Technique for purifying and enriching Au and Ag from noble metal alloy

A technology for purifying and enriching precious metals, which is applied in the directions of non-metallic elements, improvement of process efficiency, selenium/tellurium compounds, etc., can solve the problems of increased production cost and low direct yield of gold and silver, and achieves high direct yield and separation. Good effect, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the examples, but the present invention is not limited in any way, and any transformation made based on the teaching of the present invention falls within the protection scope of the present invention.

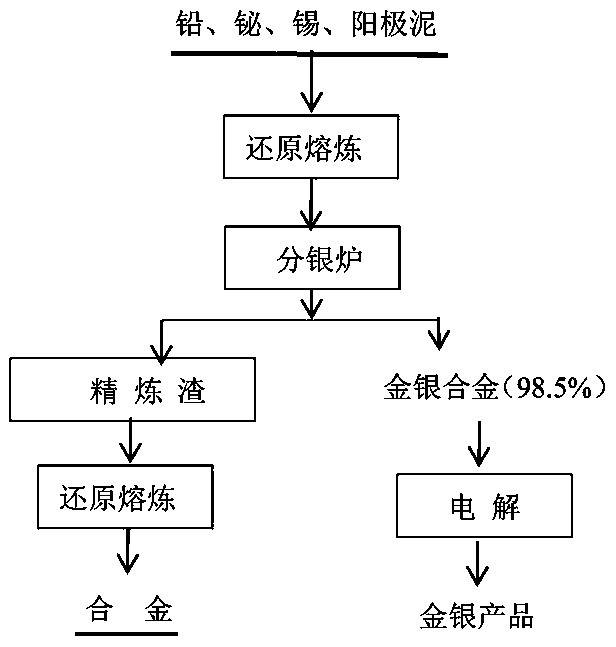

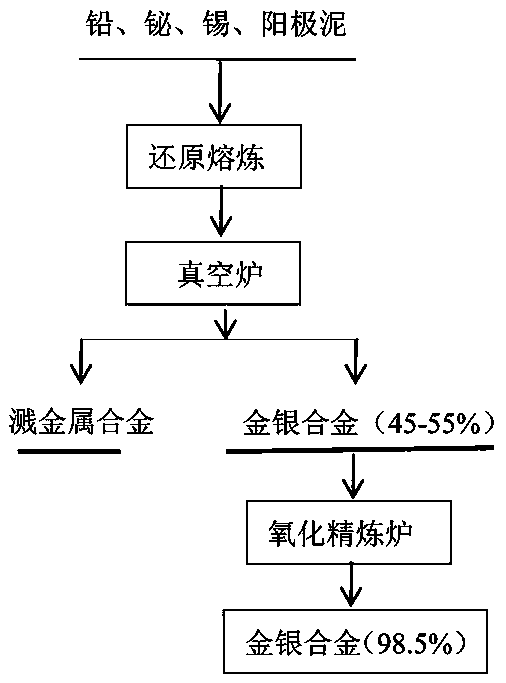

[0029] Reference attached figure 2 A precious metal alloy purification and enrichment gold and silver process, oxidation refining process:

[0030] The crude gold-silver alloy with a content of 45-55% obtained after vacuum furnace separation is placed in the hearth, and the temperature is controlled at 950°C-1100°C for oxidation and refining. At this time, the molten lead contacts with the oxygen in the air to become lead oxide. Due to the effect of surface tension, most of the PbO is absorbed by the porous hearth, and a small part is volatilized, and the gold and silver are not oxidized, and remain in the hearth in granular form. According to metallurgy, the oxidation smelting process higher th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com