Drilling fluid displacement determination method meeting cleaning requirement of special-shaped borehole

A technology for determining methods and drilling fluids, applied in wellbore/well components, flushing wellbore, earthwork drilling and production, etc., to achieve the effect of safe and efficient drilling and reasonable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] (1) Obtain the basic drilling parameters as shown in Table 1:

0.216

Drill pipe outer diameter Dp,m

0.127

Drilling fluid density ρ m, ,kg / m 3

1750

cuttings density ρ d ,kg / m 3

2700

Cuttings equivalent diameter Dd,m

0.005

Well diameter enlargement rate

100%

Initial cuttings concentration at borehole enlargement

10%

[0090] Table 1

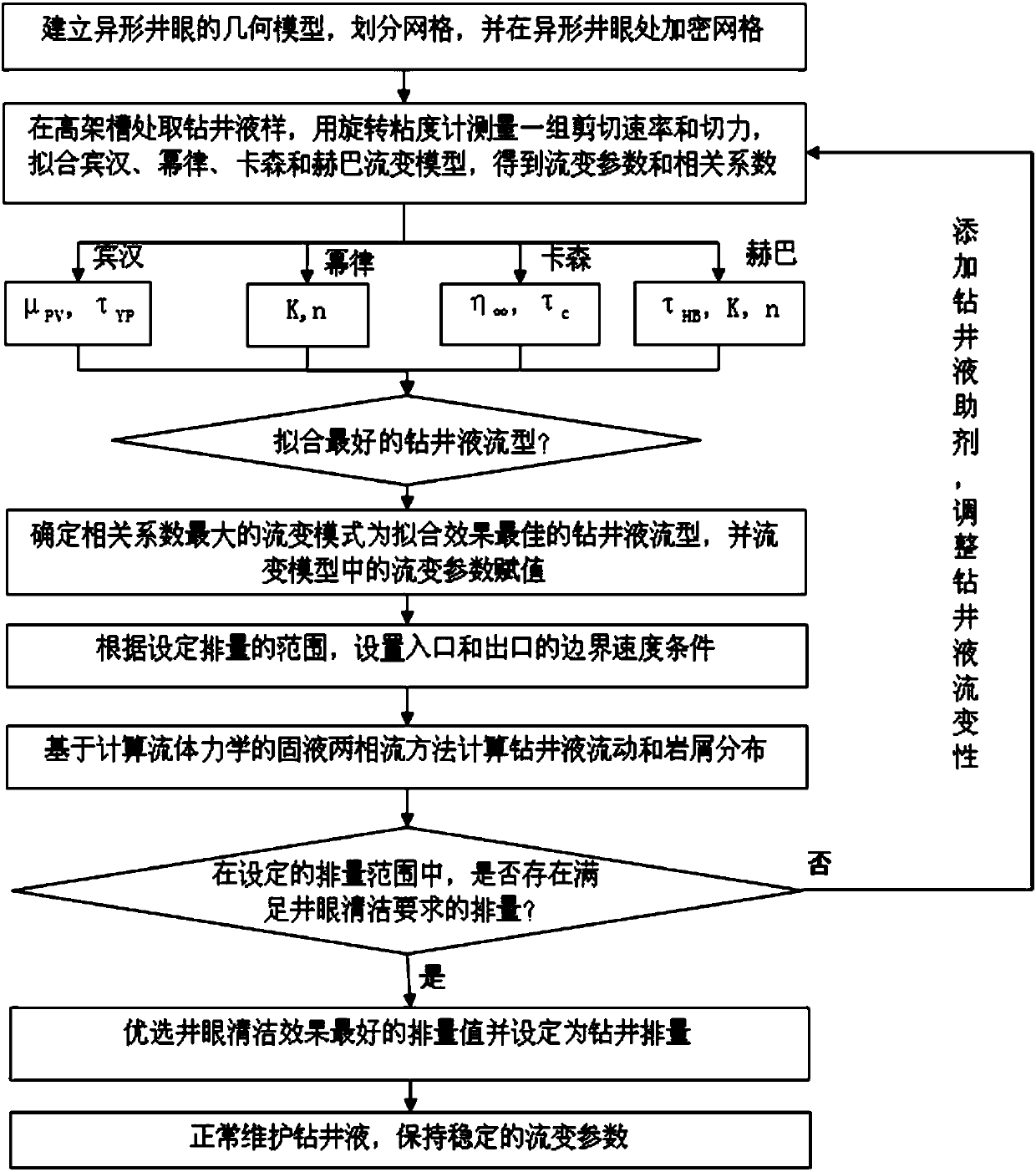

[0091] (2) Establish the geometric model of the special-shaped wellbore, divide the grid, and intensify the grid at the special-shaped wellbore, such as figure 2 shown.

