Bamboo chip defibering, and bamboo green and bamboo yellow removing pressing roll device and defibering machine

A technology for pressing rollers and removing bamboo greens, which is applied in mechanical equipment, sugarcane machining, wood processing appliances, etc., can solve the problems of unclean removal, waste of materials, irregular shapes, etc., and achieve the effect of saving processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

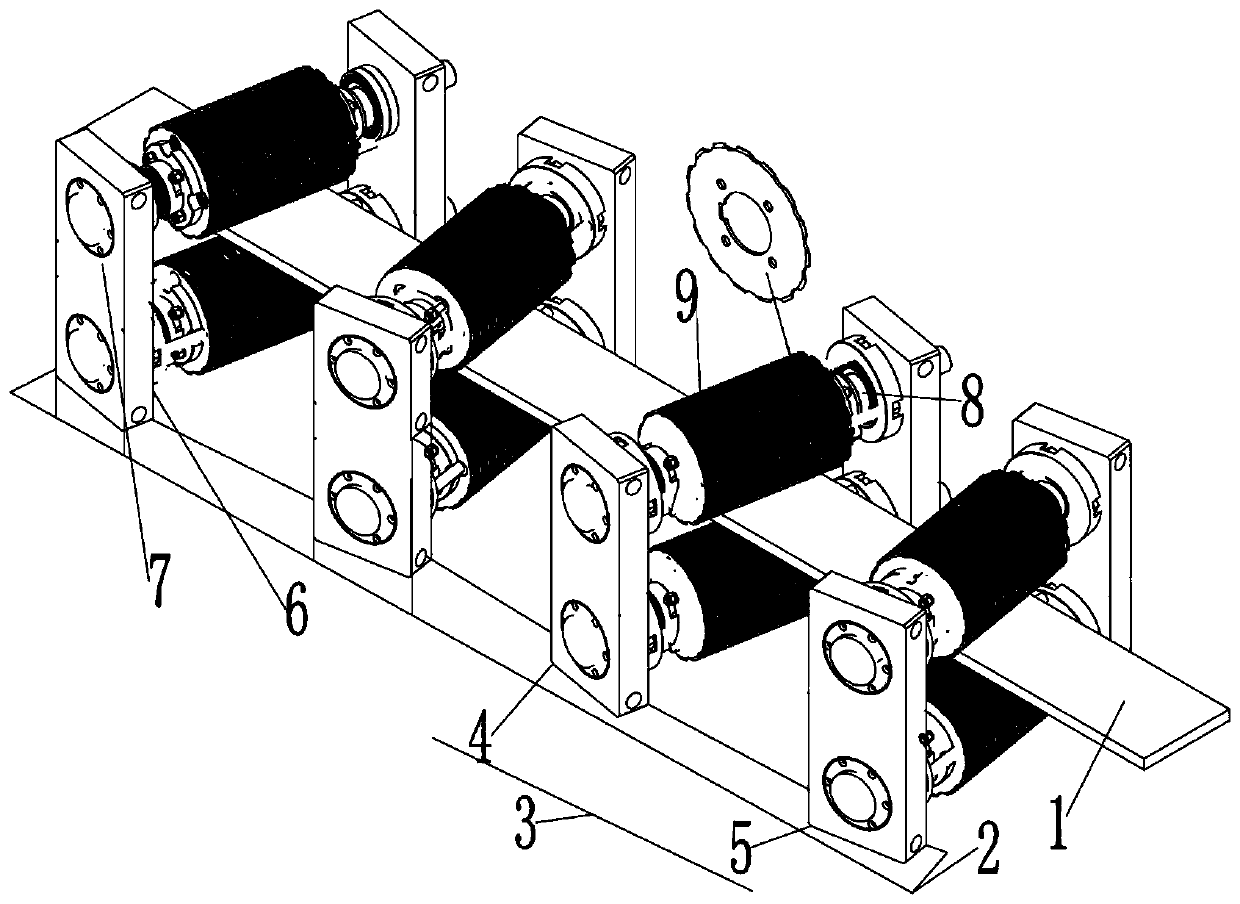

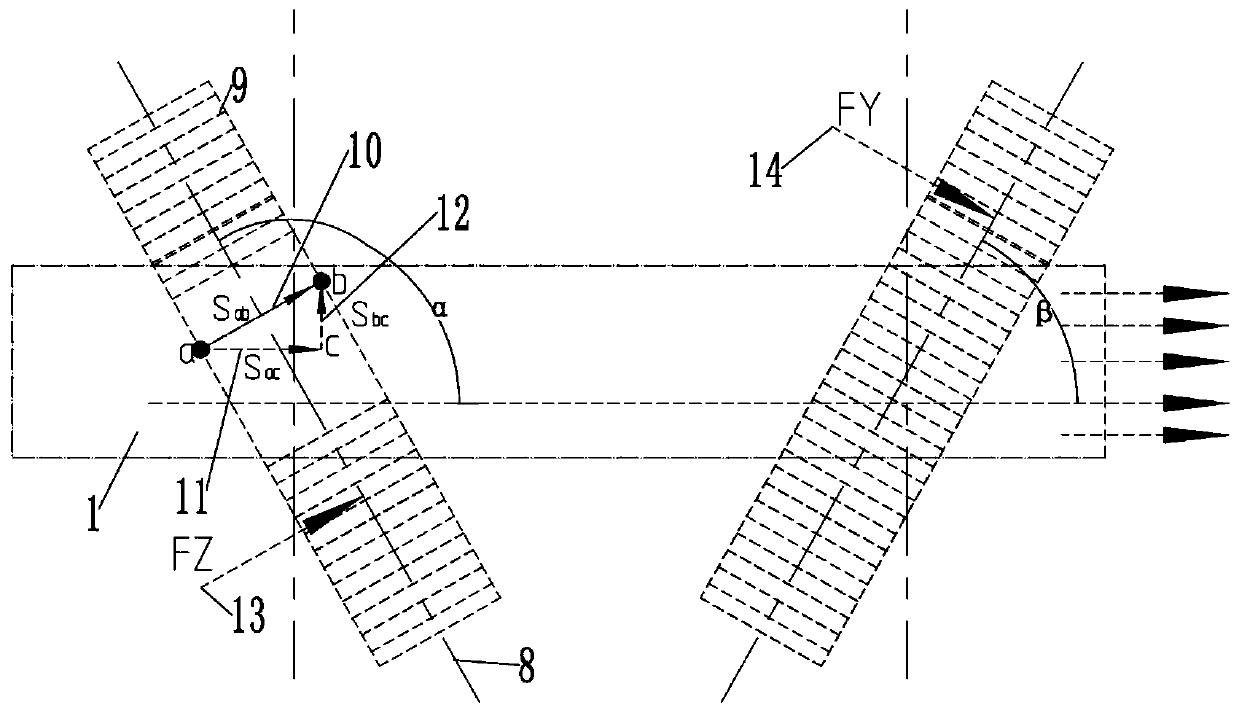

[0027] like Figure 1-2 As shown, for the problem of removing bamboo green and bamboo yellow, the details are as follows Figure 1-2 , the present embodiment decomposes and removes bamboo green and bamboo yellow press roll device, comprises frame assembly 2, and is arranged on the frame assembly 2 and the tooth profile that bamboo chip 1 upper surface and / or lower surface are decomposed Squeeze roller group 3; That is, it can be to deflate the bamboo chip 1 on one side or both sides.

[0028] The toothed press roll group 3 includes a pair and is arranged symmetrically on the left inclined press roll set 4 and the right inclined press roll set 5; as equivalent, the left inclined press roll set 4 and the right inclined press roll set 5 can be exchanged.

[0029] Angle α=180° between the center line of the main roller axis 8 of the left inclined pressure roller group 4 and the forward direction of the bamboo chip 1-the center line of the main roller axis 8 of the right inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com