Preparation method of degradable high-performance water absorbent resin

A water-absorbent resin, high-performance technology, applied in the field of high water-absorbent degradable resin and its preparation, can solve the problems of difficulty in large-scale application, low water absorption rate and low water absorption rate of water-absorbent resin, and achieves easy large-scale industrial application. Production, good bioabsorbability, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

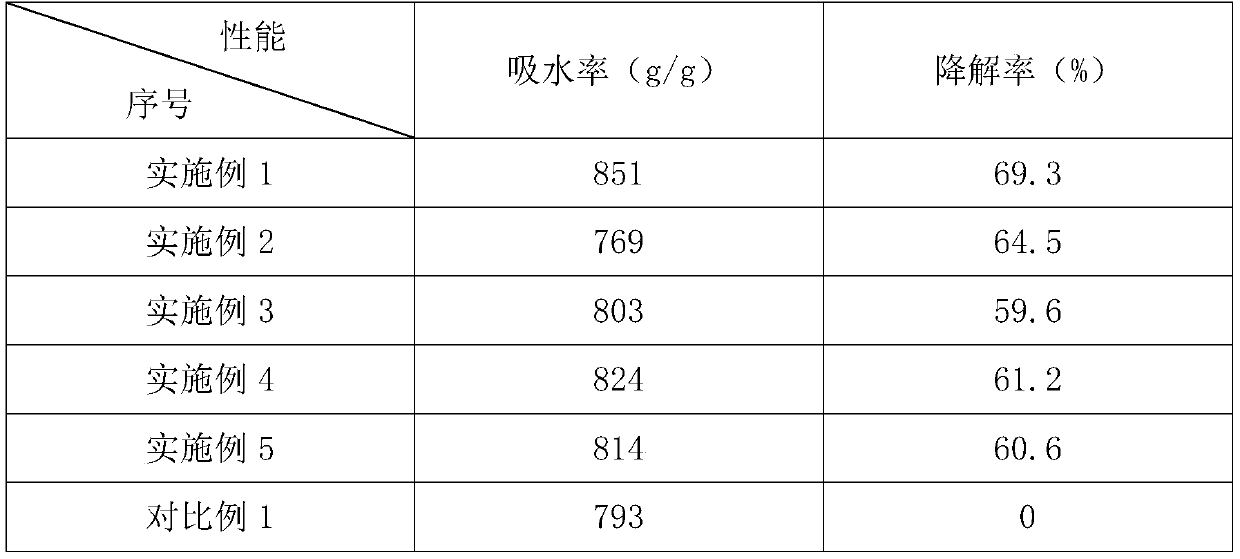

Examples

Embodiment 1

[0024] A kind of preparation method of degradable high-performance water-absorbing resin provided by the embodiment of the present invention 1 comprises the following steps:

[0025] S1: Weigh a certain amount of polybutylene succinate, and pulverize the polybutylene succinate for later use;

[0026] S2: Weigh a certain amount of polybutylene succinate powder and acrylic acid according to the mass ratio of polybutylene succinate and acrylic acid as 1:6, and add them to a four-necked flask respectively;

[0027] S3: Prepare an aqueous sodium hydroxide solution with a concentration of 25%, add the aqueous sodium hydroxide solution into a four-necked flask to neutralize acrylic acid, control the neutralization degree of acrylic acid to 70%, and obtain a solution of acrylic acid and sodium acrylate;

[0028] S4: After cooling the temperature in the four-neck flask to room temperature, slowly add an initiator of 0.2% of acrylic acid mass and a crosslinking agent of 0.7% of acrylic ...

Embodiment 2

[0036] A kind of preparation method of degradable high-performance water-absorbing resin provided by the embodiment of the present invention 2 comprises the following steps:

[0037] S1: Weigh a certain amount of polybutylene succinate, and pulverize the polybutylene succinate for later use;

[0038] S2: Weigh a certain amount of polybutylene succinate powder and acrylic acid according to the mass ratio of polybutylene succinate and acrylic acid as 1:6, and add them to a four-necked flask respectively;

[0039] S3: Prepare an aqueous sodium hydroxide solution with a concentration of 25%, add the aqueous sodium hydroxide solution into a four-necked flask to neutralize acrylic acid, control the neutralization degree of acrylic acid to 80%, and obtain a solution of acrylic acid and sodium acrylate;

[0040] S4: After cooling the temperature in the four-neck flask to room temperature, slowly add an initiator of 0.2% of acrylic acid mass and a crosslinking agent of 0.7% of acrylic ...

Embodiment 3

[0048] The preparation method of a kind of degradable high-performance water-absorbing resin provided by embodiment 3 of the present invention comprises the following steps:

[0049] S1: Weigh a certain amount of polybutylene succinate, and pulverize the polybutylene succinate for later use;

[0050] S2: Weigh a certain amount of polybutylene succinate powder and acrylic acid according to the mass ratio of polybutylene succinate and acrylic acid as 1:6, and add them to a four-necked flask respectively;

[0051] S3: Prepare an aqueous sodium hydroxide solution with a concentration of 25%, add the aqueous sodium hydroxide solution into a four-necked flask to neutralize acrylic acid, control the neutralization degree of acrylic acid to 70%, and obtain a solution of acrylic acid and sodium acrylate;

[0052] S4: After cooling the temperature in the four-neck flask to room temperature, slowly add an initiator of 0.5% of acrylic acid mass and a crosslinking agent of 0.7% of acrylic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com