Stannic oxide/carbonized aerogel core-shell structure composite sulfur electrode material, and preparation method and application thereof

A technology of core-shell structure and carbonized gas, which is applied to battery electrodes, structural parts, circuits, etc., can solve the problems of poor cycle stability of lithium-sulfur batteries, achieve good cycle stability, improve electrical conductivity, and achieve effective transmission effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A tin oxide / carbonized airgel core-shell structure composite sulfur electrode material, the shell layer of the electrode material is tin oxide, the core layer is carbonized airgel microspheres, and monomeric sulfur is uniformly dispersed in the carbonized airgel microspheres The mass of monomeric sulfur accounts for 60-80% of the total mass of the core-shell structure composite sulfur electrode material.

[0047] In this embodiment, the monomeric sulfur is evenly dispersed in the carbonized airgel microspheres, and the conductivity of the sulfur electrode is improved through the compounding of the monomeric sulfur and the carbonized aerogel, and the carbonized aerogel can also inhibit the electrochemical reaction of sulfur. The volume expansion during the reaction prevents the structure of the electrode material from being destroyed; the tin oxide shell layer confines sulfur in the carbonized airgel core layer, which can inhibit the seepage of sulfur during charge and di...

Embodiment 2

[0049] A tin oxide / carbonized airgel core-shell structure composite sulfur electrode material, the shell layer of the electrode material is tin oxide, the core layer is carbonized airgel microspheres, and monomeric sulfur is uniformly dispersed in the carbonized airgel microspheres Inside, the mass of monomeric sulfur accounts for 65% of the total mass of the core-shell structure composite sulfur electrode material.

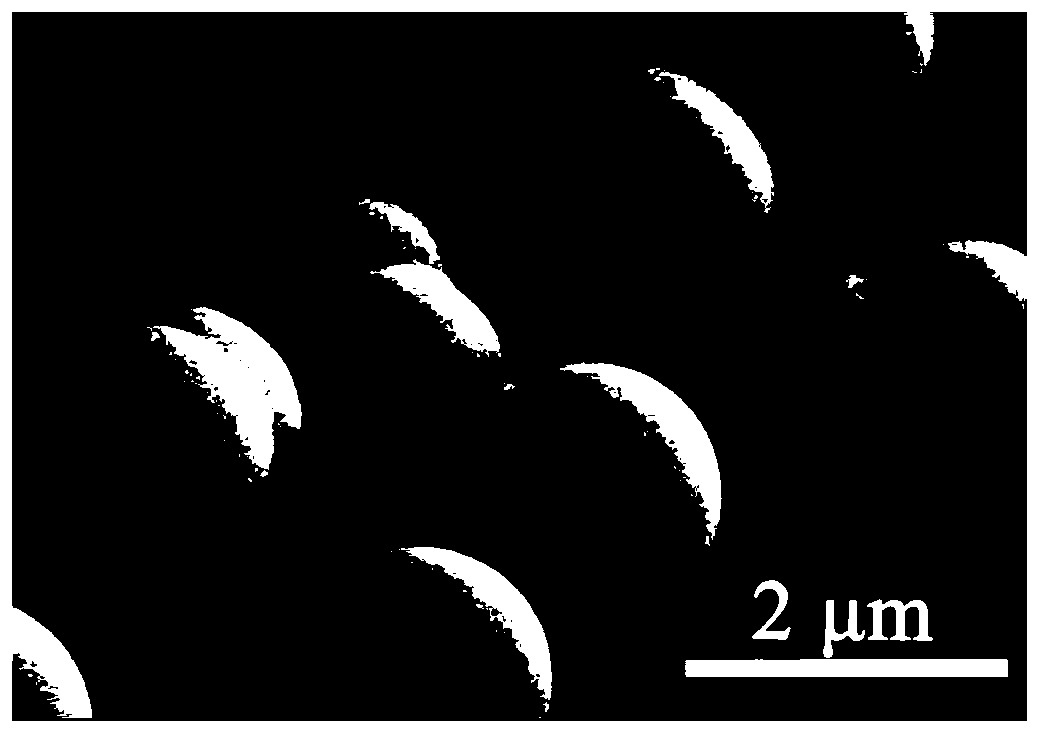

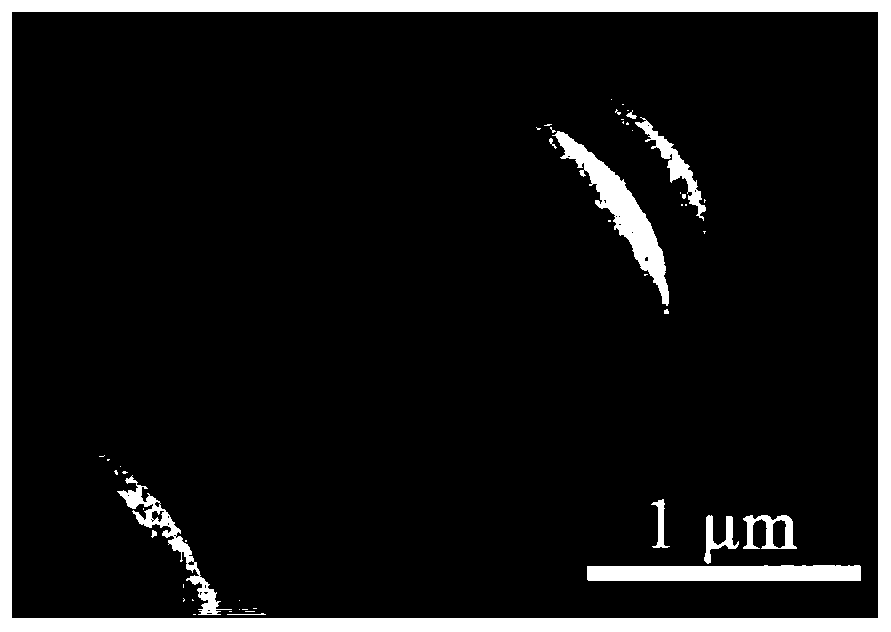

[0050] In this embodiment, the thickness of the tin oxide shell layer is 5-15 nm, and the diameter of the carbonized airgel microspheres is 1-2 μm.

Embodiment 3

[0052] The preparation method of a tin oxide / carbide aerogel core-shell structure composite sulfur electrode material provided in this example, the steps are as follows:

[0053] Step 1. Synthesis of carbonized airgel microspheres

[0054] Mix resorcinol, formaldehyde and water according to a certain molar volume ratio, add a certain mass of catalyst to the mixing system and mix to obtain a suspension; place the suspension at a certain temperature for aging treatment for a certain period of time, collect The precipitate in the suspension is washed with absolute ethanol and dried; the dried precipitate is placed in an inert gas atmosphere and calcined at a certain temperature for a certain period of time to obtain a carbonized gas with a certain spherical diameter gel microspheres;

[0055] Step 2. Preparation of tin oxide / carbonized airgel core-shell microspheres

[0056] Put the carbonized airgel microspheres prepared in step 1 into the acid solution for surface activation;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com