Electrode preparation method and battery

An electrode and electrode film technology, applied in the field of electrode preparation method and battery, can solve the problems of large amount of solvent and long process time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

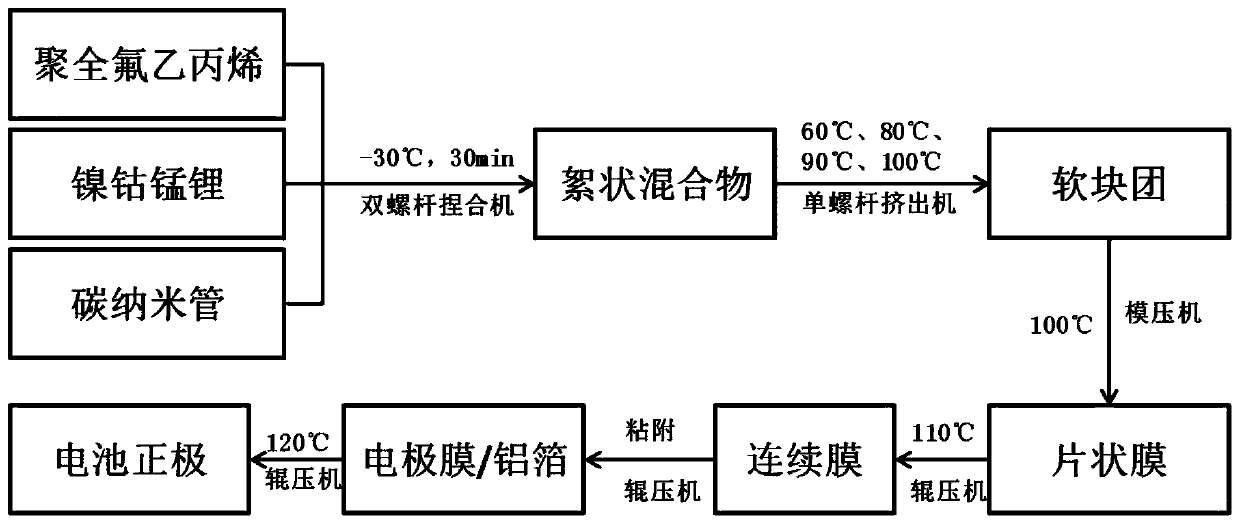

[0031] In this example, the positive electrode active materials nickel-cobalt-manganese-lithium, polyperfluoroethylene-propylene, and carbon nanotubes were placed in a twin-screw kneader and dispersed for 30 minutes at -30°C to obtain a flocculent mixture, which was added to the single-screw The extruder passes through four temperature control zones with temperatures of 60°C, 80°C, 90°C and 100°C, extrudes soft lumps from the die, and the soft lumps are molded at 100°C to obtain a sheet film, and the sheet film is passed through Roll pressing at 110°C to make a continuous film, the continuous film is adhered to aluminum foil through conductive adhesive, and roll pressing at 120°C to make a positive electrode. There is no N-methylpyrrolidone in the manufacturing process, and the consumption of N-methylpyrrolidone is reduced by 100% compared with the existing battery cathode preparation method. Such as figure 1 shown.

