Stamp rubber material capable of being used for capacitor printing and preparation method thereof

A rubber and seal technology, applied in the field of rubber stamp rubber and its preparation, can solve the problems of thermal instability, poor dimensional stability of rubber, adhesion, wear resistance and corrosion resistance, etc., to achieve adhesion Strong, good mechanical strength, excellent dimensional stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

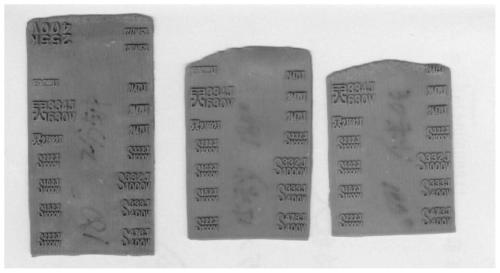

Image

Examples

preparation example Construction

[0042] Preferably, the preparation method of described modified nanometer calcium carbonate comprises the steps:

[0043] 10 parts by weight of nano-calcium carbonate and 1 to 2 parts by weight of functionalized hyperbranched polyethylene are added to a high-speed mixer, stirred and mixed for 45 minutes at 70°C, then heated to 210°C, and (0.5 to 1.5 parts by weight part) polyphosphoric acid solution of vinyl silsesquioxane (CAS: 69655-76-1, purchased from Suzhou Sisuo New Material Co., Ltd.) and 0.004 to 0.008 parts by weight of initiator were added to the above mixing system, and the heat preservation reaction After 3 to 5 hours, the system is cooled to room temperature, poured into acetone solution, washed, filtered, and dried.

[0044] Preferably, the functionalized hyperbranched polyethylene is maleic anhydride graft modified hyperbranched polyethylene.

[0045] Preferably, the graft ratio of the maleic anhydride graft modified hyperbranched polyethylene is 5-12%.

[004...

