Vacuum arc-extinguishing chamber with high heat dissipation

A vacuum interrupter, high heat dissipation technology, used in high-voltage air circuit breakers, contact heating/cooling, high-voltage/high-current switches, etc. Good speed and heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

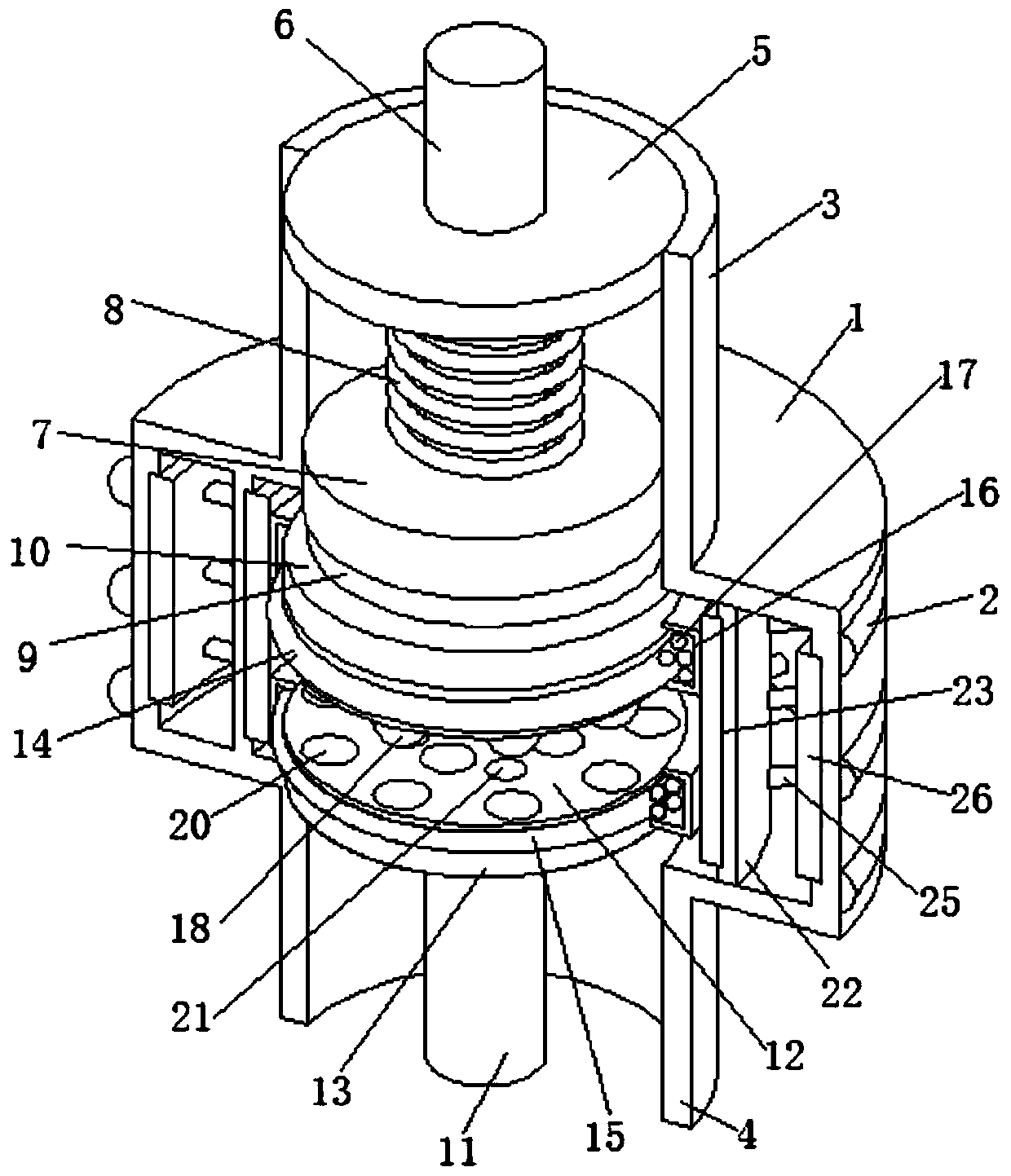

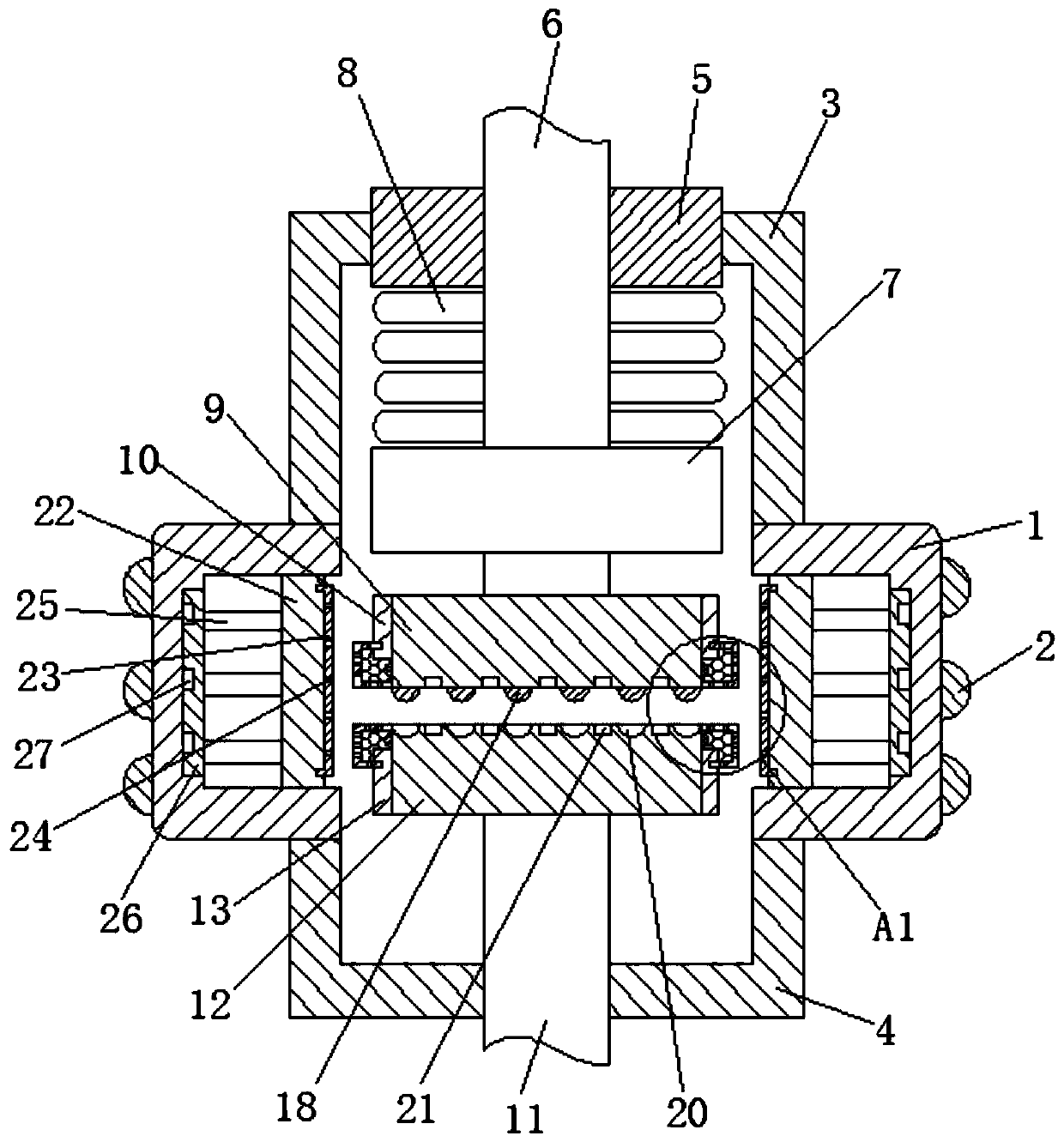