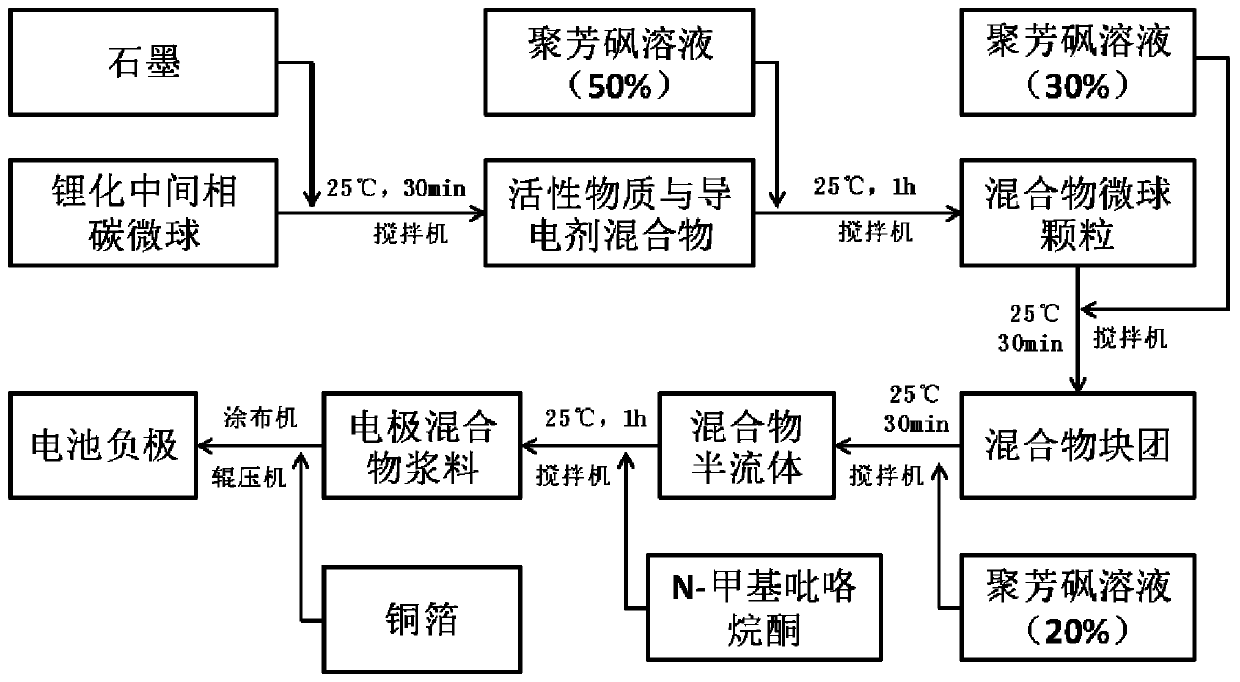

[0032] In this example, the negative electrode active mat...

Embodiment 2

[0036] In this example, the positive electrode active material lithium cobaltate, vinylidene fluoride trifluoroethylene copolymer and graphene were placed in an internal mixer and dispersed at 13°C for 1 hour to obtain a flocculent mixture. Disperse for 2 hours to obtain soft lumps. The soft lumps were molded at 105°C to obtain a sheet-like film. The sheet-like film was rolled at 105°C to form a continuous film. The continuous film was adhered to aluminum foil with conductive adhesive and rolled at 110°C to form a positive electrode. There is no N-methylpyrrolidone in the manufacturing process, and the consumption of N-methylpyrrolidone is reduced by 100% compared with the existing battery cathode preparation method. Such as figure 2 shown.

[0037]In this example, the negative electrode active material pre-lithiated graphite and carbon nanofibers were placed in a twin-screw kneader, dispersed for 30 minutes at a temperature of 25°C, added with 30% carboxymethyl cellulose so...

Embodiment 3

[0039] In this example, the positive electrode active materials lithium iron phosphate, ethylene-tetrafluoroethylene copolymer, and graphite were placed in a classifier, and airflow was impacted and dispersed for 30 minutes at 25°C to obtain a flocculent mixture, which was placed in banburying Machine, disperse at 40°C for 2 hours to obtain soft lumps, roll the soft lumps at 110°C to obtain a sheet film, roll the sheet film at 150°C to form a continuous film, and the continuous film is adhered to the aluminum foil through conductive adhesive. Roll pressing at 280°C to form a positive electrode. There is no N-methylpyrrolidone in the manufacturing process, and the consumption of N-methylpyrrolidone is reduced by 100% compared with the existing battery cathode preparation method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com