Two-gear differential coupling hybrid power transmission system with P3 structure

A technology of hybrid power and transmission system, which is applied in the arrangement of multiple different prime movers of hybrid power vehicles, power plants, and general power plants, etc., can solve the problems of easy transmission interruption, high cost, high material and processing requirements, and achieves The effect of reducing the difficulty and cost of manufacturing, reducing the space occupied, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the technical means and effect that the present invention adopts in order to achieve the intended invention purpose are further elaborated.

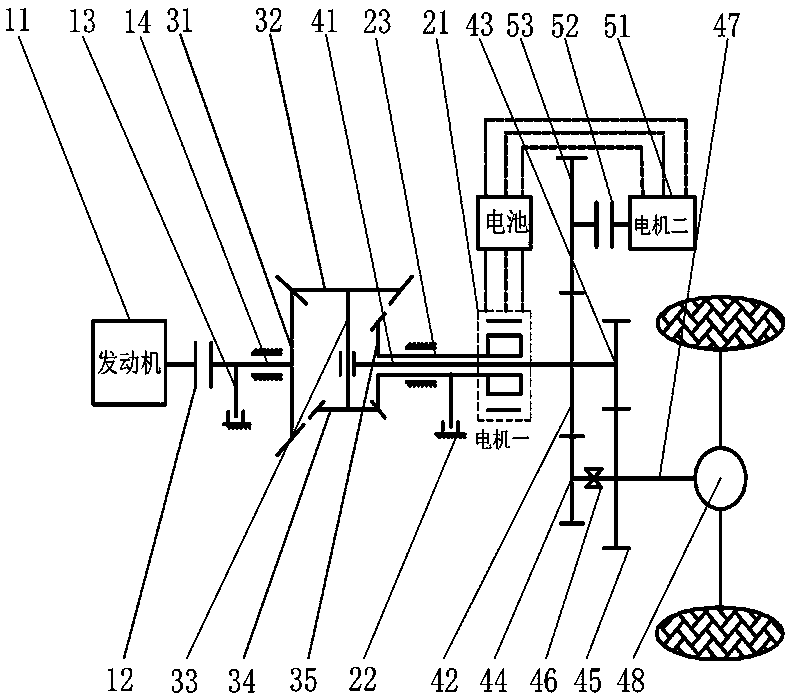

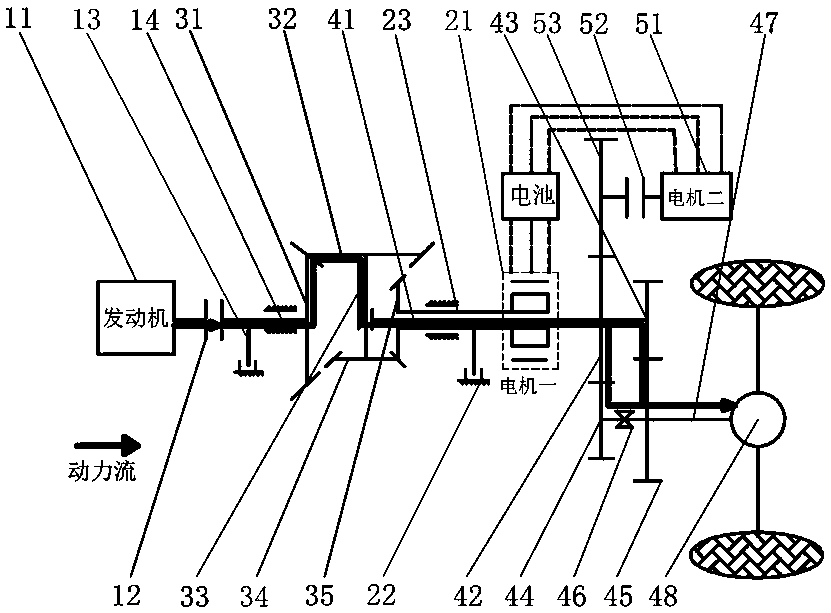

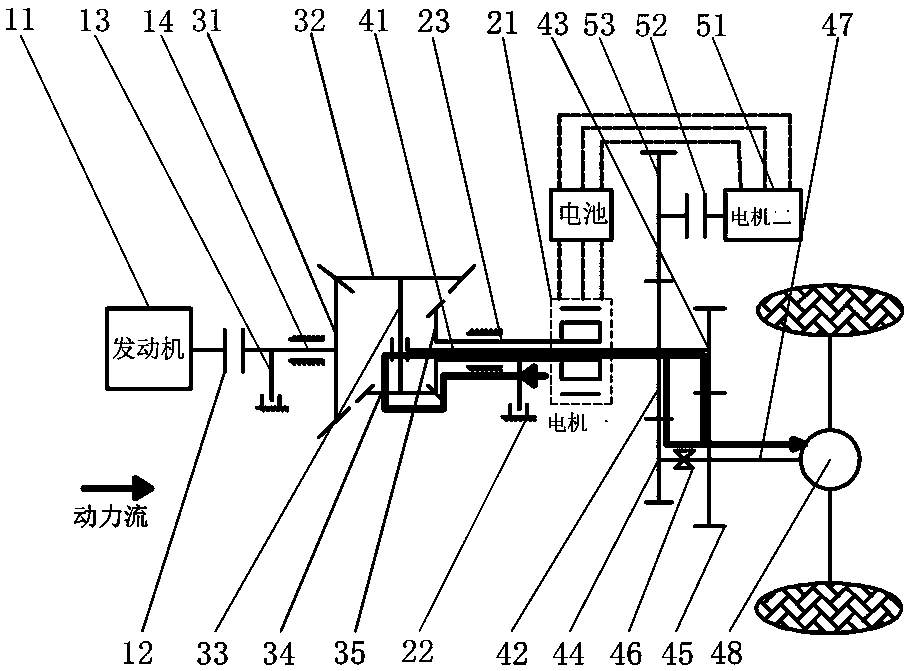

[0030] see figure 1 A P3 structure two-speed differential coupling hybrid power transmission system includes an engine power input mechanism, a first electric motor power input mechanism, a second electric motor power input mechanism, a power coupling mechanism and a power output mechanism.

[0031] The engine power input mechanism includes a first clutch 12 connected to the output shaft of the engine 11 , and a first brake 13 is fixedly installed on the first transmission shaft 14 .

[0032] The first motor power input mechanism comprises a first motor 21, a transmission shaft 23 and a second brake 22, the motor rotor of the first motor 21 is coaxially connected to one end of the transmission shaft 23, and the second brake 22 is fixedly mounted on the transmission shaft 23; Transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com