SLA full-color 3D printing method and device based on inkjet color interlayer

A 3D printing and color technology, applied in the direction of 3D object support structure, additive manufacturing, manufacturing tools, etc., can solve the problem that color printing objects cannot be generated, and achieve the effect of simple structure, delicate color and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0118] [best practice]

[0119] Below in conjunction with accompanying drawing, the present invention will be further described with regard to preferred embodiment:

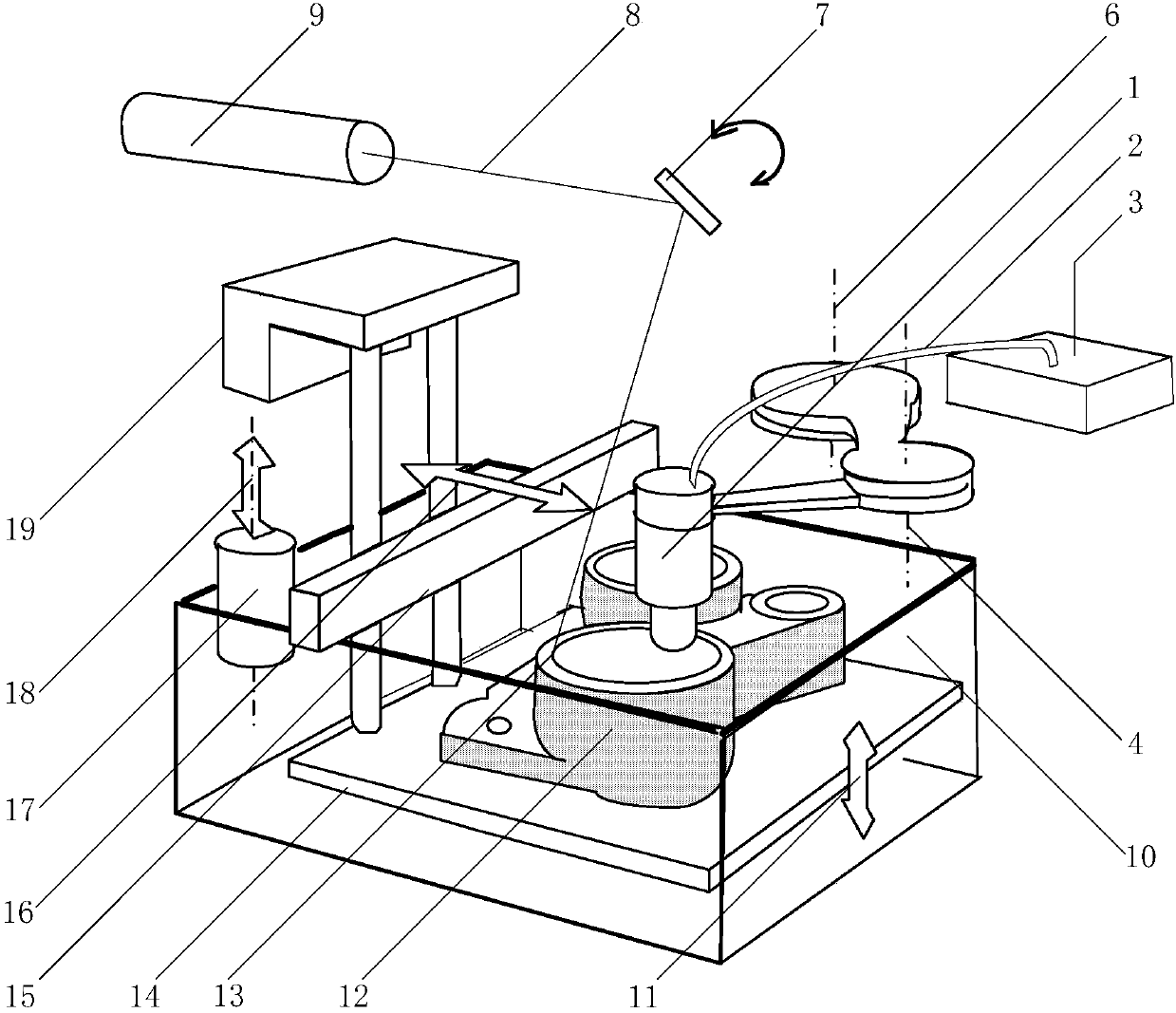

[0120] Such as figure 1 Shown:

[0121] The color nozzle (1) used for printing color ink is installed on a mechanism that can perform two-dimensional plane motion and a vertical parallel axis motion synthesis. They are composed of a moving rotation axis A (4) and a fixed rotation axis (6). The planar motion system; the ink storage box (3) transmits the color (UV) ink to the color nozzle (1) through the ink delivery pipe (2);

[0122] Driven by the motor, the lifting platform bracket (19) supports the lifting platform (14) and carries the formed object (12) down to the height of one printing layer each time, forming a vertical direction of the lifting movement direction (11); In order to ensure the smoothness of the resin liquid level, the resin scraper (15) moves along the horizontal direction shown in the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com