Embodiment 1

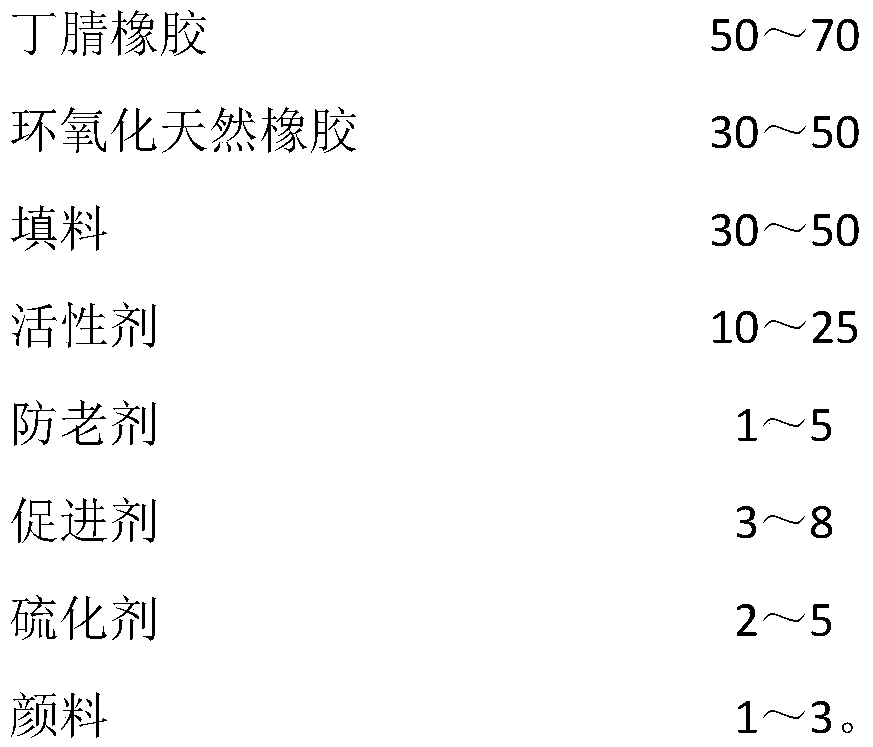

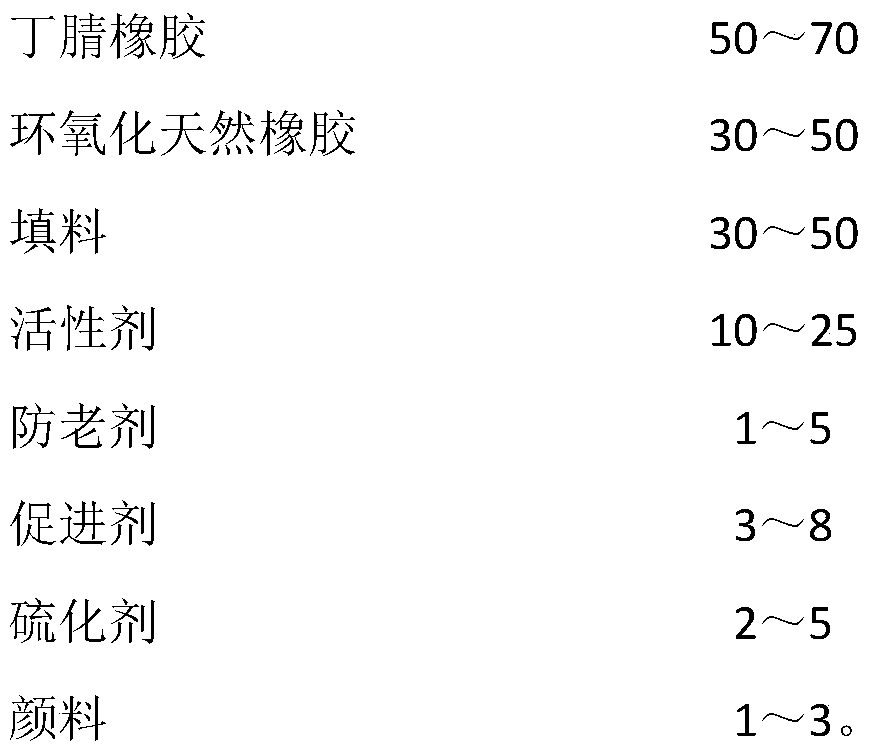

[0083] Embodiment 1 provides a kind of stamp glue, and its preparation raw material, by weight, comprises the following components:

[0084]

[0085] The nitrile rubber is the product of N-726 (the acrylonitrile content is 27% and the Mooney viscosity (ML100 ℃ 1+4) is 60) for the trade mark of Sai Kede Rubber and Plastics Group Company; the epoxidized natural rubber is made of tropical Provided by the Rubber Research Institute of the Academy of Sciences, the degree of cyclization is 5%; the filler is composed of 30 parts by weight of white carbon black and 10 parts by weight of calcium carbonate, and the white carbon black is precipitated white carbon black, purchased from Jinan Jinri and Chemical Co., Ltd., the nano-calcium carbonate is purchased from Beijing Deke Daojin Technology Co., Ltd., and its average particle diameter is 20nm; the active agent is made up of 1 weight part of stearic acid and 10 weight parts of zinc oxide; The anti-aging agent is composed of anti-agi...

Embodiment 2

[0091] Embodiment 2 provides a kind of stamp glue, and its preparation raw material, by weight, comprises the following components:

[0092] Nitrile rubber 70

[0093] Epoxidized Natural Rubber 50

[0094] Filler 50

[0095] active agent 25

[0096] Antiager 5

[0097] Accelerator 8

[0098] Vulcanizing agent 5

[0099] Pigment 3.

[0100] The nitrile rubber is the product of N-608 (the acrylonitrile content is 33% and the Mooney viscosity (ML100° C. 1+4) is 80) of Sai Kede Rubber and Plastic Group Company; Provided by the Rubber Research Institute of the Academy of Sciences, the degree of cyclization is 60%; the filler is composed of 50 parts by weight of white carbon black and 30 parts by weight of calcium carbonate, and the white carbon black is precipitated white carbon black, purchased from Jinan Jinri and Chemical Co., Ltd., the nano-calcium carbonate is purchased from Beijing Deke Daojin Technology Co., Ltd., and its average particle diameter is 20nm; the active ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Grafting rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com