Self-adhesive polymer modified bituminous waterproof roll material and preparation method thereof

A technology of modified asphalt and waterproof membrane, which is applied in asphalt coatings, coatings, textiles and papermaking, etc. It can solve the problems of low small molecule mobility and self-adhesive membranes that cannot have high mechanical properties at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

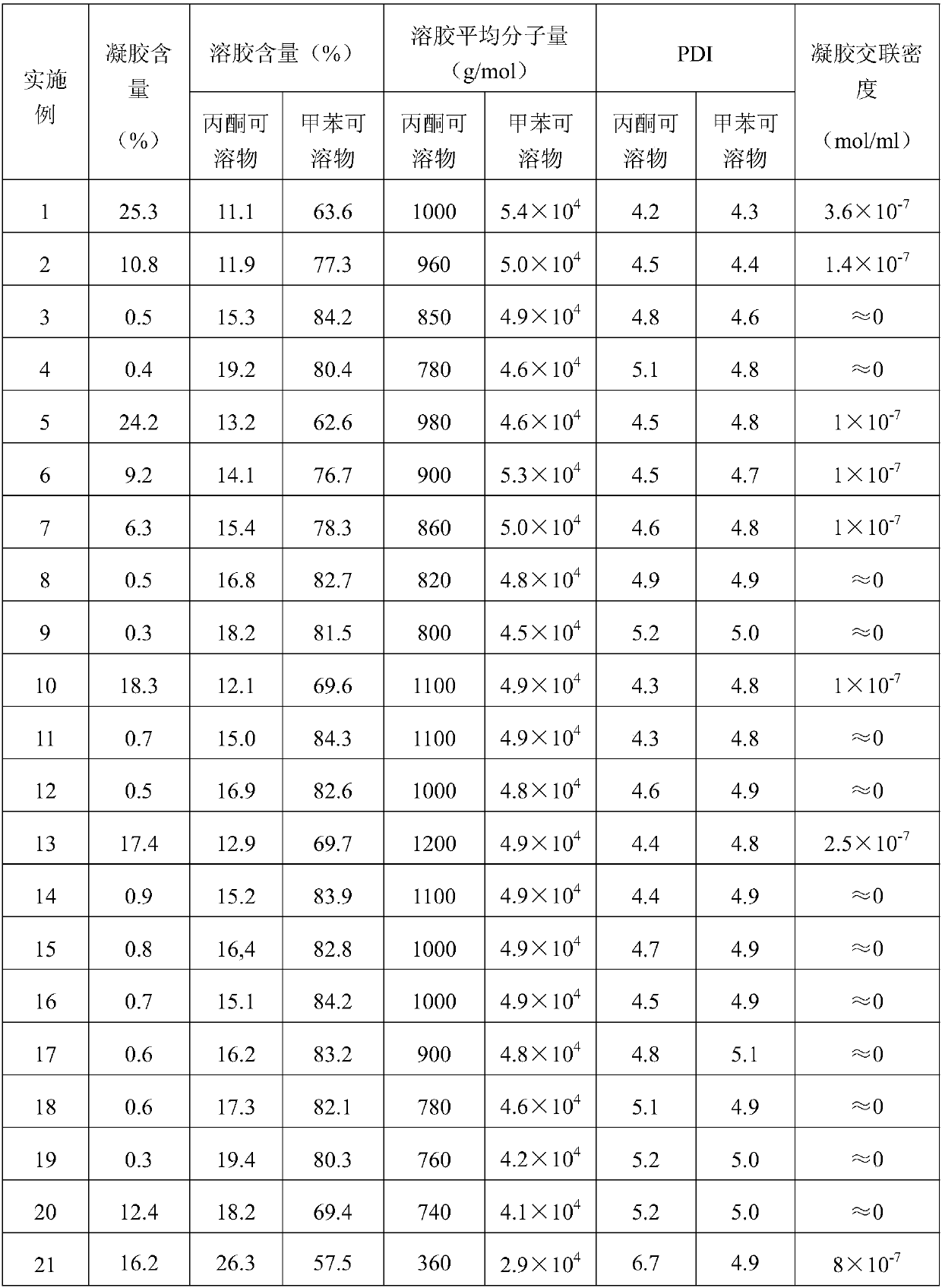

Examples

preparation example Construction

[0041] According to another aspect of the present invention, there is also provided a method for preparing a self-adhesive polymer-modified asphalt waterproof membrane, which includes the following steps: mixing and dispersing asphalt, a modifier and a first filler to obtain a rubber compound; and The glue is impregnated or coated on the surface of the felt cloth, and the roll is formed to obtain a coiled material.

[0042] In the above preparation method, besides asphalt and the first filler, modifiers are also used as raw materials. The modifier uses linearized active rubber, which is obtained by desulfurization treatment of waste rubber powder, and the weight percentage of linearized molecules in the linearized active rubber is ≥ 75%. The linearized reactive rubber basically belongs to linearized macromolecules or has a high content of linearized macromolecules. It can form a tight interface with other components when used for self-adhesive membrane modification, so it can ...

