuum filter with a water-based filter membrane, the relative vacuum degree is -0.1Mpa to obtain GO hydrogel, put the GO hydrogel together with the filter membrane into the relative vacuum degree of -1Mpa and the temperature is Dry in a vacuum oven at 65 °C for 24 h to obtain a GO film with a thickness of 40 μm.

[0040] (4) In a glove box filled with argon protection with water and oxygen content lower than 0.1ppm, 304 stainless steel is used to heat lithium metal to 450°C to change lithium metal from solid to liquid. Then, the edge of the GO film with a...

Embodiment 3

[0042] (1) Add 42.5㎎zinc fluoride and 15㎎magnesium fluoride into 10mL of deionized water and stir evenly, then disperse for 12.5min with frequency and 50kHz power of 500w ultrasonic waves.

[0043] (2) Add 20 mL of GO solution with a concentration of 4 mg / mL to the above solution, and stir for 15 h at a speed of 650 r / min to obtain a composite GO solution doped with magnesium fluoride.

[0044] (3) Take 3 ml of composite GO solution, vacuum filter with a water-based filter membrane, the relative vacuum degree is -0.09Mpa to obtain GO hydrogel, put the GO hydrogel together with the filter membrane into a relative vacuum degree of -0.75Mpa temperature Dry in a vacuum oven at 55 °C for 15 h to obtain a GO film with a thickness of 35 μm.

[0045] (4) In a glove box filled with argon protection with water and oxygen content lower than 0.1ppm, 304 stainless steel is used to heat lithium metal to 425°C to change lithium metal from solid to liquid. Then, the edge of the GO film with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com