Preparation method of non-homogeneous layered-structure commercial pure titanium

A technology of industrial pure titanium and heterogeneous layer, which is applied in the field of preparation of industrial pure titanium with heterogeneous layered structure, can solve problems such as not being able to meet industrial production, and achieve improved comprehensive mechanical properties, simple process conditions, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] First of all, the present embodiment adopts the following equipment: Hot-rolling and cold-rolling multi-purpose rolling mill, tubular vacuum annealing furnace. The specific operation of preparing a kind of industrial pure titanium with heterogeneous layered structure in this embodiment is as follows:

[0028] (1) The commercially pure titanium plate used in this example has a thickness of 15mm, and its composition (wt.%) is as follows: 0.15O, 0.01N, 0.01C, 0.03Fe, and the rest is Ti and unavoidable impurities.

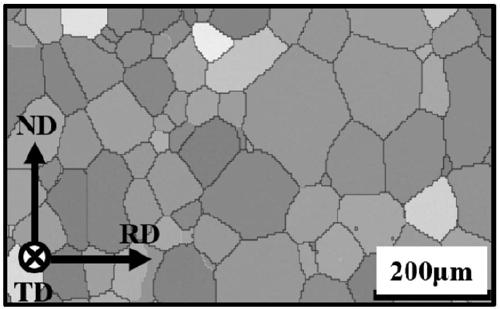

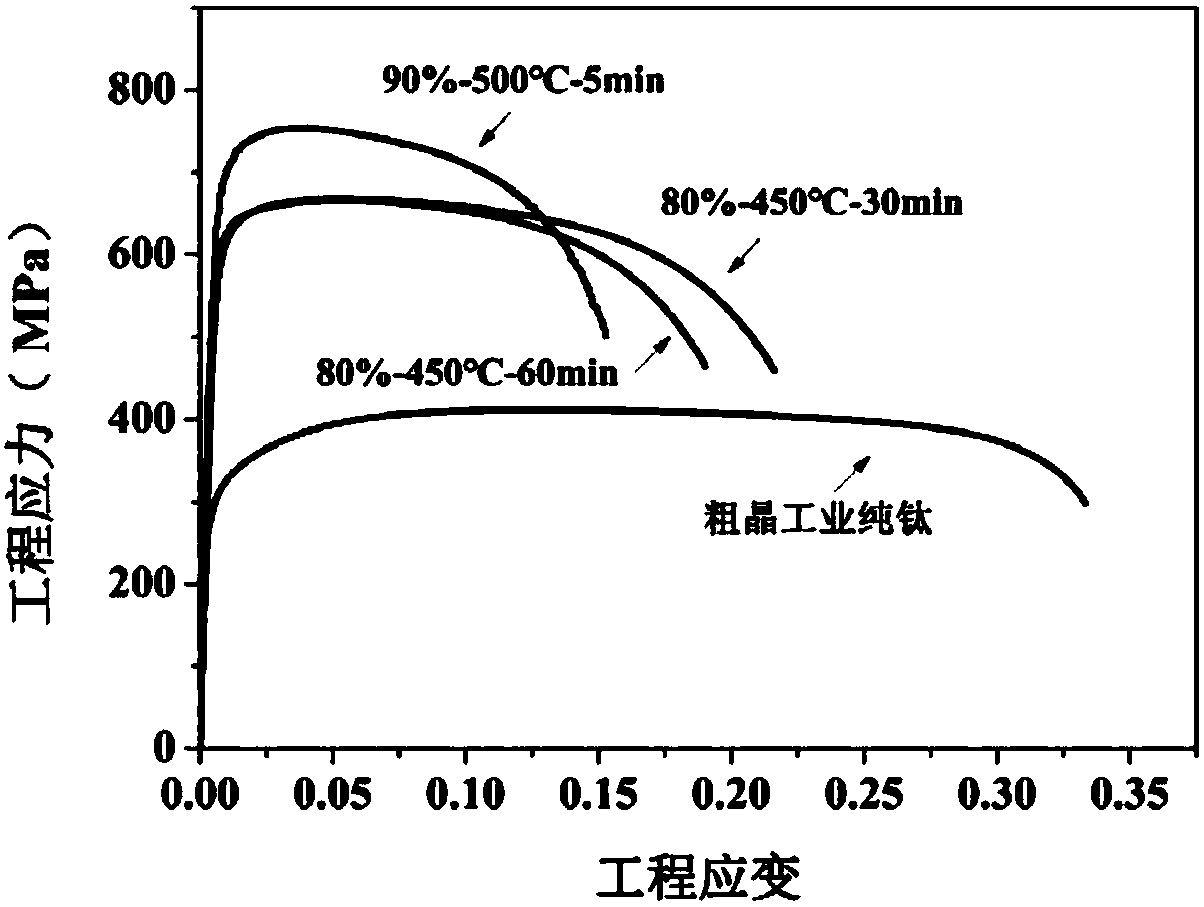

[0029] (2) The above-mentioned commercially pure titanium plate was kept in a tube-type vacuum annealing furnace at 750° C. for 2 hours to obtain a homogenized structure with an average grain size of 70 μm.

[0030] (3) The industrial pure titanium plate after homogenization annealing is cold-rolled at room temperature, the initial thickness is 15mm, the rolling reduction per pass is 0.3-0.5mm, and the plate thickness is finally rolled to 3mm , The total roll...

Embodiment 2

[0034] First of all, the present embodiment adopts the following equipment: Hot-rolling and cold-rolling multi-purpose rolling mill, tubular vacuum annealing furnace. The specific operation of preparing a kind of industrial pure titanium with heterogeneous layered structure in this embodiment is as follows:

[0035] (1) The commercially pure titanium plate used in this example has a thickness of 15mm, and its composition (wt.%) is as follows: 0.15O, 0.01N, 0.01C, 0.03Fe, and the rest is Ti and unavoidable impurities.

[0036] (2) The above-mentioned commercially pure titanium plate was kept in a tube-type vacuum annealing furnace at 750° C. for 2 hours to obtain a homogenized structure with an average grain size of 70 μm.

[0037] (3) The industrial pure titanium plate after homogenization annealing is cold-rolled at room temperature, the initial thickness is 15mm, the rolling reduction per pass is 0.3-0.5mm, and the plate thickness is finally rolled to 3mm , The total roll...

Embodiment 3

[0041] First of all, the present embodiment adopts the following equipment: Hot-rolling and cold-rolling multi-purpose rolling mill, tubular vacuum annealing furnace. The specific operation of preparing a kind of industrial pure titanium with heterogeneous layered structure in this embodiment is as follows:

[0042] (1) The commercially pure titanium plate used in this example has a thickness of 10mm, and its composition (wt.%) is as follows: 0.15O, 0.01N, 0.01C, 0.03Fe, and the rest is Ti and unavoidable impurities.

[0043] (2) The above-mentioned commercially pure titanium plate was kept in a tube-type vacuum annealing furnace at 750° C. for 2 hours to obtain a homogenized structure with an average grain size of 70 μm.

[0044] (3) The industrial pure titanium plate after homogenization annealing is cold-rolled at room temperature, the initial thickness is 10mm, the rolling reduction per pass is 0.3-0.5mm, and the final plate thickness is rolled to 1mm , The total rollin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com