A rolling ball multifunctional conveying device and its control method

A multi-functional conveying and control method technology, applied in the direction of conveyor control devices, conveyors, mechanical conveyors, etc., can solve the problems of inability to realize real-time control and precise control, low degree of automation, etc., achieve high degree of freedom and low maintenance cost Low, universal compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

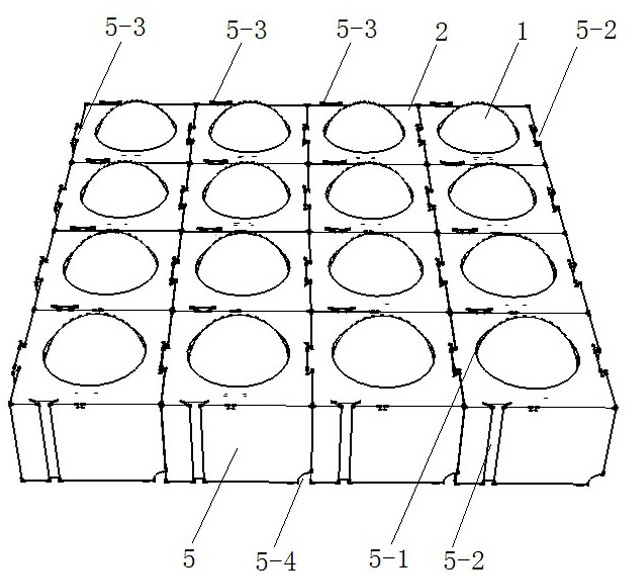

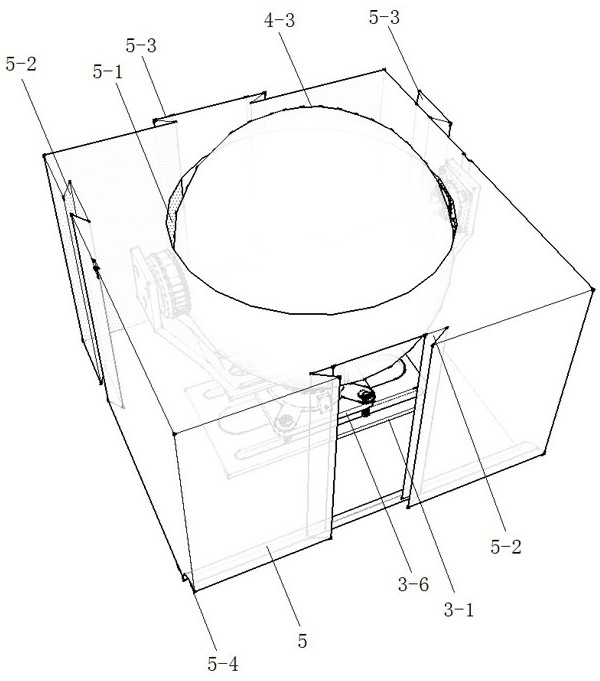

[0025] Embodiment 1, a kind of rolling ball type multifunctional conveying device, such as figure 1 As shown, several driving units 1 are included, and several driving units 1 are assembled to form a rectangular conveying platform 2. Different combination forms can be selected according to the conveying requirements of different materials, and conveying platforms of different shapes can be combined.

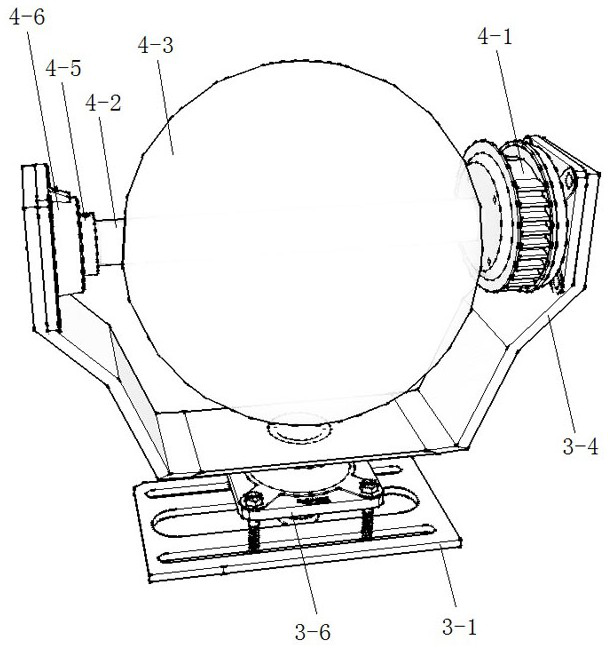

[0026] Such as image 3 As shown, each driving unit 1 includes a steering mechanism and a rolling mechanism, the rolling mechanism is used to drive the material to run, and the steering mechanism is used to change the conveying direction of the material. The steering mechanism includes a base 3-1, the base 3-1 is provided with a stepping motor 3-3 with a drive shaft 3-2 arranged vertically, and the drive shaft 3-2 of the step motor 3-3 is fixedly connected with a rotating bracket 3-4, the stepping motor 3-3 can drive the rotating bracket 3-4 to rotate 360°, so as to realize the ...

Embodiment 2

[0032] Embodiment 2, a rolling ball type multifunctional conveying device, the housing 5 is provided with a wiring channel 5-4 for routing the drive circuit, the setting of the wiring channel 5-4 can not only effectively prevent the circuit from being damaged, Moreover, the regularity of wiring is effectively improved, and maintenance and replacement are facilitated.

[0033] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0034] Embodiment 3, a rolling ball type multifunctional conveying device, the bottom of the base is provided with a pressure sensor connected to the industrial computer, and the industrial computer controls the stepping motor 3-3 and the long-axis motor through the real-time data detected by the pressure sensor 4-1 rotation, the industrial computer is also connected with an alarm. The industrial computer can monitor the conveying status of the material in real time according to the data detected by the pressure sensor. When the detected data is abnormal, the industrial computer can control the alarm to alarm, which is convenient for the maintenance personnel to replace the failed drive unit in time.

[0035] Other structures of this embodiment are the same as Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com