High-quality semi-polar two-dimensional ultra-thin indium nitrogen/gallium nitride laminated structure and preparation method thereof

A stacked structure, semi-polar technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor lasers, etc., can solve problems such as large stress, limited theoretical research results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] This embodiment provides a method for preparing a high-quality semipolar {11-22} two-dimensional ultra-thin indium nitride / gallium nitride stack structure, the steps are as follows:

[0068] (1) growing semipolar {11-22} gallium nitride thin films on the substrate;

[0069] (2) In the reaction chamber, a periodic two-dimensional ultra-thin indium nitride / gallium nitride stack structure is grown on the semipolar {11-22} gallium nitride film.

[0070] The growth process of the two-dimensional ultra-thin InN / GaN stack structure is:

[0071] growing an indium nitride layer;

[0072] Grow a thin layer of gallium nitride at the same growth temperature as the indium nitride layer;

[0073] GaN barrier layer is grown.

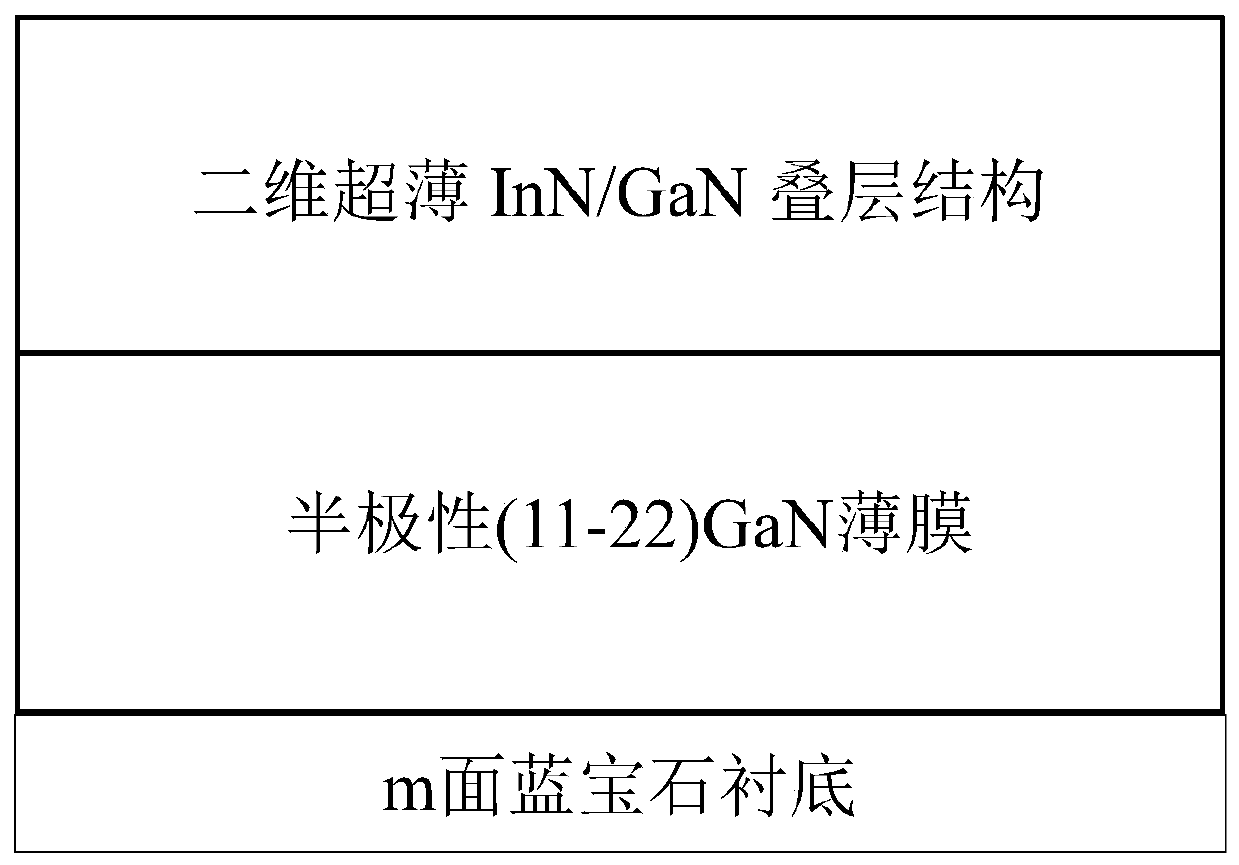

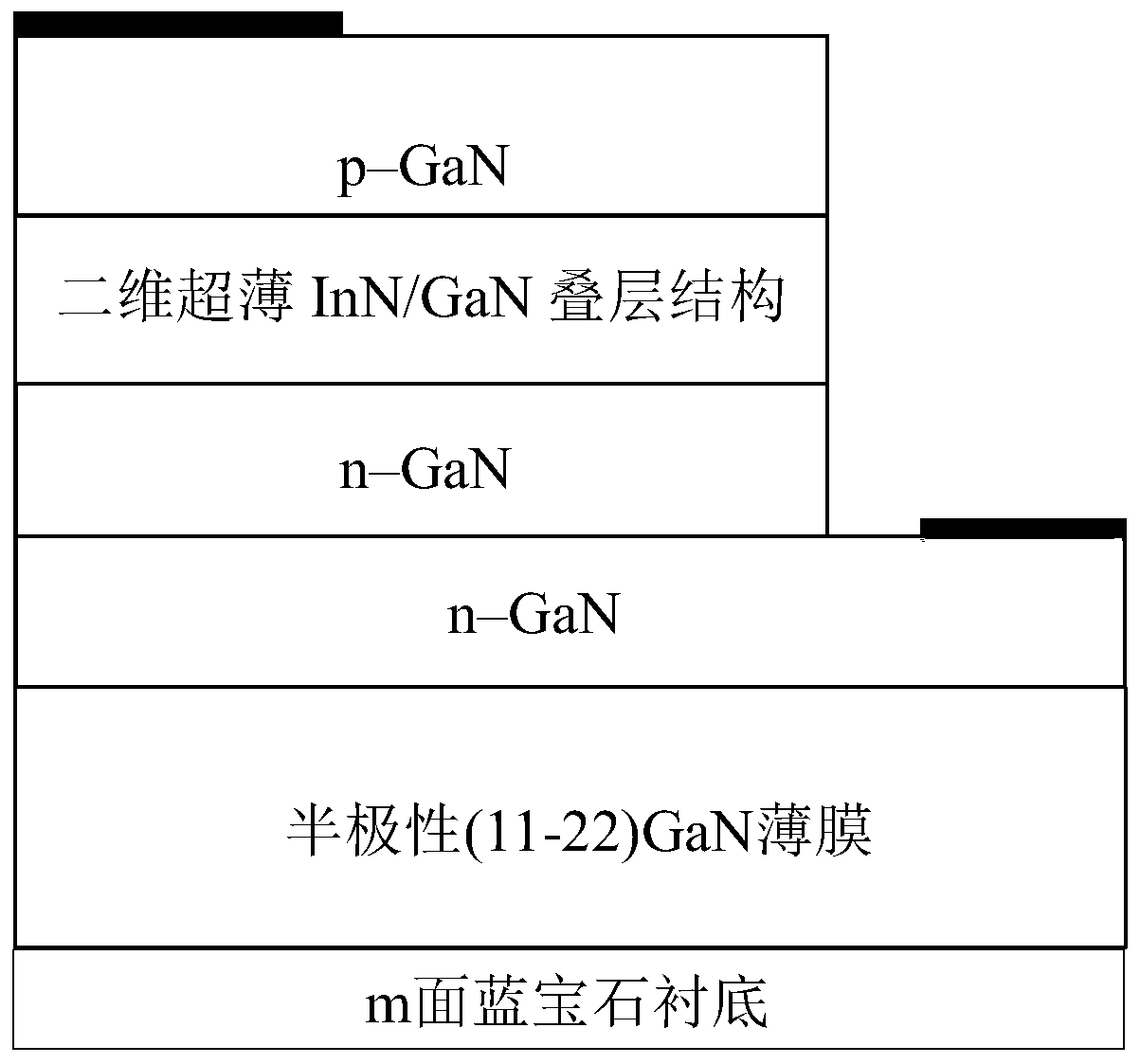

