Method and system for removing nitrogen oxides from low-temperature flue gas

A low-temperature flue gas and nitrogen oxide technology, applied in the fields of environmental protection and flue gas purification, can solve problems such as high energy consumption, complex process, and ammonia escape, so as to reduce system energy consumption, ensure denitrification efficiency, and avoid ammonia escape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

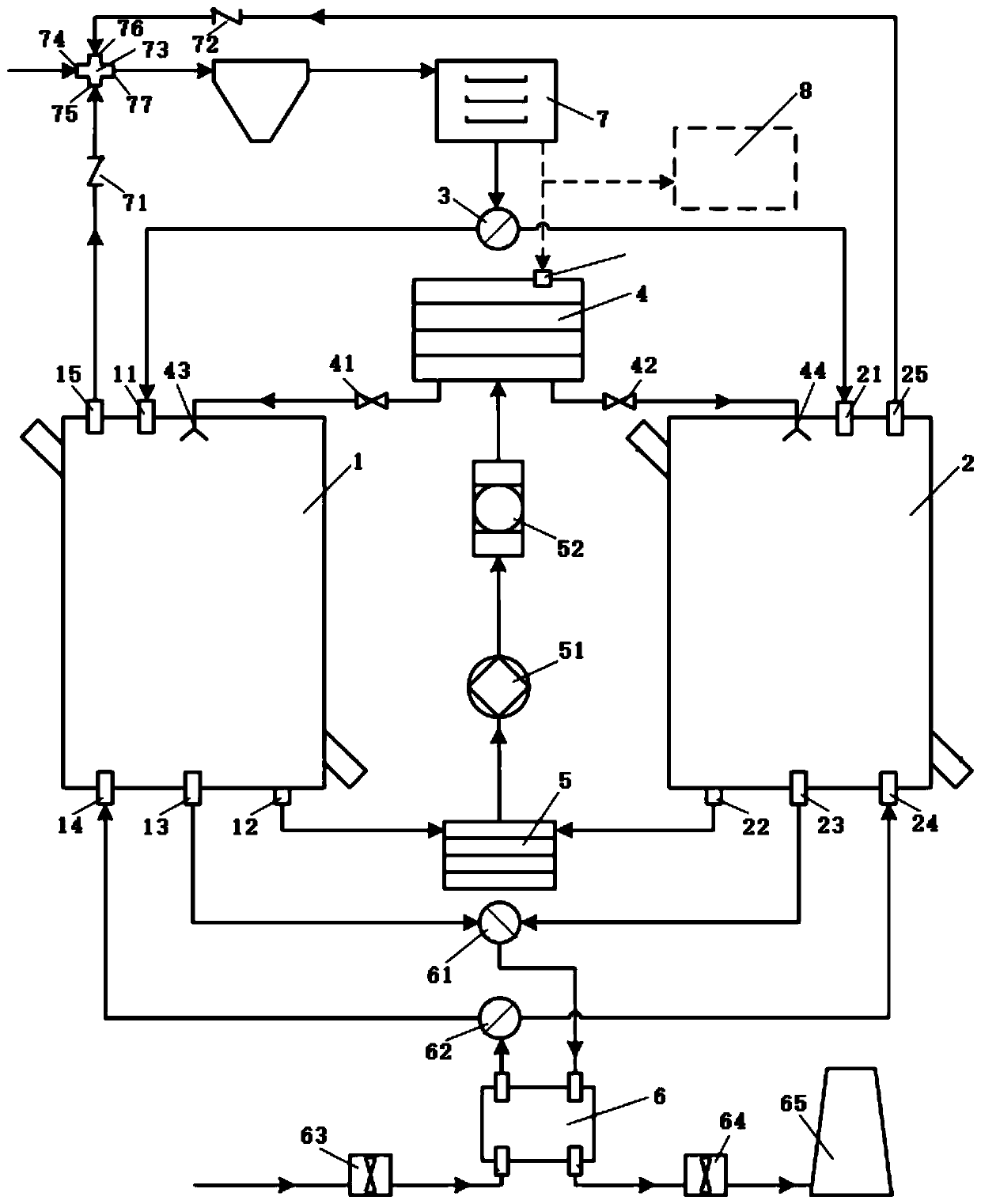

[0045] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

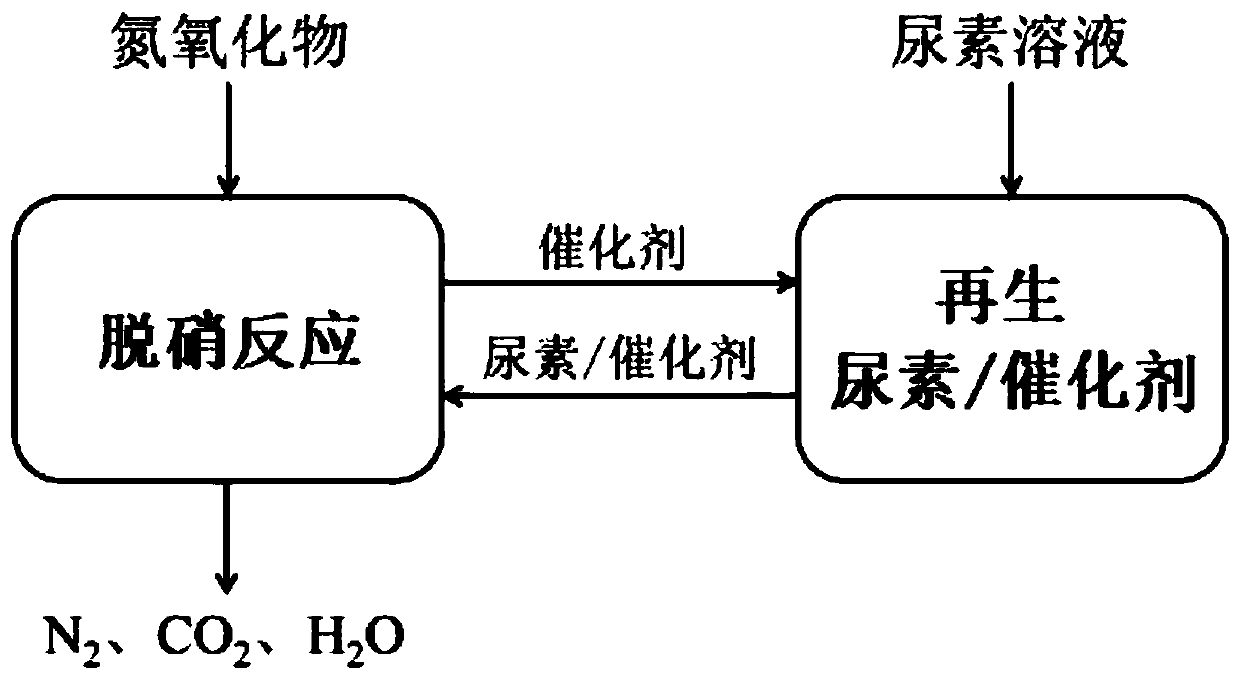

[0046] Loading urea on the surface of activated carbon or activated carbon fiber can be directly used for low-temperature flue gas denitration treatment. Among them, activated carbon or activated carbon fiber is used as a catalyst to promote the reaction of nitrogen oxides in low-temperature flue gas with urea loaded on the catalyst to generate non-toxic nitrogen, water vapor and carbon dioxide. The specific reaction is as follows:

[0047] 6NO+2CH 4 N 2 O→5N 2 +2CO 2 +4H 2 o

[0048] 2NO+O 2 →2NO 2

[0049] 6NO 2 +4CH 4 N 2 O→7N 2 +4CO 2 +8H 2 o

[0050] NO+NO 2 +CH 4 N 2 O→2N 2 +CO 2 +2H 2 o

[0051] Preferably, the catalyst is selected from activated carbon loaded with metal oxides or activated carbon fibers loaded with metal oxides, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com