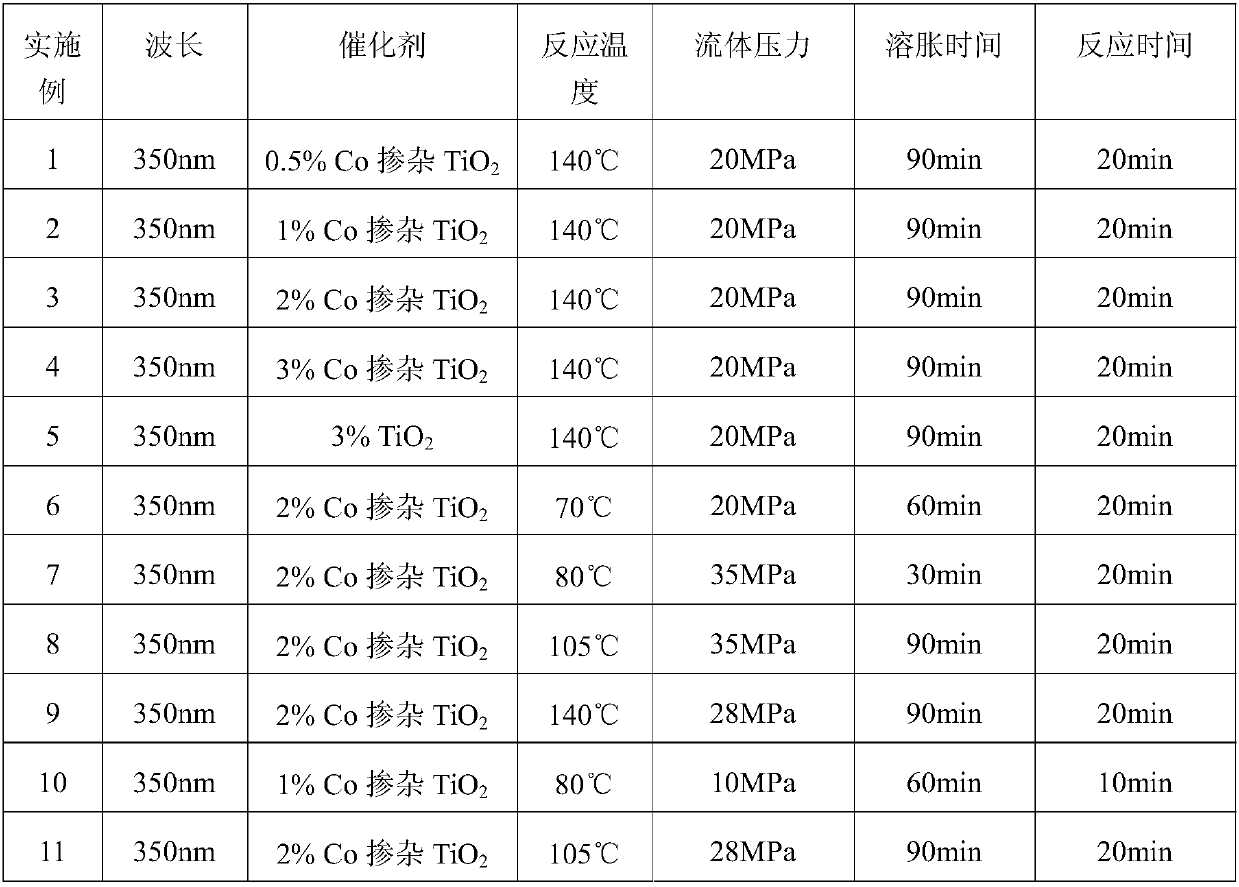

Embodiment 1 to 17

[0064] All utilize following method to carry out waste rubber desulfurization regeneration treatment in these embodiments:

[0065] Step 1: Put 80-mesh waste tire rubber powder and photocatalyst into the high-speed mixing unit, stir at a stirring speed of 1000rpm for 20 minutes until the temperature reaches 70°C, stop stirring, put the material into the cooling unit to cool and discharge, and obtain a mixture ;

[0066] Step 2: Put the mixture into a supercritical carbon dioxide reactor, use a high-pressure pump to inject carbon dioxide gas into the reactor to adjust the pressure in the reactor, and raise the temperature at the same time to convert the carbon dioxide gas into a supercritical state; start