Heat dissipation device

A technology for heat sinks and chambers, applied in cooling/ventilation/heating transformation, etc., can solve the problems of complicated welding and assembly process, inconvenient installation and arrangement of electronic equipment, difficult piping arrangement, etc., so as to save labor costs and piping. Ease of layout, reducing the effect of assembly and soldering processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Typical implementations embodying the features and advantages of the present application will be described in detail in the following description. It should be understood that the present application can have various changes in different embodiments without departing from the scope of the present application, and that the descriptions and illustrations therein are illustrative in nature and not limiting this application.

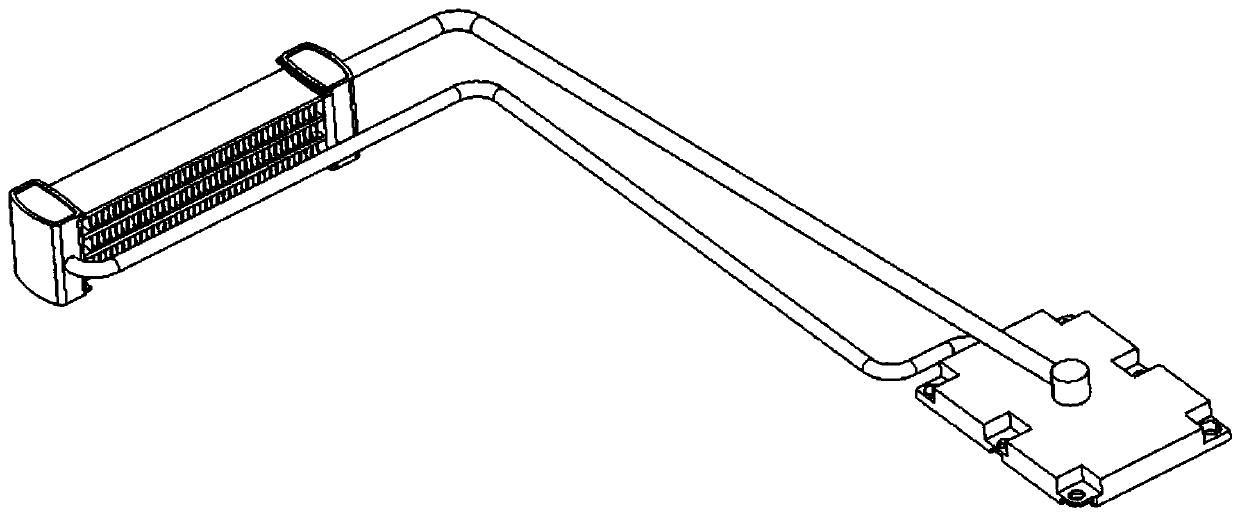

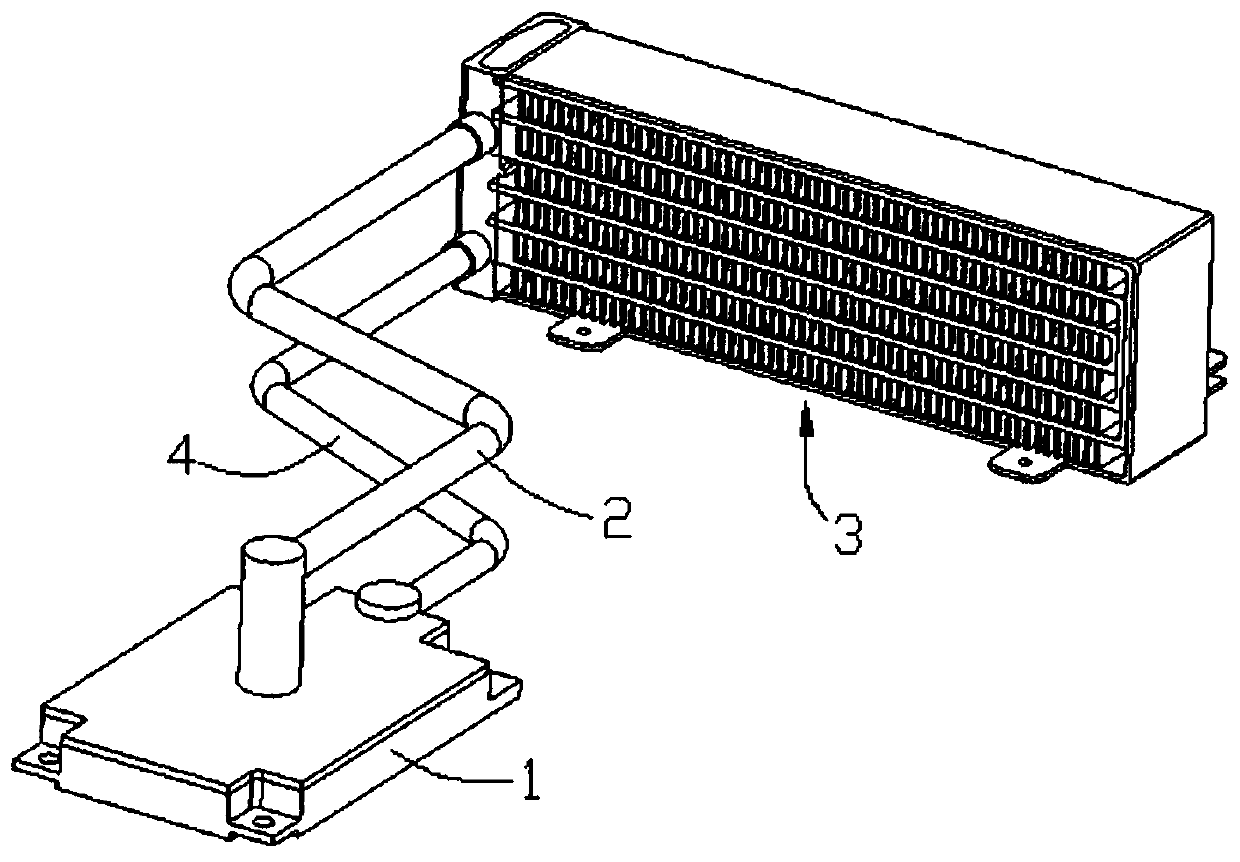

[0037] refer to Figure 2 to Figure 5 , the embodiment of the present application provides a heat dissipation device, including an evaporator 1 , a steam pipe 2 , a condenser 3 and a liquid pipe 4 .

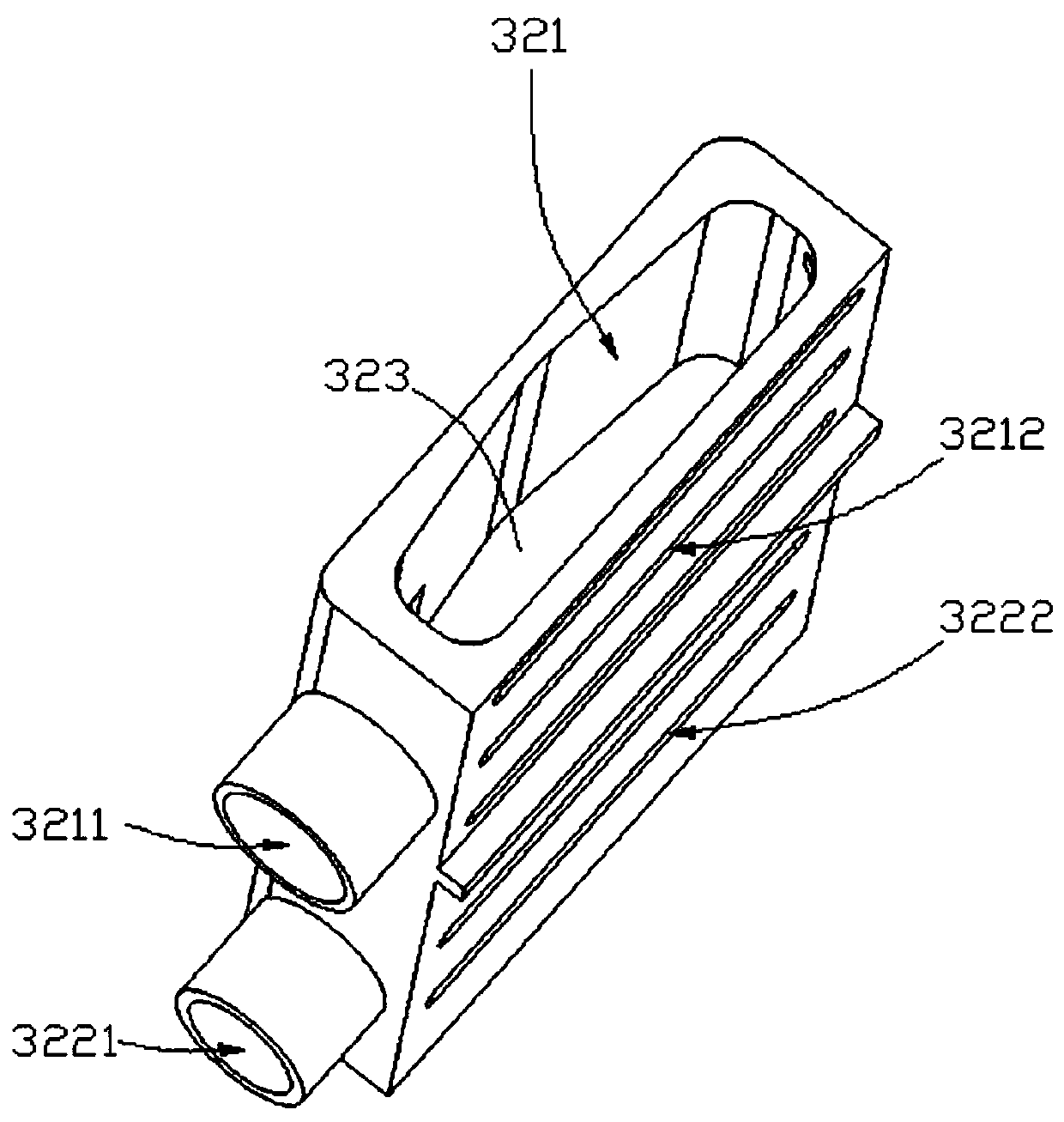

[0038] The condenser 3 is used to condense the gaseous working medium into a liquid working medium, and includes a flat tube 31 , a collector 32 , fins 33 and a protective frame 34 . Wherein, the collector body 32 is provided with an upper chamber 321 and a lower chamber (not shown in the figure), the upper chamber 321 is used to collect and accommodat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com