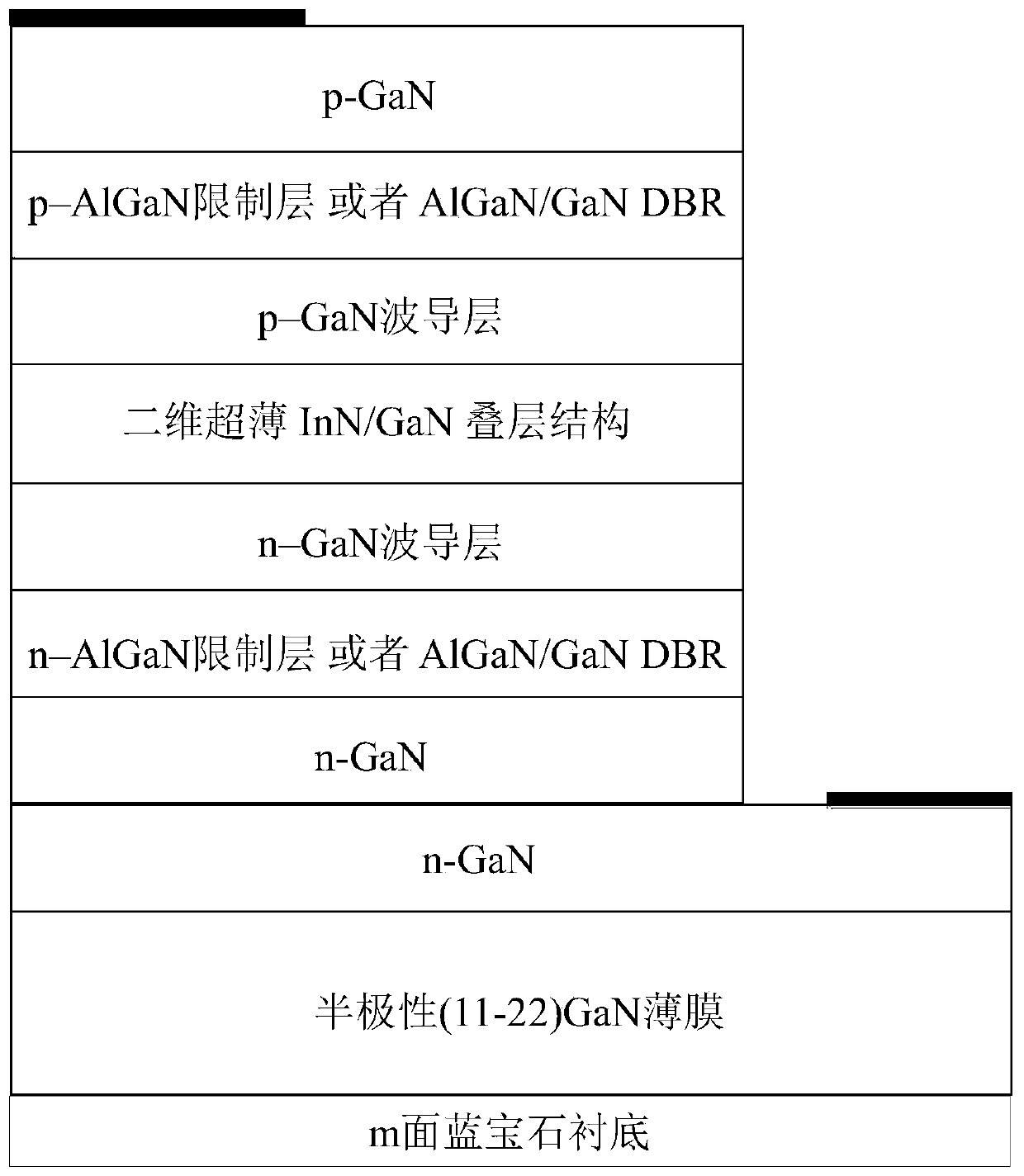

[0074] This embodiment also provides a high-quality semipolar {11-22} two-dimensional ultra-thin indium nitride / gallium nitride stack structure, such as figure 1 As shown, it includes a substrate, a semipolar gallium nitride film, and a two-dimensional ultra...

Embodiment 1

[0076] Example 1: High-quality semipolar {11-22} two-dimensional ultra-thin indium nitride / gallium nitride stacked structure

[0077] (1) growing semipolar {11-22} gallium nitride thin films on the substrate;

[0078] (2) A 20-period two-dimensional ultrathin indium nitride / gallium nitride stack structure was grown on the prepared semipolar {11-22} gallium nitride film;

[0079] The growth parameters of the two-dimensional ultrathin InN / GaN stack structure are as follows:

[0080] The pressure in the reaction chamber is in the range of 300Torr, and the two-dimensional ultra-thin indium nitride / gallium nitride stack structure is grown;

[0081] Indium nitrogen layer: the substrate temperature is 680° C.; the thickness of the indium nitrogen layer is ~1 nm.

[0082] Subsequently, before growing the gallium nitride barrier layer, a thin layer of gallium nitride is grown as a protective layer of indium nitrogen, the growth temperature is the same as that of the indium nitride la...

Embodiment 2

[0085] Example 2: High-quality semipolar {11-22} two-dimensional ultra-thin indium nitride / gallium nitride stacked structure

[0086] (1) growing semipolar {11-22} gallium nitride thin films on the substrate;

[0087] (2) A 30-period two-dimensional ultrathin indium nitride / gallium nitride stack structure was grown on the prepared semipolar {11-22} gallium nitride film;

[0088] The growth parameters of the two-dimensional ultrathin InN / GaN stack structure are as follows:

[0089] The pressure in the reaction chamber is in the range of 300Torr, and the two-dimensional ultra-thin indium nitride / gallium nitride stack structure is grown;

[0090] Indium nitrogen layer: the substrate temperature is 680° C.; the thickness of the indium nitrogen layer is ~0.6 nm.

[0091] Subsequently, before growing the gallium nitride barrier layer, a thin layer of gallium nitride is grown as a protective layer of indium nitrogen, the growth temperature is the same as that of the indium nitride ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com