Preparation method of tungsten-based sealing material chemical Ni-P coating

A sealing material and chemical plating technology, applied in the field of materials, can solve the problems of inactive metal tungsten chemical properties and poor pretreatment effect, and achieve the effect of smooth and dense coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

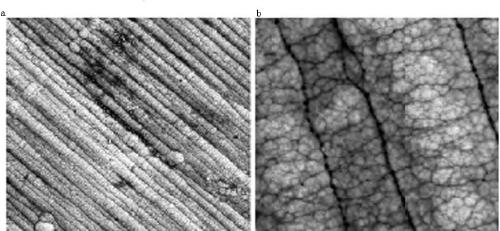

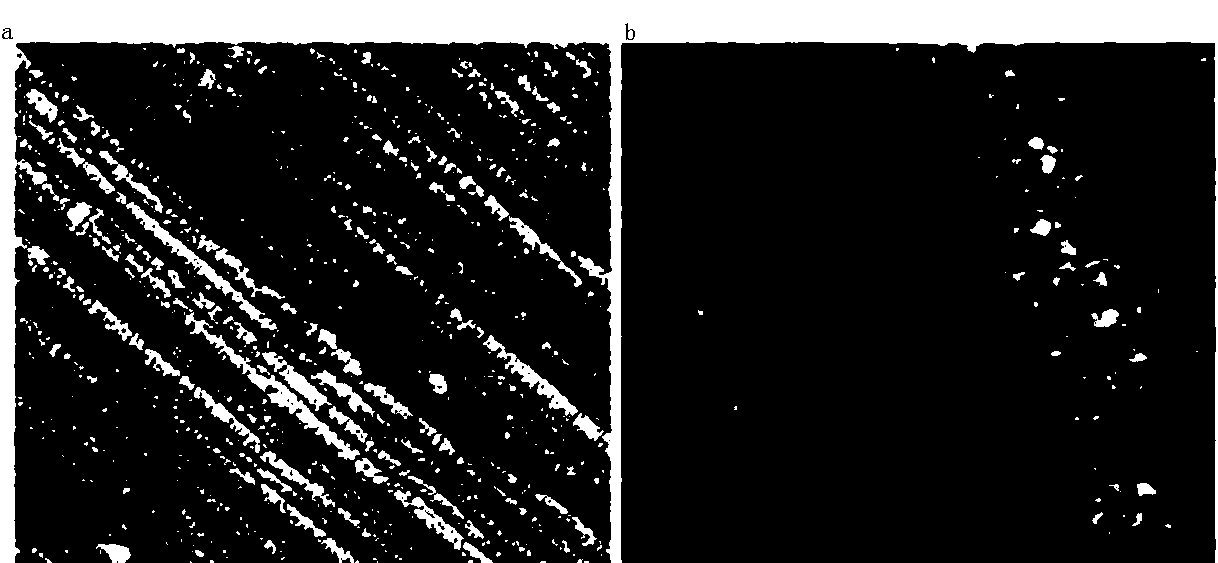

Image

Examples

Embodiment 1

[0014] The preparation method of the electroless Ni-P coating on the tungsten-based sealing material specifically includes the following steps.

[0015] Step 1. Preparation of the primary metallization layer: Soak an alumina thin porcelain plate with an alumina content of 98% in an ammonia solution with a concentration of 70% for 30 minutes; select tungsten as the sealing metal, and use conventional activated molybdenum in this field - Metallize it once by manganese method; carefully weigh the raw materials used in the metallization formula, grind it in an agate mortar for 2 hours, add an appropriate amount of diethyl oxalate, and add 10ml of nitrocellulose solution after it is completely soaked , to form a paste with a certain viscosity; use the manual pen paste process to coat, and then sinter the coated sample in a horizontal hydrogen furnace at a sintering temperature of 180°C; after the primary metallization process, the obtained The metal sheet is cut into 10mm×10mm.

...

Embodiment 2

[0020] The preparation method of the electroless Ni-P coating on the tungsten-based sealing material specifically includes the following steps.

[0021] Step 1. Preparation of the primary metallization layer: Soak an alumina thin ceramic plate with an alumina content of 97% in an ammonia solution with a concentration of 60% for 25 minutes; select tungsten as the sealing metal, and use conventional activated molybdenum in this field - Metallize it once by manganese method; carefully weigh the raw materials used in the metallization formula, grind it in an agate mortar for 2 hours, add an appropriate amount of diethyl oxalate, and add 15ml of nitrocellulose solution after it is completely soaked , to form a paste with a certain viscosity; use the manual pen paste process to coat, and then sinter the coated sample in a horizontal hydrogen furnace at a sintering temperature of 190°C; after the primary metallization process, the obtained The metal sheet is cut into 10mm×10mm.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com