Temperature sensor capable of conversion fluorescent radiation and manufacturing method thereof

A technology of temperature sensor and manufacturing method, which is applied in the direction of physical/chemical change thermometers, thermometers, instruments, etc., to achieve good temperature sensing performance, compact structure, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technology, advantages and practical value of the present invention easy to understand, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

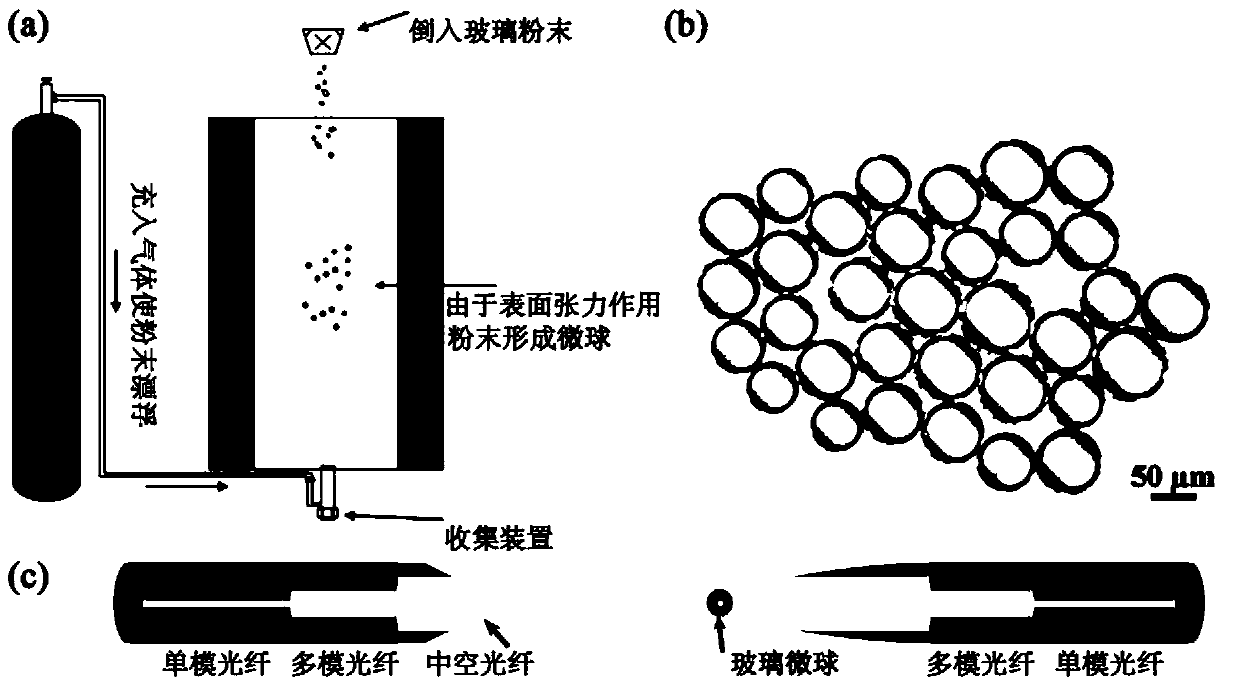

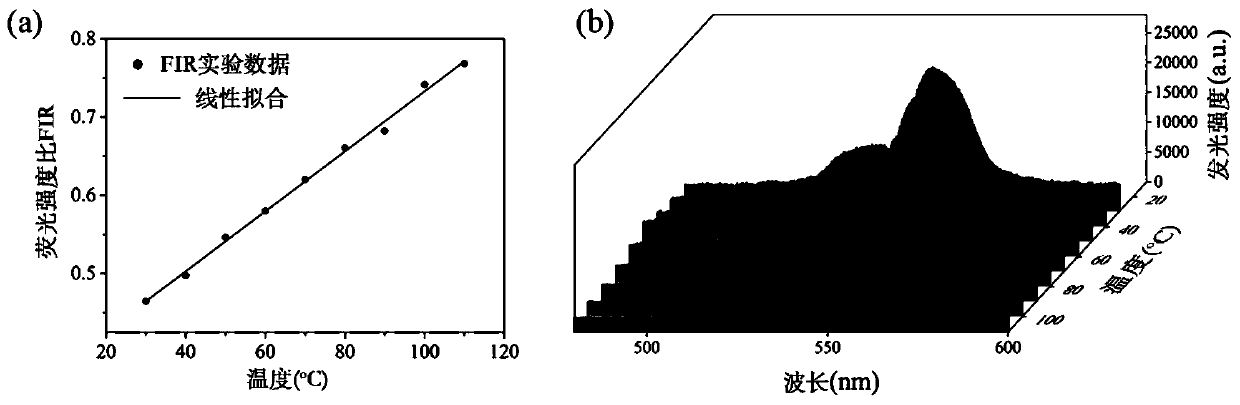

[0036] Such as figure 1 As shown in (c), the structure of the temperature sensor for converting fluorescent light in the present invention is single-mode optical fiber-multimode optical fiber-suspension three-core hollow special optical fiber-multimode optical fiber-single-mode optical fiber structure, specifically including single-mode optical fiber, multi-mode optical fiber, mode fiber, suspended three-core hollow special fiber, erbium-ytterbium co-doped tellurate glass microspheres; Pull the taper to form a tapered waist.

[0037] A method for manufacturing a temperature sensor that converts fluorescent luminescence specifically includes the following steps:

[0038] (1) Establish a theoretical model for coupling excitati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com