Vehicle thermal management system and vehicle

A thermal management system and vehicle technology, applied in the field of electric vehicles, can solve the problems of battery pack temperature discharge efficiency reduction, heating efficiency and heating effect to be improved, and low efficiency of electric heaters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

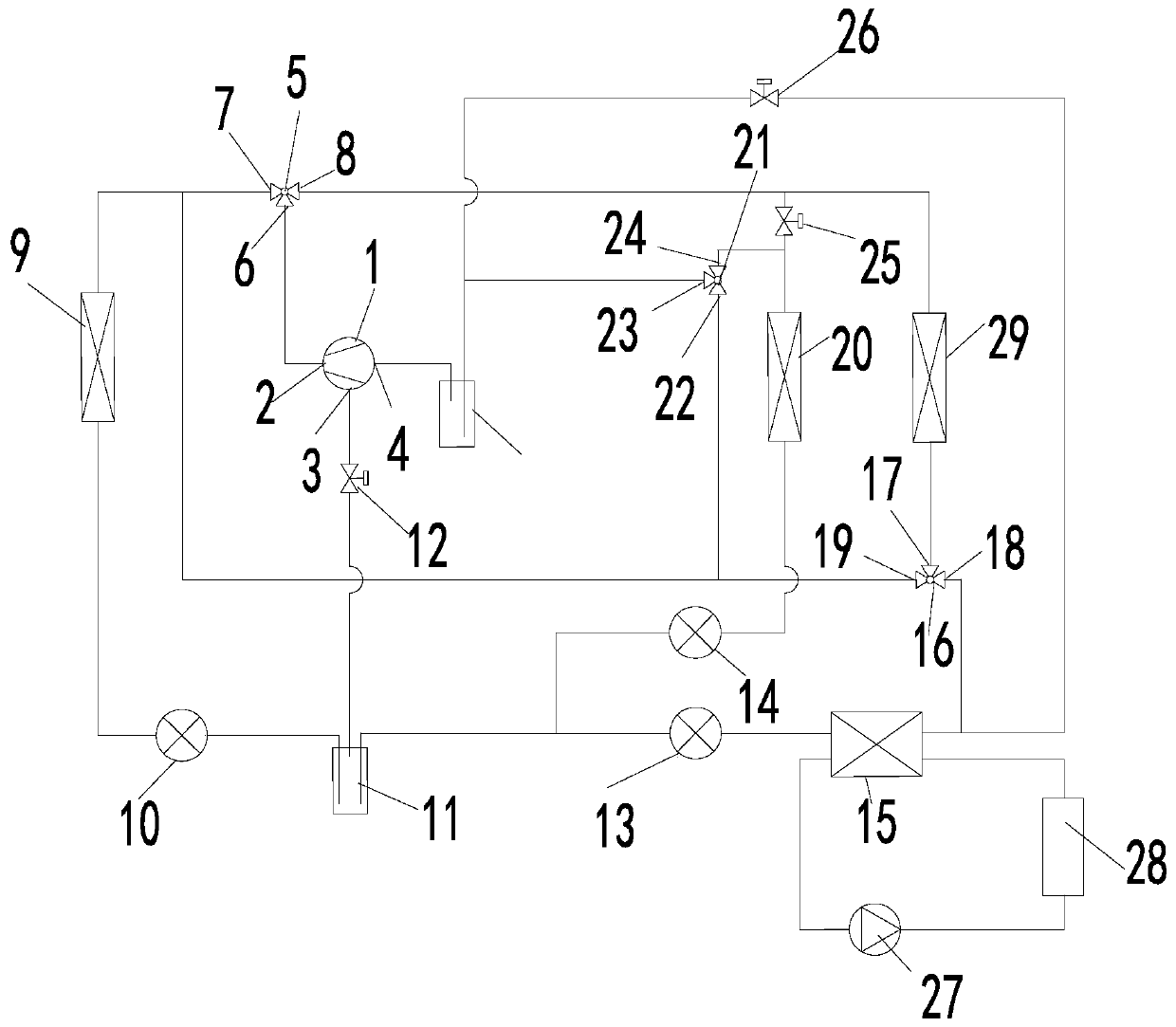

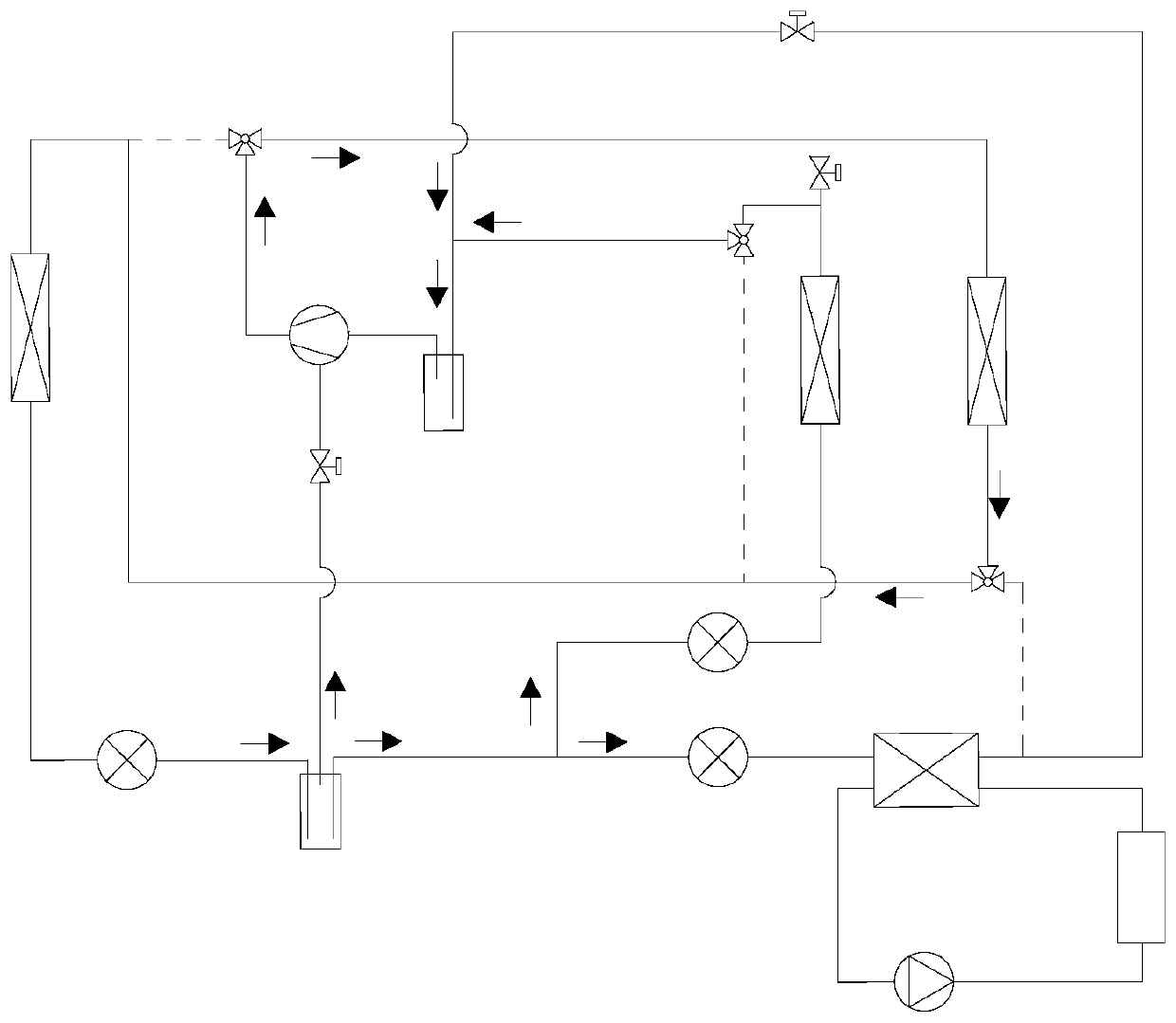

[0044] like figure 1As shown, the present invention provides a vehicle thermal management system, including a power component temperature regulation subsystem and an air conditioning subsystem; the air conditioning subsystem includes an in-vehicle heat exchange group and a first heat exchanger 15; the in-vehicle heat exchange The group and the first heat exchanger 15 are connected in parallel or in series; the power component temperature regulation subsystem and the air conditioning subsystem are connected and exchanged through the first heat exchanger 15 .

[0045] The first heat exchanger 15 is connected in parallel or in series with the in-vehicle heat exchange group. The heat exchange agent in the air-conditioning subsystem that flows to the in-vehicle heat exchange group is divided into a part and flows through the first heat exchanger 15 or all of it flows through the first heat exchanger. and the air conditioning subsystem and the power component temperature regulation ...

