Product Driven Material Separation Transport Direct Methanol Fuel Cell and Method of Operation

A methanol fuel cell, methanol technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of blending, uneven methanol vapor concentration, and insufficient methanol reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

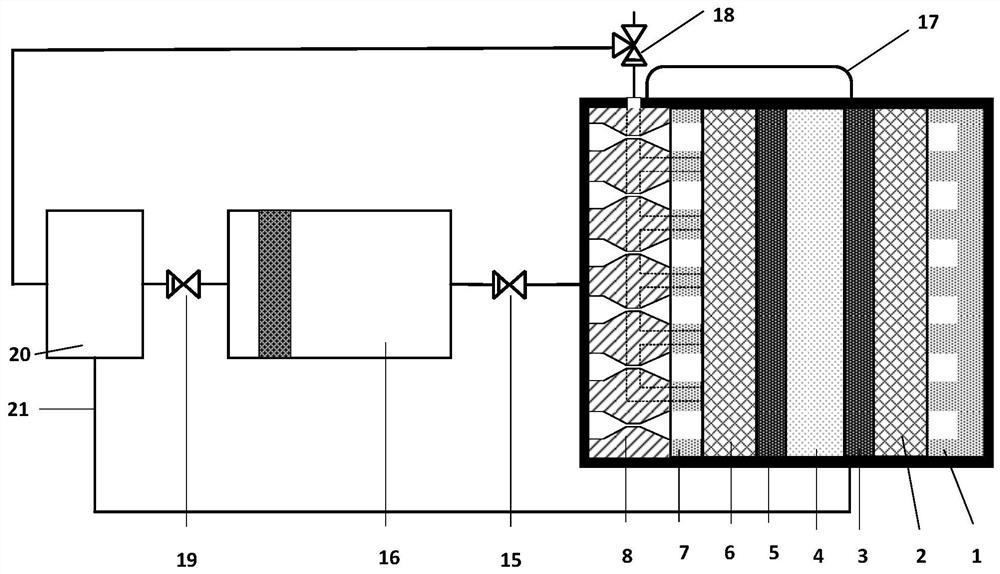

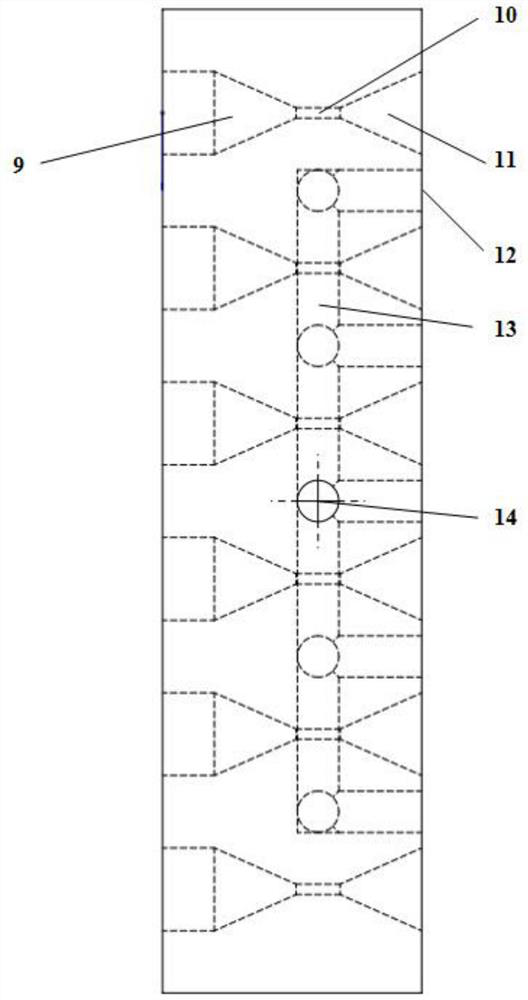

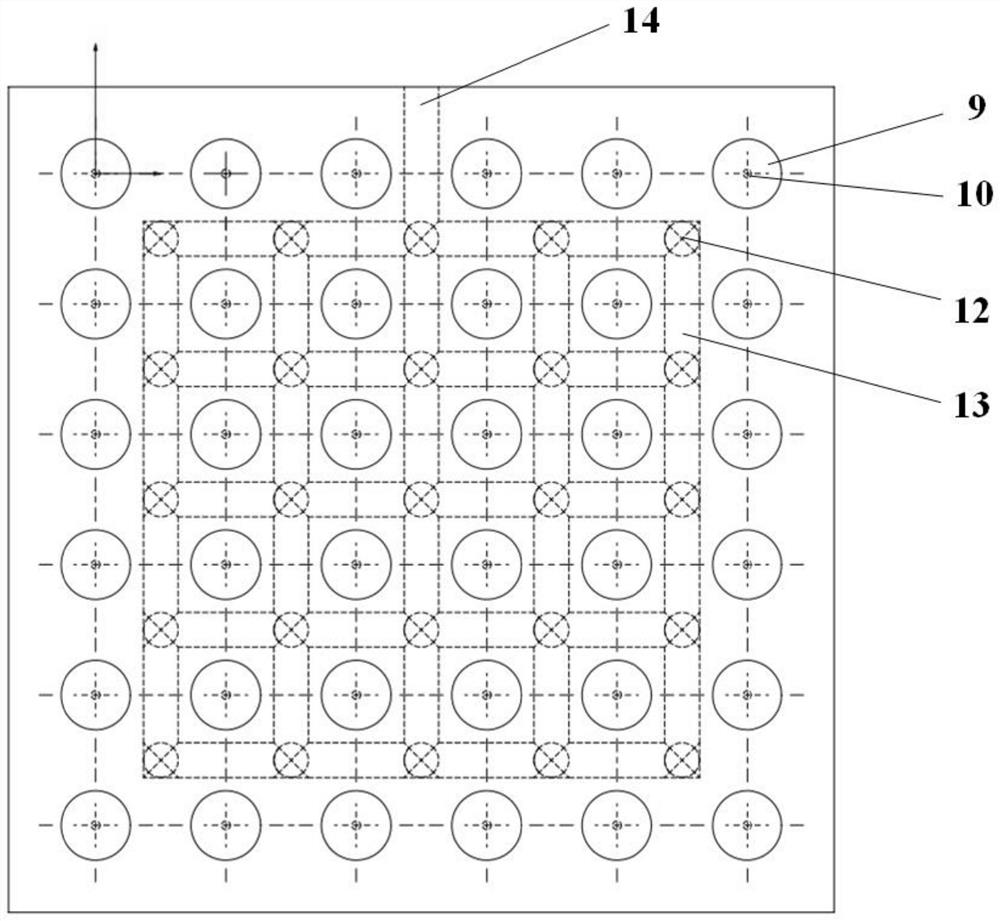

[0051] see figure 1 , the product-driven material separation and transmission direct methanol fuel cell of the present invention comprises a methanol fuel cell body and a cathode collector plate 1, a cathode diffusion layer 2, a cathode catalyst layer 3, a diaphragm 4, and an anode catalyst layer arranged on the methanol fuel cell body 5. The anode diffusion layer 6 and the anode current collector 7; wherein the diaphragm 4 is connected to the cathode catalyst layer 3 and the anode catalyst layer 5, the cathode diffusion layer 2 is connected to the cathode current collector 1 and the cathode catalyst layer 3, and the anode diffusion layer 6 is connected to the cathode catalyst layer 3. The anode catalytic layer 5 is connected to the anode current collecting plate 7 , and a methanol evaporation zone 8 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com