A method for continuous preparation of copper-based amorphous thin strip

A thin strip, amorphous technology, applied in the field of amorphous alloy preparation, can solve the problem that no specific process protection node and technical implementation plan, smelting temperature, heat preservation measures cooling rate, casting and rolling force and other detailed parameters are not disclosed. , to achieve the effect of small deformation, good heat conduction under pressure, and large cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

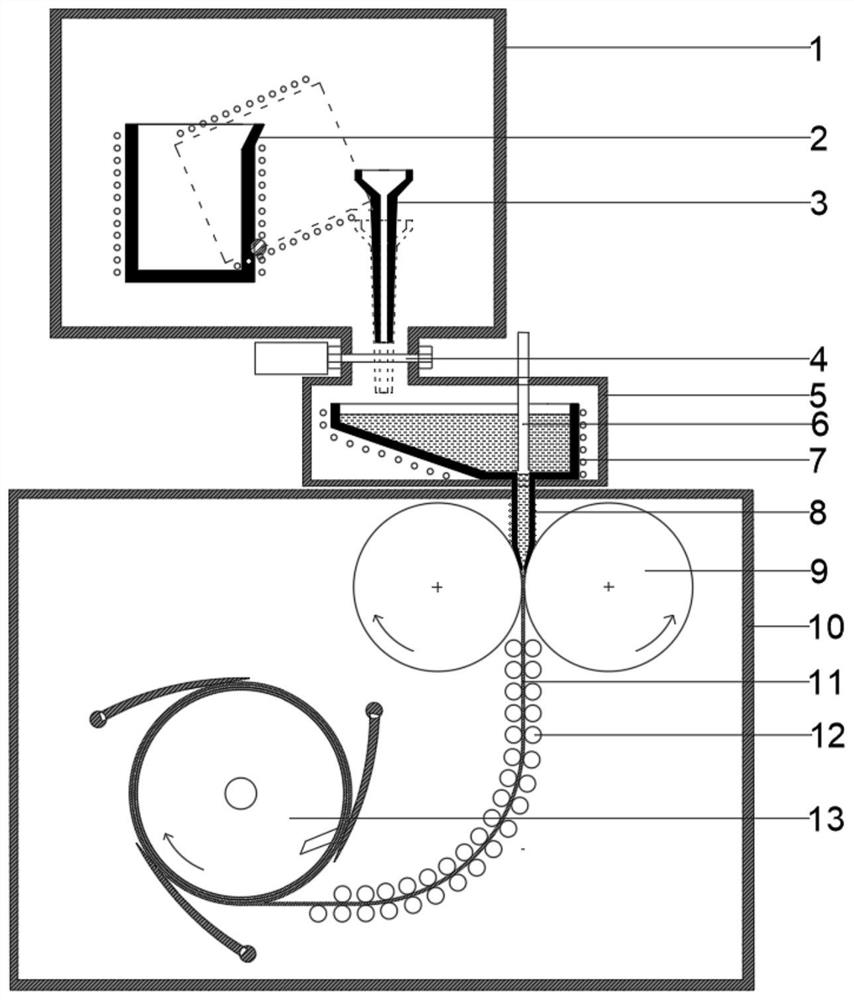

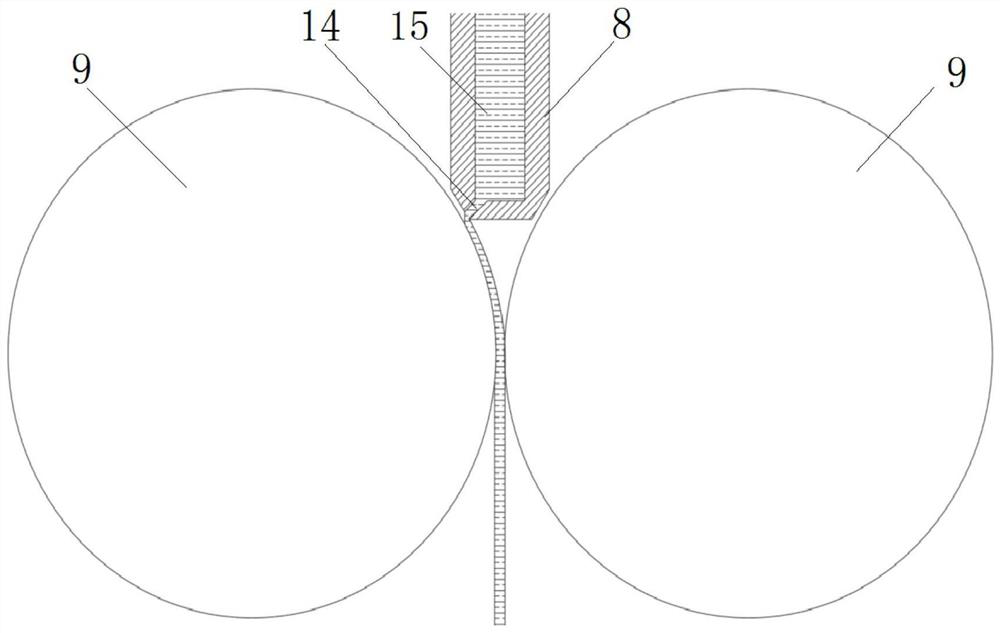

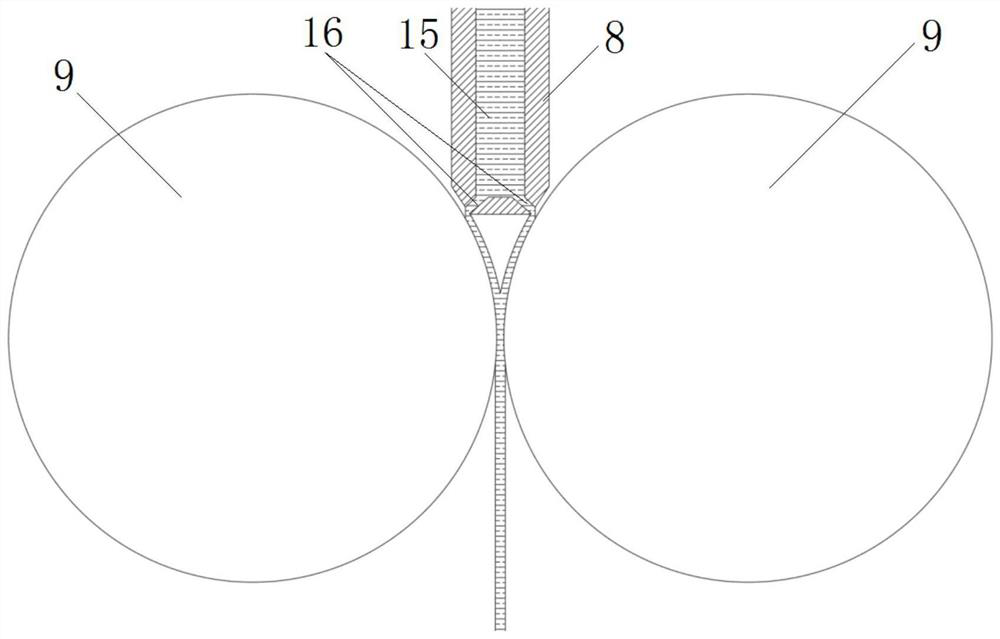

Method used

Image

Examples

Embodiment 1

[0038] Alloy composition: (Cu 60 Zr 20 f 10 Ti 10 ) 99.9 o 0.1 (atomic percentage at.%, the same below);

[0039] Distribution method: deep into the roll gap;

[0040] Preparation process:

[0041] a. Prepare 20kg of raw material according to the atomic percentage, put it into a vacuum induction melting furnace, and evacuate it to 0.05Pa, heat the alloy raw material until it is completely melted, and continue melting at 1500°C for 10 minutes.

[0042] b. Turn off the vacuum pump, fill the vacuum induction melting furnace with high-purity argon with a volume purity of 99.999% to atmospheric pressure, open the gate valve, put down the guide tube, and pass the alloy through the guide tube (the preheating temperature of the guide tube 920°C) into the tundish protected by high-purity argon.

[0043] c. After the alloy is soaked in the tundish, open the stopper, and evenly distribute the alloy melt through the distribution nozzle (the preheating temperature of the distributi...

Embodiment 2

[0048] Alloy composition: (Cu 46 Zr 42 Al 7 Y 5 ) 99.9 o 0.1 ;

[0049] Distribution method: deep into the roll gap;

[0050] Preparation process:

[0051] a. Prepare 20kg of raw materials according to the atomic percentage, put them into a vacuum induction melting furnace, and evacuate to 0.03Pa, heat the alloy raw materials until they are completely melted, and continue melting at 1400°C for 20 minutes.

[0052] b. Turn off the vacuum pump, fill the vacuum induction melting furnace with high-purity argon with a volume purity of 99.999% to atmospheric pressure, open the gate valve, put down the guide tube, and pass the alloy through the guide tube (the preheating temperature of the guide tube 900°C) into the tundish protected by high-purity argon.

[0053] c. After the alloy is soaked in the tundish, open the stopper, and evenly distribute the alloy melt through the distribution nozzle (the preheating temperature of the distribution nozzle is 1100°C) into the gap of t...

Embodiment 3

[0058] Alloy composition: (Cu 60 Zr 20 f 10 Ti 10 ) 99.9 o 0.1 ;

[0059] Distribution method: deep into the roll gap;

[0060] Preparation process:

[0061] a. Prepare 20kg of raw materials according to the atomic percentage, put them into a vacuum induction melting furnace, and evacuate to 0.08Pa, heat the alloy raw materials until they are completely melted, and continue melting at 1500°C for 10 minutes.

[0062] b. Turn off the vacuum pump, fill the vacuum induction melting furnace with 99.999% high-purity argon to atmospheric pressure, open the gate valve, put down the guide tube, and pass the alloy through the guide tube (the preheating temperature of the guide tube is 900 ℃) into the tundish protected by high-purity argon.

[0063] c. After the alloy is soaked in the tundish, open the stopper, and evenly distribute the alloy melt through the distribution nozzle (the preheating temperature of the distribution nozzle is 1150°C) into the gap of the casting roll, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com