Embodiment 2

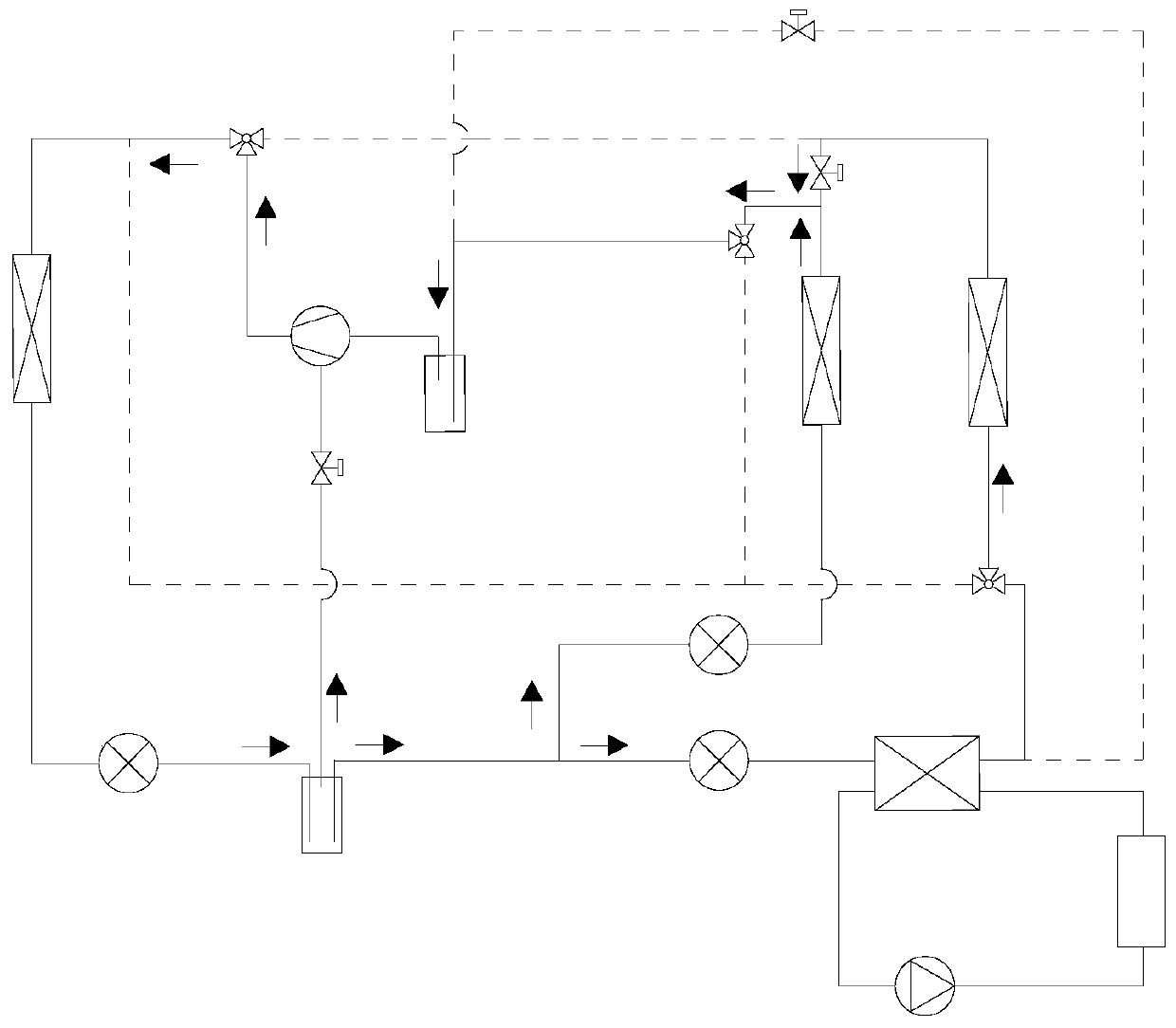

[0075] This embodiment is basically the same as Embodiment 1, and the difference lies in:

[0076] The in-vehicle heat exchange group includes a fourth heat exchanger; the third port of the flasher 11 is communicated with one end of the fourth throttle device and one end of the fifth throttle device respectively, and the fourth throttle device The other end of the fourth heat exchanger communicates with one end of the fourth heat exchanger, the other end of the fifth throttle device communicates with one end of the first heat exchanger 15, and the other end of the fourth heat exchanger communicates with the other end of the fourth heat exchanger. The other end of the first heat exchanger 15 is respectively communicated with one end of the first branch pipe, and the other end of the first branch pipe is respectively communicated with the third interface 8 and the inlet of the gas-liquid separator, One end of the off-vehicle heat exchanger 9 is also communicated with the inlet o...

Embodiment 3

[0082] Based on the same inventive idea, the present invention also provides a vehicle, including the vehicle thermal management system.

[0083] The on-off element in the above three embodiments can be selected as a solenoid valve, the throttle device in the above three embodiments can be selected as a throttle valve; the first heat exchanger in the above three embodiments can be selected from a plate heat exchanger.

[0084] It should be noted that, in this document, relational terms such as "first" and "second" etc. are only used to distinguish one entity or operation from another entity or operation, and do not necessarily require or imply these There is no such actual relationship or sequence between entities or operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com