Metal-rubble composite preform for island protection

A technology of composite materials and prefabricated parts, applied in building insulation materials, protective buildings/shelters, building components, etc., can solve the problems of small island area, poor feasibility, and high transportation costs, and achieve low overall cost and on-site construction The effect of simplicity, high strength and impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings.

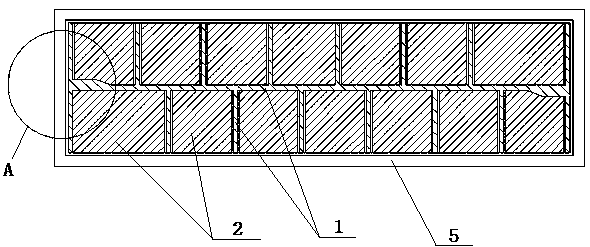

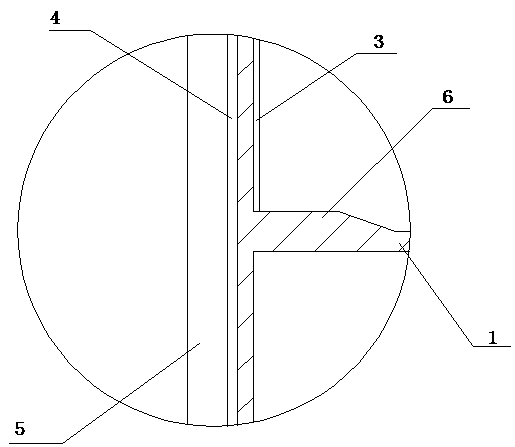

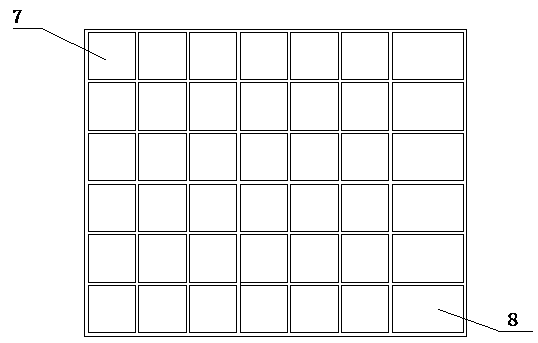

[0019] Such as figure 1 , figure 2 , image 3 As shown, a metal / block stone composite material prefabricated part for island protection includes: a cuboid body, the outside of which is covered with a fluorocarbon paint protective layer 4, and the outer wrapping of the fluorocarbon paint protective layer 4 Covered with a mortar protection layer 5, the body is composed of a metal-based box 1 and a block stone 2, and the block stone 2 is fixedly installed in the metal-based box 1 through an adhesive material layer 3, and the metal-based box 1 The whole is a two-layer cuboid box structure composed of several cells. The cells as a whole are a box structure with one end open. Downward, each cell is provided with a block stone 2, and the size of the block stone 2 matches the inner cavity of the cell, and the block stone 2 and each side wall of the cell pass thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com