Modified ferrihydrite/hematite nano-rod core-shell structure compound light anode and application thereof

A technology of core-shell structure and hematite is applied in the field of modified ferrihydrite/hematite nanorod core-shell structure composite photoanode, which can solve the problem of fast photogenerated electron-hole recombination, short hole diffusion length, red Iron ore has problems such as poor conductivity, and achieves the effects of avoiding electrodeposition, excellent stability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

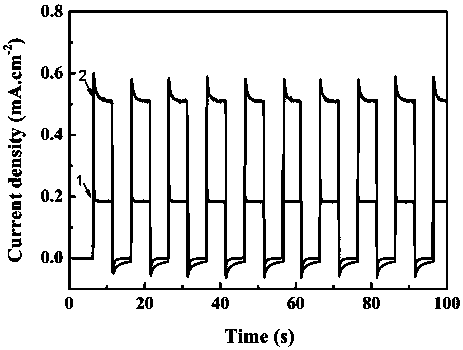

Image

Examples

Embodiment 1

[0033] A modified ferrihydrite / hematite nanorod core-shell structure composite photoanode is prepared by the following steps:

[0034] Step S1: Prepare 0.3M FeCl 3 ·6H 2 O and 2M NaNO 3 The aqueous solution is used as the growth solution of hematite (that is, the precursor solution); the conductive glass is used as the conductive substrate, and it is placed obliquely in a stainless steel reactor lined with polytetrafluoroethylene, with the conductive side facing down, and the precursor solution Pour it into the lining until it is full of 3 / 4 of the lining; put the reaction kettle in an oven, heat it at 100°C for 8 hours, then cool it down to room temperature naturally, synthesize a FeOOH film on conductive glass by solvothermal synthesis, and use deionized After washing with water, dry in the air for later use.

[0035] Step S2: Put the conductive glass with FeOOH film prepared in step S1 into a muffle furnace, raise the temperature to 550°C at a rate of 10°C / min, and keep ...

Embodiment 2

[0038] A modified ferrihydrite / hematite nanorod core-shell structure composite photoanode, the preparation process of which is the same as in Example 1, except that the growth solution of hematite in step S1 is 0.15M FeCl 3 ·6H 2 O and 1M NaNO 3 aqueous solution; the reaction temperature is 95°C, and the reaction time is 4h; after the temperature is raised to 550°C in step S2, the holding time is 30min.

Embodiment 3

[0040] A modified ferrihydrite / hematite nanorod core-shell structure composite photoanode, the preparation process of which is the same as in Example 1, the difference being that the growth solution of hematite in step S1 is 0.15M FeCl 3 ·6H 2 O and 1M NaNO 3aqueous solution; in step S2, after the temperature is raised to 800° C., the holding time is 20 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com