Treatment process for removing total organic carbon and organic halides in biochemical effluents

An organic halide, biochemical water effluent technology, applied in the field of water treatment, to achieve good social and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

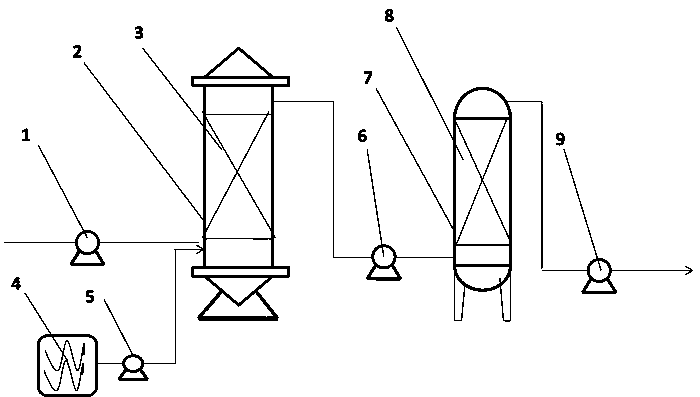

[0018] A treatment system for simultaneously removing total organic carbon and organic halides in biochemical effluent water, water inlet pump, fixed bed oxidation reaction tank, modified diatomaceous earth-ferrous sulfate filler, hydrogen peroxide dosing tank, dosing pump, lift pump, Modified activated carbon adsorption tower, modified activated carbon, drainage pump.

[0019] The biochemical effluent is industrial wastewater treated by a biochemical pool. The characteristics of the biochemical effluent quality: pH is 7.9, total organic carbon is 62.9 mg / L, and organic halide is 10.8 mg / L.

[0020] The biochemical effluent is poured into the fixed bed oxidation reaction tank from the bottom through the water inlet pump, and the modified diatomite-ferrous sulfate filler is placed in the fixed bed oxidation reaction tank, and the modified diatomite-ferrous sulfate filler accounts for the entire fixed bed oxidation reaction tank. 95% of the volume of the reaction tank. The res...

Embodiment 2

[0028]A treatment system for simultaneously removing total organic carbon and organic halides in biochemical effluent water, water inlet pump, fixed bed oxidation reaction tank, modified diatomaceous earth-ferrous sulfate filler, hydrogen peroxide dosing tank, dosing pump, lift pump, Modified activated carbon adsorption tower, modified activated carbon, drainage pump.

[0029] The biochemical effluent is industrial wastewater treated by a biochemical pool. The characteristics of biochemical effluent quality: pH is 8.7, total organic carbon is 25.9 mg / L, and organic halide is 8.9 mg / L.

[0030] The biochemical effluent is poured into the fixed bed oxidation reaction tank from the bottom through the water inlet pump, and the modified diatomite-ferrous sulfate filler is placed in the fixed bed oxidation reaction tank, and the modified diatomite-ferrous sulfate filler accounts for the entire fixed bed oxidation reaction tank. 85% of the volume of the reaction tank. The residence...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com