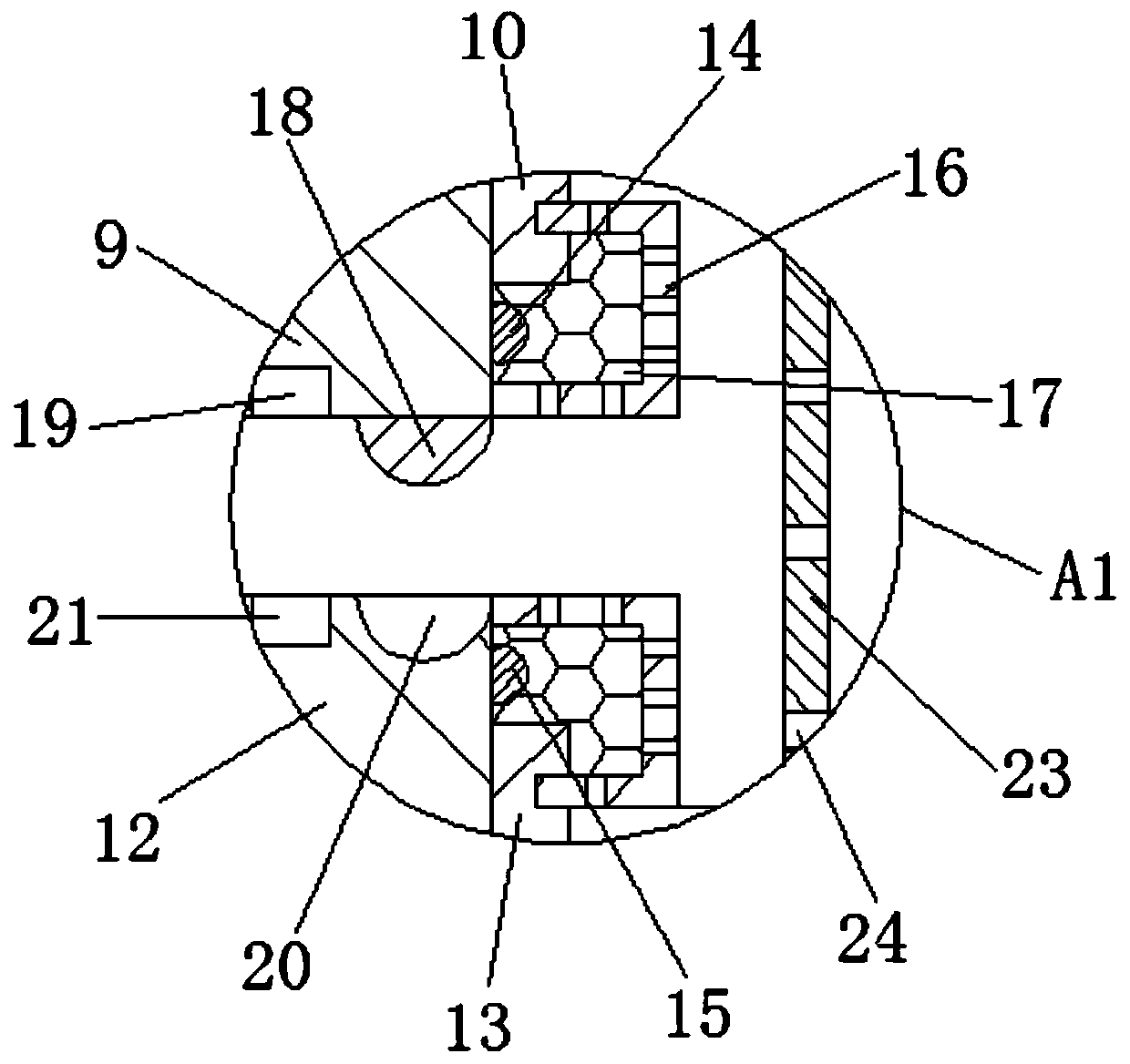

[0019] refer to Figure 1-3 , a vacuum interrupter with high heat dissipation, including an external leakage shielding cover 1, a plurality of first protrusions 2 are fixedly connected to the outer side of the external leakage shielding cover 1, and the function of the first protrusions 2 is to increase the external leakage The surface area of the shielding cover 1 in contact with the air speeds up the heat dissipation. The first protrusion 2 is integrated with the leakage shielding cover 1. The upper end of the leakage shielding cover 1 is fixedly connected with the first shell 3. The outer leakage shielding cover 1 The bottom end is fixedly connected with the sec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap