Coal cracking environmentally friendly cycle power generation system for preparing small particle coal

A cyclic power generation and environmental protection technology, which is applied in special forms of dry distillation, petroleum industry, gas purification of condensed non-gaseous materials, etc., can solve problems such as inability to make full use of coal oil and gas resources, and achieve the effect of improving comprehensive utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

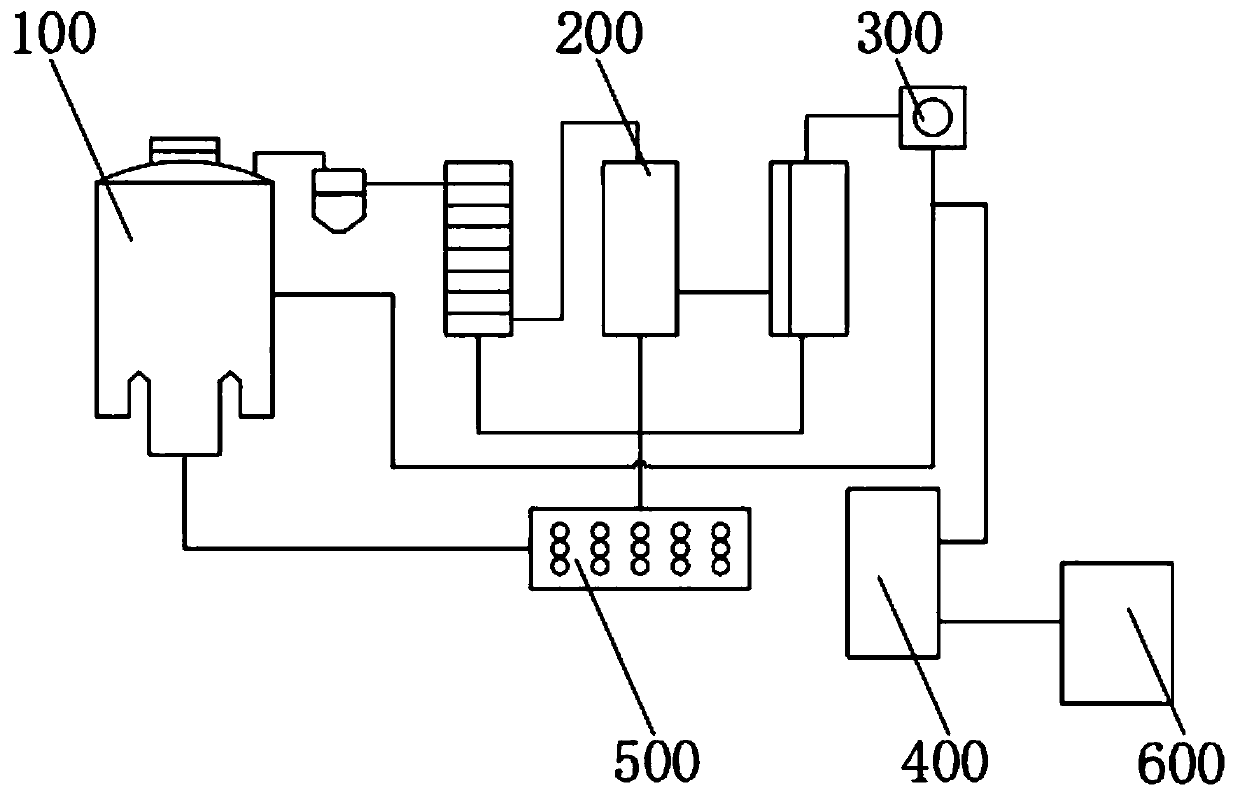

[0041] Please refer to figure 1 , an environment-friendly cyclic power generation system for small particle size coal preparation by briquette cracking and cracking, comprising: cracking furnace 100, multi-stage purification equipment 200, flow diversion device 300, power plant 400, sewage treatment device 500 and control machine room 600; the cracking furnace 100 passes The pipeline is connected to the multi-stage purification equipment 200, the multi-stage purification equipment 200 is connected to the flow splitting device 300 through a pipeline, the flow split device 300 is connected to the cracking furnace 100 and the power plant 400 through a pipeline, the The interior of the power plant 400 is provided with a tail gas treatment device 700, the power plant 400 is connected to the control room 600 through wires, the multi-stage purification equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com