Organic solar cell with MXene as anode modification layer material and manufacturing method thereof

An anode modification layer, solar cell technology, applied in circuits, photovoltaic power generation, electrical components and other directions, can solve the problems of energy conversion efficiency attenuation, device performance instability, increase battery manufacturing difficulty and production cost, etc., to reduce interface capacity, The effect of improving photoelectric conversion efficiency and improving charge transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

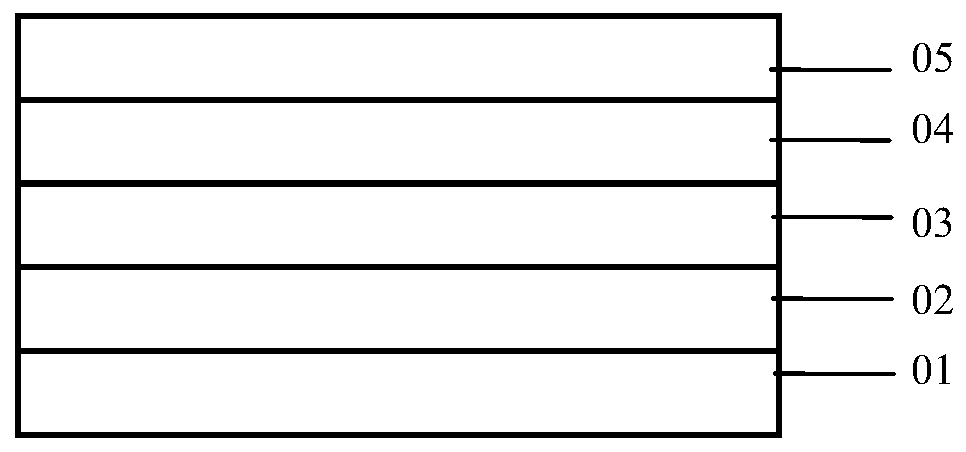

[0038] The organic solar cell device structure in which MXene is used as the anode modification layer material in Example 1 is: ITO / MXene / P3HT:PCBM / Ca / Al.

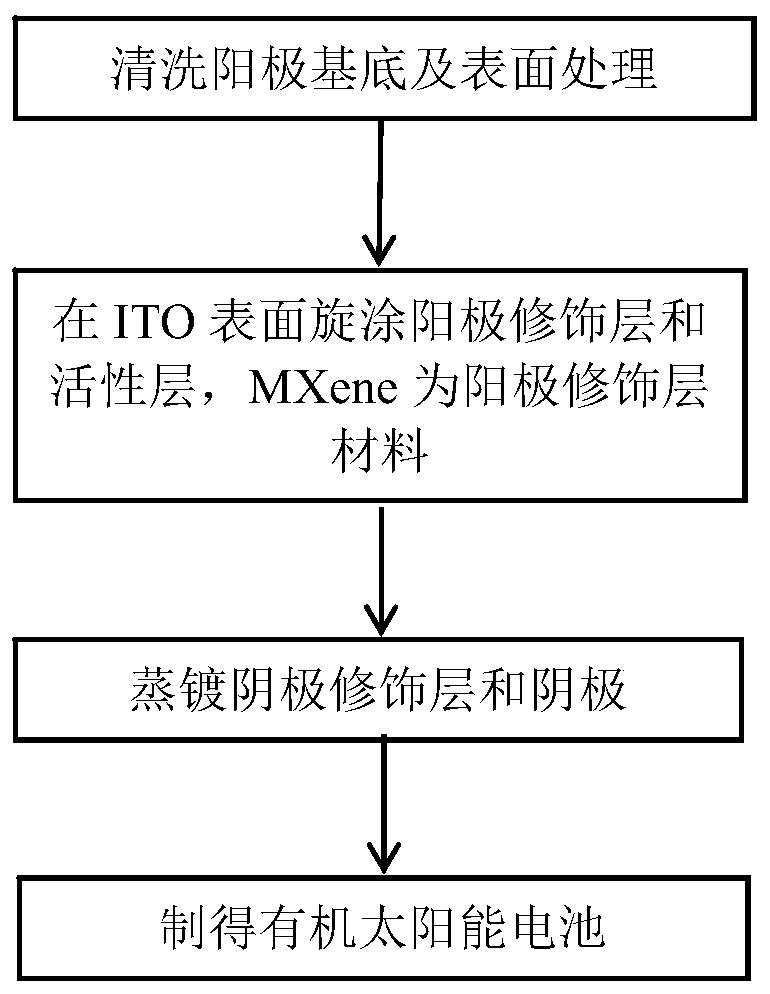

[0039] The preparation process of the above-mentioned organic solar cell is as follows:

[0040] Step 1. Ultrasonic cleaning with detergent, deionized water, acetone, absolute ethanol, and isopropanol for 20 minutes in sequence; then dry in a vacuum oven at 80°C.

[0041] Step 2, performing plasma surface treatment on the surface of the cleaned and dried anode substrate (ITO) for 5 minutes.

[0042] Step 3. Spin-coat the anode modification layer on the ITO surface treated in step 2; the preparation process of the anode modification layer is as follows: first, ultrasonically disperse the MXene aqueous solution, and filter it with a 0.22 μm organic filter element; secondly, prepare the above-mentioned MXene filtrate to a concentration of It is the solution of 0.2mg / ml; Finally, spin-coat the anode modification layer on the ...

Embodiment 2

[0055] The device structure of the organic solar cell in which MXene is used as the anode modification layer material in Example 2 is: ITO / MXene / P3HT:PCBM / Ca / Al.

[0056] The preparation process of the above-mentioned organic solar cell is as follows:

[0057] Step 1. Ultrasonic cleaning with detergent, deionized water, acetone, absolute ethanol, and isopropanol for 20 minutes in sequence; then dry in a vacuum oven at 80°C.

[0058] Step 2, performing plasma surface treatment on the surface of the cleaned and dried anode substrate (ITO) for 8 minutes.

[0059] Step 3. Spin-coat the anode modification layer on the ITO surface treated in step 2; the preparation process of the anode modification layer is as follows: first, ultrasonically disperse the MXene aqueous solution, and filter it with a 0.22 μm organic filter element; secondly, prepare the above-mentioned MXene filtrate to a concentration of 0.1mg / ml solution; finally spin-coat the anode modification layer on the anode s...

Embodiment 3

[0065] The device structure of the organic solar cell in which MXene is used as the anode modification layer material in Example 3 is: ITO / MXene / P3HT:PCBM / Ca / Al.

[0066] The preparation process of the above-mentioned organic solar cell is as follows:

[0067] Step 1. Ultrasonic cleaning with detergent, deionized water, acetone, absolute ethanol, and isopropanol for 20 minutes in sequence; then dry in a vacuum oven at 80°C.

[0068] Step 2, performing plasma surface treatment on the surface of the cleaned and dried anode substrate (ITO) for 10 minutes.

[0069] Step 3. Spin-coat the anode modification layer on the ITO surface treated in step 2; the preparation process of the anode modification layer is as follows: first, ultrasonically disperse the MXene aqueous solution, and filter it with a 0.22 μm organic filter element; secondly, prepare the above-mentioned MXene filtrate to a concentration of 0.15mg / ml solution; finally spin-coat the anode modification layer on the anode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com