Experimental device and method for quickly closing upper corner to prevent gas leakage

An experimental device and gas technology, applied in the container discharge method, container filling method, equipment loaded into the pressure vessel, etc., can solve the lack of timeliness, rapidity and efficiency, gas disaster accidents, explosion gas leakage, etc. problems, to achieve the effect of reducing explosion damage, preventing gas leakage, and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

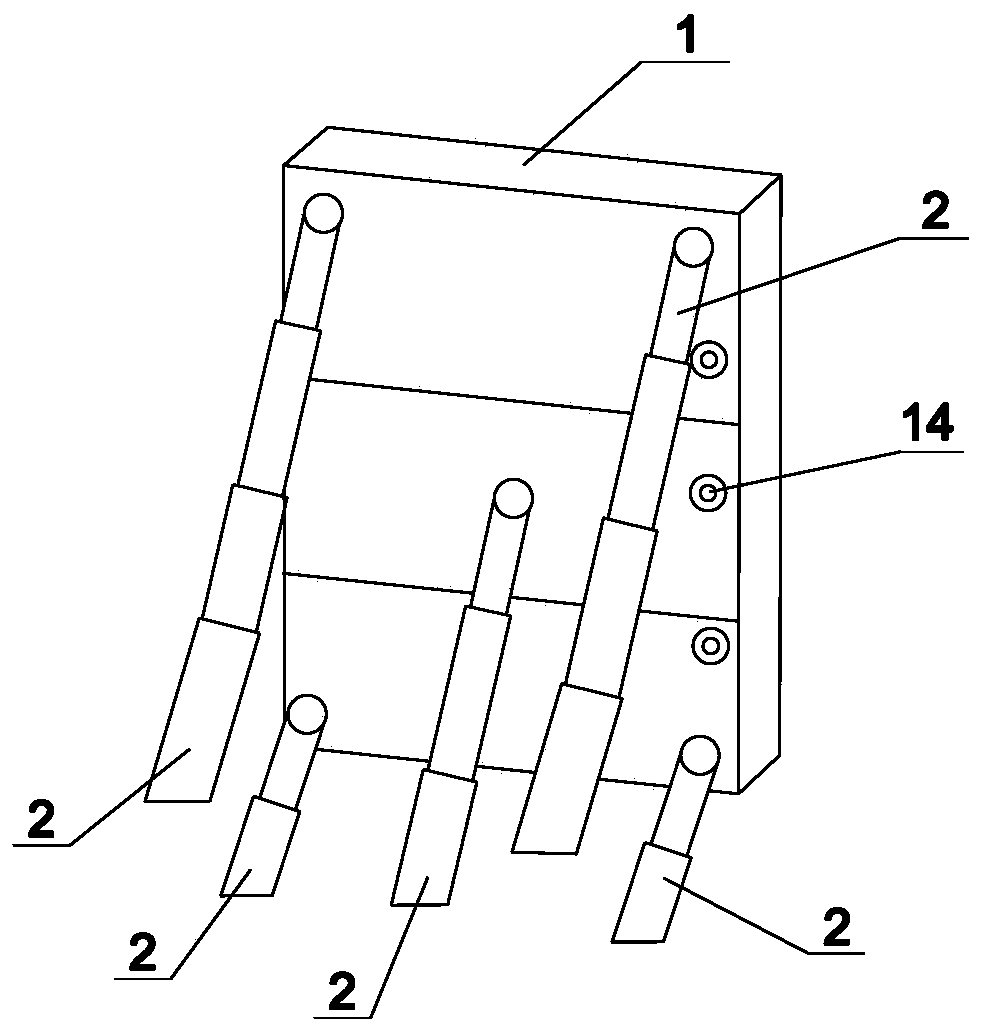

[0063] Such as figure 1 and figure 2 As shown, the experimental device for quickly closing the upper corner to prevent gas leakage of the present invention includes an air bag, an inflation system, a gas concentration detection system and a hydraulic support stabilization system;

[0064] The inner space of the airbag is divided into three parts, and an air hole 14 for connecting the inflation system is arranged on the airbag of each part;

[0065] The inflation system includes a high-pressure gas cylinder 11 equipped with methane gas, a gas delivery main pipe 8 connected to the outlet of the high-pressure gas cylinder 11 and three gas delivery sub-pipes 12 connected to the gas delivery main pipe 8, and the outlet of the high-pressure gas cylinder 11 On-off valve 10 is connected to it, and pressure gauge 7, control valve 4 and pressure gauge 5 are arranged on said gas transmission main pipe 8, and each said gas transmission branch pipe 12 is connected with decompression valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com