Multi-adhesive-tape applicator

A technology of gluing machine and gluing mechanism, which is applied in the direction of primary battery, sustainable manufacturing/processing, electrochemical generator, etc., can solve the problems of low work efficiency, unrealizable, unsatisfactory demand, etc., to improve production efficiency, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. Preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein.

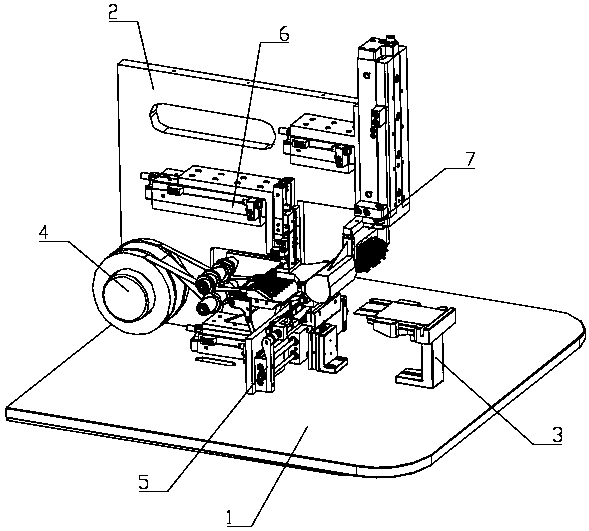

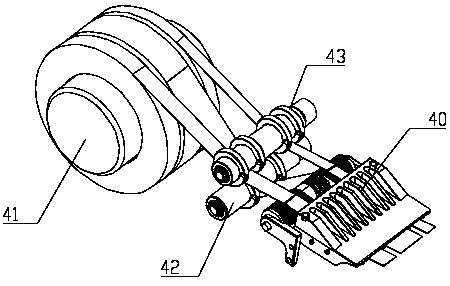

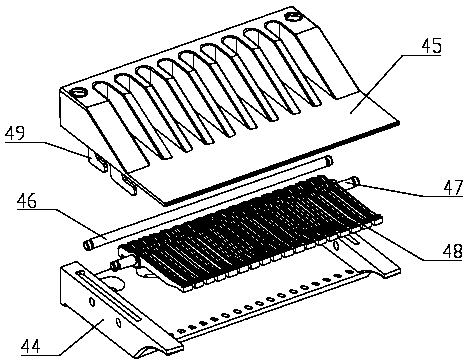

[0024] Such as figure 1 As shown, in a preferred embodiment, the multiple adhesive tape applicator of the present invention mainly includes a base 1, a support plate 2, a positioning seat 3, a feeding mechanism 4, a cutting mechanism 5, a gluing mechanism 6, and a brushing mechanism 7. Wherein, the positioning seat 3 is fixed on the base 1, and it is used for placing the battery to be processed. The discharging mechanism 4 is arranged opposite to the positioning seat 3, the cutting mechanism 5 is arranged between the discharging mechanism 4 and the positioning seat 3, the glue application mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com