Ceramic whisker/ferromagnetic metal composite wave-absorbing material and preparation method thereof

A composite wave absorbing material and ceramic whisker technology, which is applied in the parts, shielding, instruments and other directions of the instrument, can solve the problems of low wave absorption efficiency, difficult industrial production, complicated preparation process, etc., and achieves the improvement of complex dielectric constant, The effect of improving the complex magnetic permeability and the smooth and dense coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

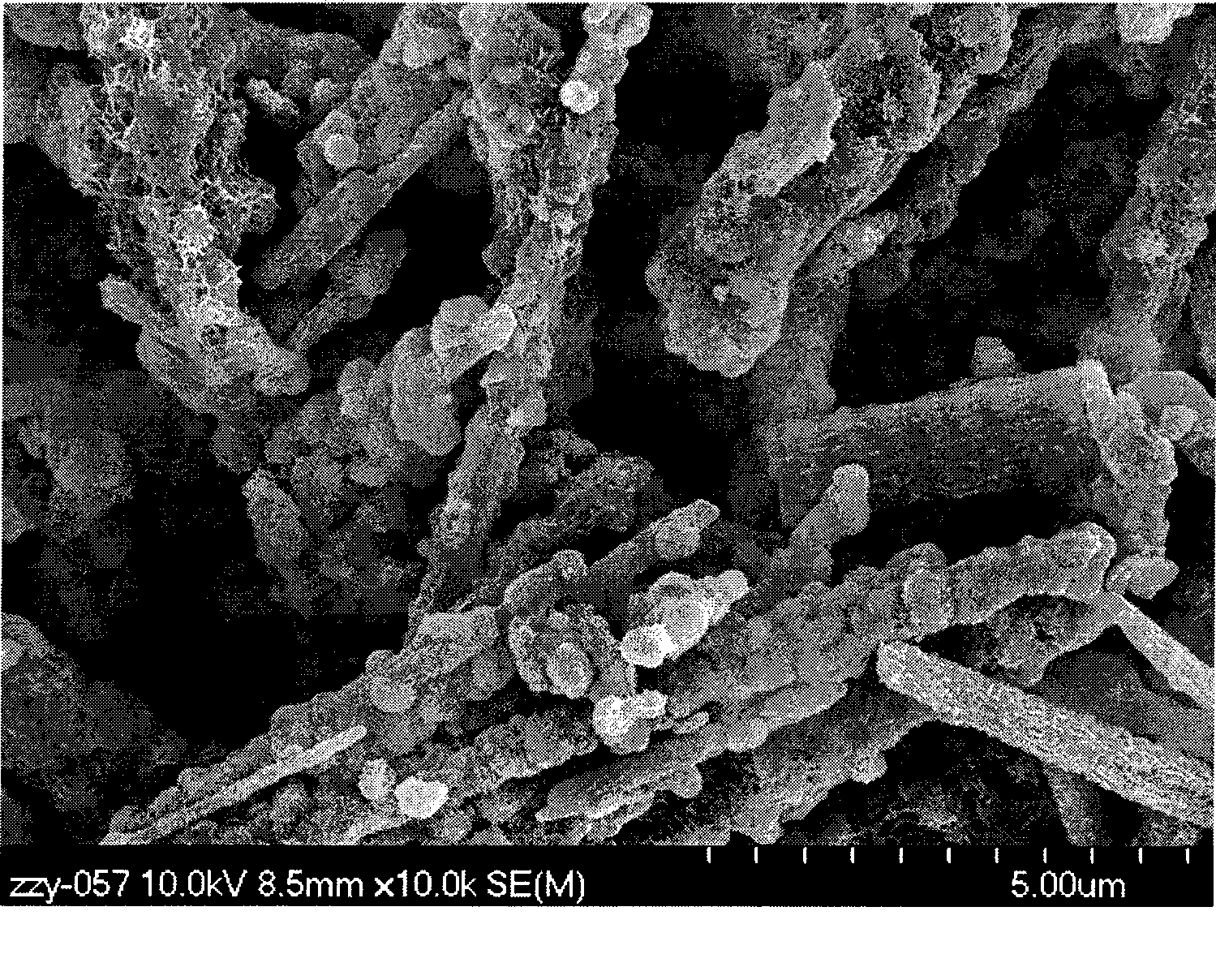

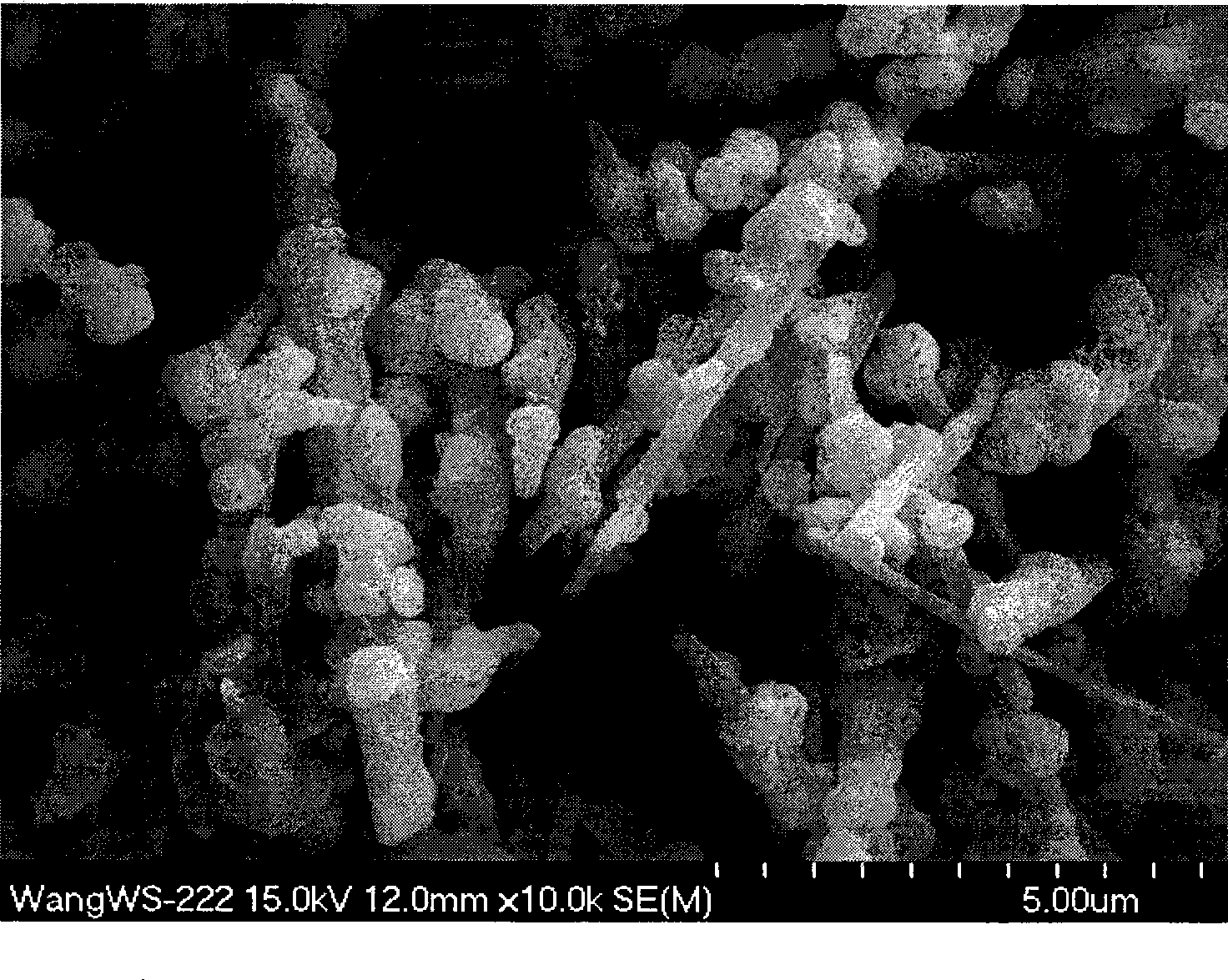

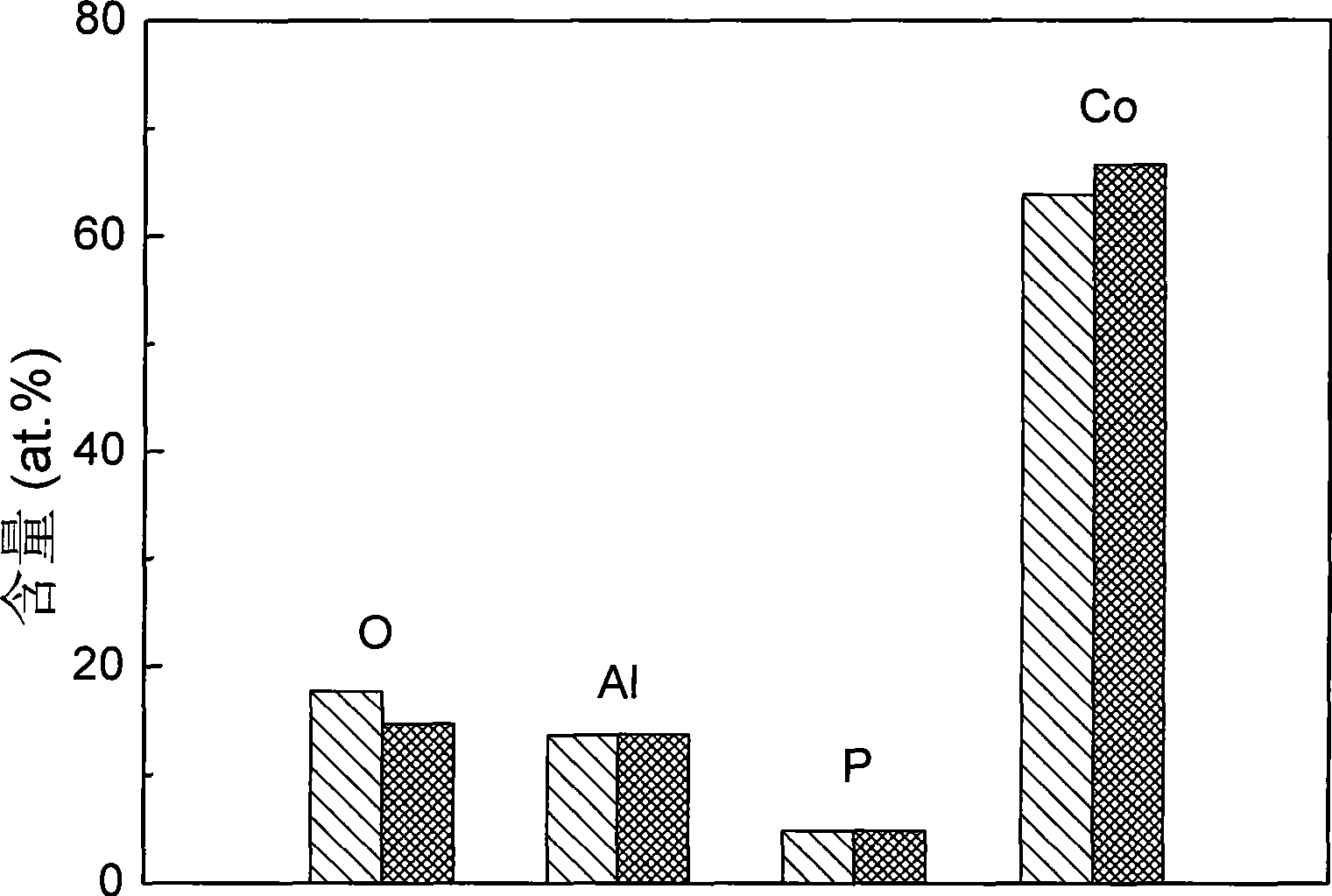

[0009] Embodiment 1: In this embodiment, the ceramic whisker / ferromagnetic metal composite wave-absorbing material is made of ceramic whisker coated with a ferromagnetic metal coating. The ferromagnetic metal coating described in this embodiment is Co or FeCo.

specific Embodiment approach 2

[0010] Embodiment 2: This embodiment differs from Embodiment 1 in that the thickness of the ferromagnetic metal coating is 0.05 μm˜1 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the ceramic whiskers are SiC whiskers or Al 18 B 4 o 33 whiskers. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com