Displacement amplification type rotary friction damper

A friction damper, rotary technology, applied in building types, protective buildings/shelters, buildings, etc., can solve the problems of easy displacement of the damper, poor energy consumption, unfavorable promotion and application, etc., and achieve good quality. Amplification effect, strong energy consumption ability, avoiding the effect of excessive displacement stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0018] In order to facilitate a unified review of the various reference signs in the drawings of the specification, the unified description of the reference signs appearing in the drawings of the specification is as follows:

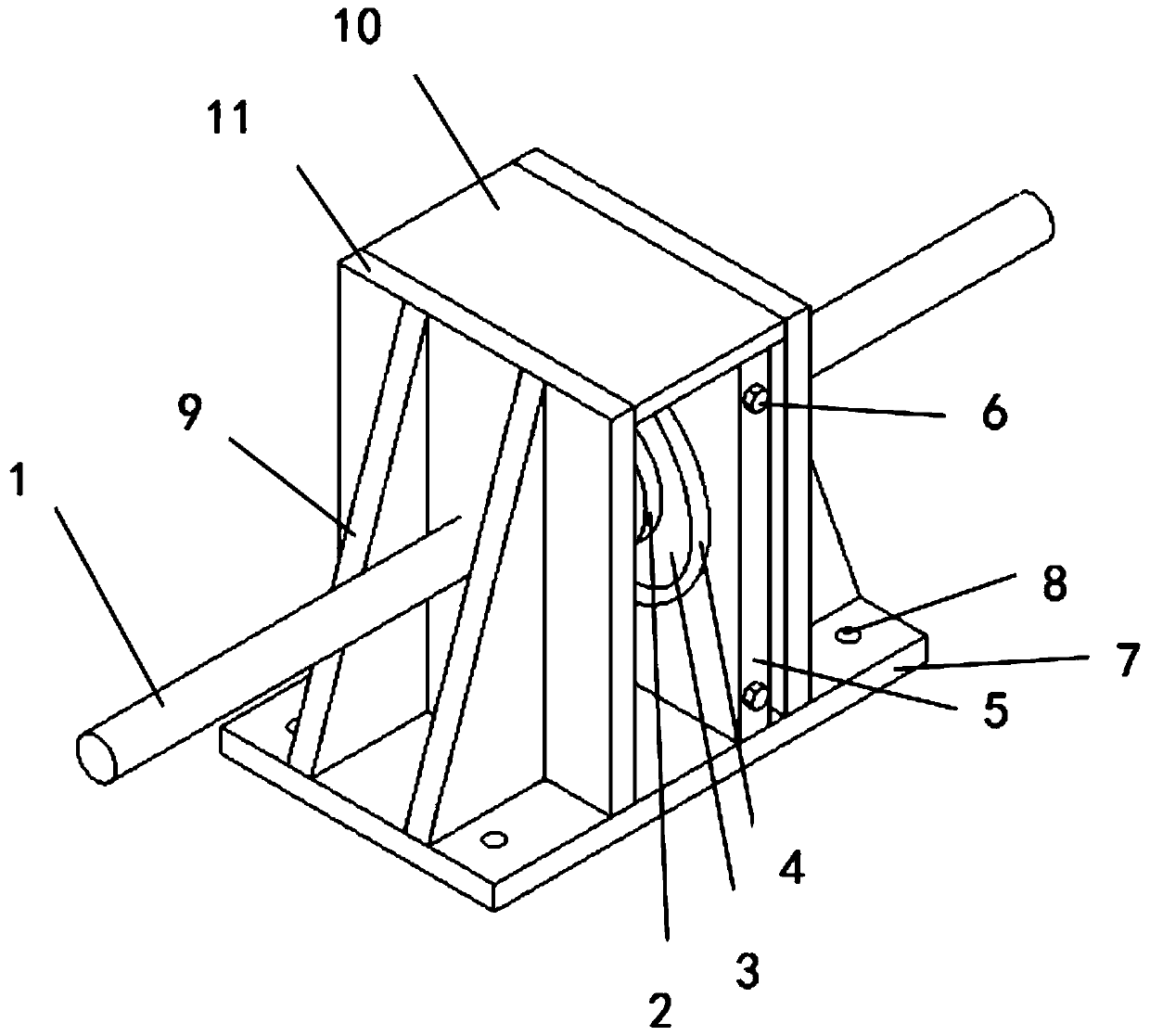

[0019] 1. Ball screw; 2. Ball nut; 3. Annular steel plate; 4. Friction plate; 5. Fixed steel plate; 6. Pre-tightening bolt; 7. Flat bottom plate; 8. Mounting hole; ; 10, top plate; 11, vertical plate; 12, thrust bearing.

[0020] combine figure 1 , figure 2 , image 3 As shown, a rotary friction damper with displacement amplification includes a base, a movable ball screw, a ball nut threaded with the ball screw, and a ring-shaped steel plate fixed on the end face of the ball nut. Fixed steel plates on the base, friction plates. The ball screw can reciprocate linearly in the horizontal direction, the ball nut is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com