stirring to make the mixture in the supercritical state Swell in critical carbon dioxide to obtain a swelling mixture;

[0067] Step 3: Maintain the above-mentioned supercritical carbon dioxide environment, start the built-in ultraviolet light source to irradiate the swelling...

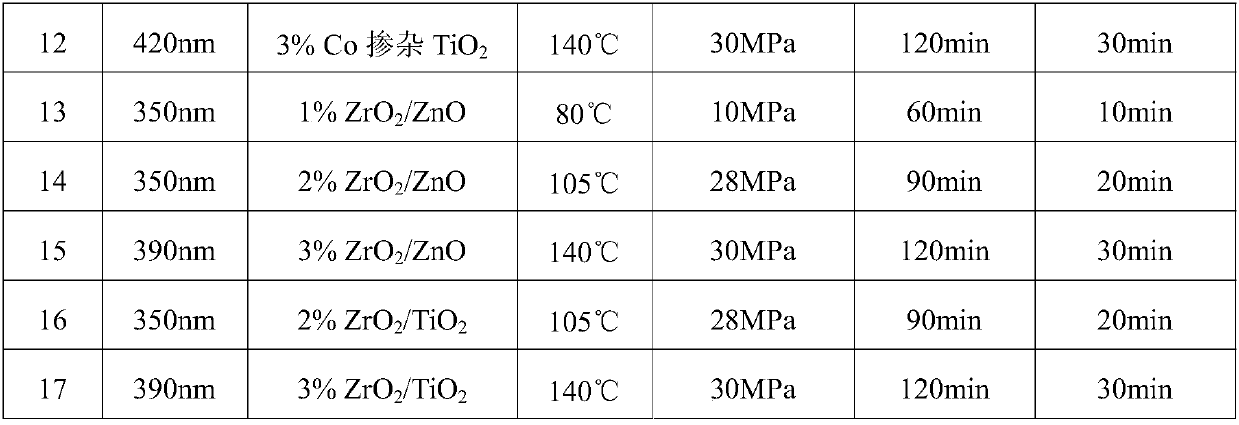

Embodiment 18

[0074] The technological process in this embodiment is the same as embodiment 9, and difference is:

[0075] Step 1: Put 120 mesh waste tire rubber powder and photocatalyst into the high-speed mixing unit, stir at a stirring speed of 700 rpm for 30 minutes until the temperature reaches 60°C, stop stirring, put the material into the cooling unit to cool and discharge, and obtain mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com