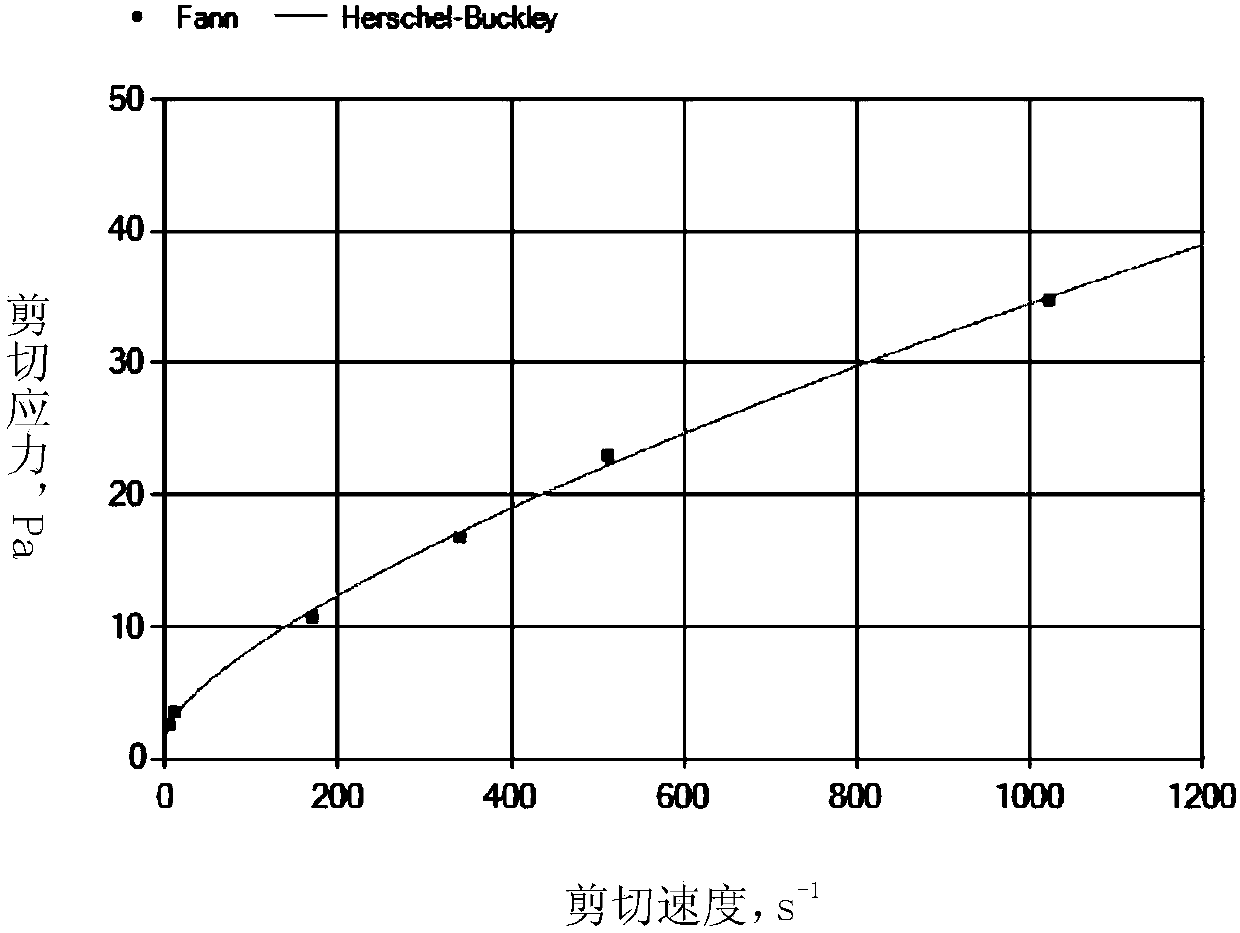

[0092] (3) Drilling fluid samples were taken at the elevated trough, and a set of shear rate and shear force was measured with a rotational viscometer, as shown in Table 2.

[0093]

[0094] Table 2

[0095] According to the shear rate and shear force, regression fit the Bingham flow rheological model, and calculate the correlation coefficient of each...

Embodiment 2

[0102] The basic parameters of drilling and the shape of the special-shaped wellbore are the same as in Example 1. Under the rheological conditions of the drilling fluid in Example 1, there is no displacement range that meets the requirements of wellbore cleaning. In Example 2, by adding drilling fluid additives , to adjust the rheology of drilling fluid. The adjusted drilling fluid rheology is shown in Table 4.

[0103] Rotational viscometer speed, r / min

600

300

200

100

6

3

Shear rate, / s

1022

511

340.7

170.3

10.2

5.11

Rotational viscometer reading θ

172

128

99

71

36

27

Shear force τ, Pa

87.9

65.4

50.6

36.3

18.4

13.8

[0104] Table 4

[0105] According to the shear rate and shear force, four rheological models were fitted by regression, and the Herba-Ba model with the largest correlation coefficient was determined as the rheological type for calculation, as shown in Tab...

Embodiment 3

[0112] (1) Obtain the basic drilling parameters as follows:

[0113] Drill diameter D b , m

0.216

Drill pipe outer diameter Dp,m

0.127

Drilling fluid density ρ m, ,kg / m 3

1800

cuttings density ρ d ,kg / m 3

2700

Cuttings equivalent diameter Dd,m

0.005

Well diameter enlargement rate

79%

Initial cuttings concentration at borehole enlargement

10%

[0114] Table 6

[0115] (2) Establish the geometric model of the special-shaped wellbore, divide the grid, and intensify the grid at the special-shaped wellbore, such as Figure 13 shown.

[0116] (3) Drilling fluid samples were taken at the elevated trough, and a set of shear rates and shear forces were measured with a rotational viscometer, as shown in Table 7.

[0117]

[0118] Table 7

[0119] According to the shear rate and shear force, four rheological models are regression fitted, and the correlation coefficients of each model are calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com