Biological activity ceramic bracket with heterogeneous porous bionic natural bone structure and preparation method of biological activity ceramic bracket

A technology of bioactive ceramics and bioceramics, which is applied in the field of 3D printing, can solve the problems of reducing the yield of fired products, the inability to accurately control the pore size of heterogeneous porous structures, and fractures, and achieve the effect of continuous change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

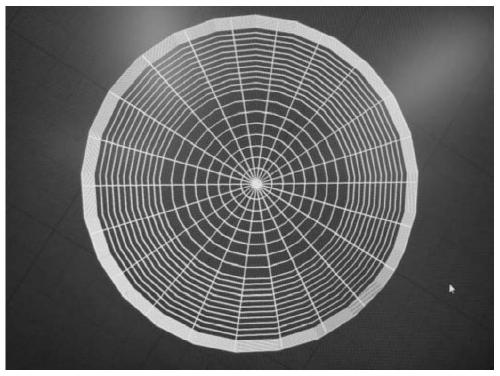

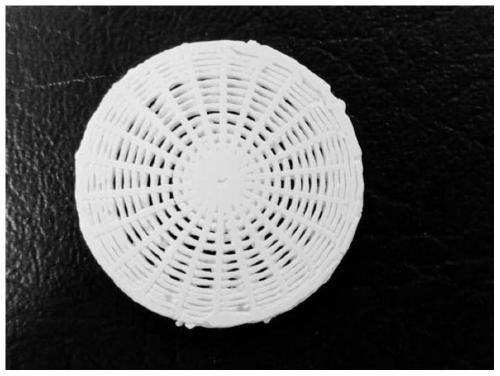

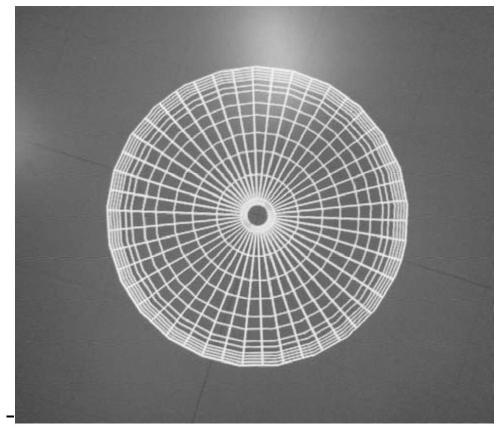

Image

Examples

Embodiment 1

[0033] The preparation of a kind of heterogeneous porous (pore diameter is 50-1200 μm from outside to inside) biomimetic natural bone structure bioactive ceramic support is as follows:

[0034] Step 1: Synthesis of β-tricalcium phosphate powder for 3D printing

[0035] (1) 850.14g Ca(NO 3 ) 2 4H 2 O and 180g PEG (6000) were dissolved in deionized water, stirred at room temperature to obtain a 0.3M calcium source solution;

[0036] (2) 316.944g, 0.2M (NH 4 ) 2HPO 4 The solution is added dropwise to (1) the calcium source solution, and the pH value of the solution is adjusted to 6.5 with ammonia water to form a precipitate;

[0037] (3) stirring for 8 hours, aging for 1 day, washing with deionized water until neutral;

[0038] (4) Freeze-drying for 2 days and incubating at 700°C for 2 hours to obtain spherical β-tricalcium phosphate powder;

[0039] Step 2: Preparation of high solid content slurry (solid content is 45vt%)

[0040] (1) 7ml deionized water is added in the...

Embodiment 2

[0051] The preparation of a kind of heterogeneous porous (pore diameter is 250-2000 μm from outside to inside) bionic natural bone structure bioactive ceramic scaffold is as follows:

[0052] Step 1: Synthesis of β-tricalcium phosphate powder for 3D printing

[0053] (1) 1700.28g Ca(NO 3 ) 2 4H 2 O and 360g PEG (6000) were dissolved in deionized water, stirred at normal temperature to obtain a 0.6M calcium source solution;

[0054] (2) 633.888g, 0.4M (NH 4 ) 2 HPO 4 The solution is added dropwise to (1) the calcium source solution, and the pH value of the solution is adjusted to 7 with ammonia water to form a precipitate;

[0055] (3) stirring for 10 hours, aging for 2 days, washing with deionized water until neutral;

[0056] (4) Freeze-drying for 3 days and incubating at 800° C. for 3 hours to obtain spherical β-tricalcium phosphate powder;

[0057] Step 2: Preparation of high solid content slurry (solid content is 48vt%)

[0058] (1) 9ml deionized water is added in...

Embodiment 3

[0069] The preparation of a kind of heterogeneous porous (pore diameter is 400-3000 μm from outside to inside) bionic natural bone structure bioactive ceramic support is as follows:

[0070] Step 1: Synthesis of β-tricalcium phosphate powder for 3D printing

[0071] (1) 8500.14g Ca(NO 3 ) 2 4H 2 0 and 1800g PEG (6000) were dissolved in deionized water, stirred at normal temperature to obtain a 3M calcium source solution;

[0072] (2) 3169.44g, 2M (NH 4 ) 2 HPO 4 The solution is added dropwise to (1) the calcium source solution, and the pH value of the solution is adjusted to 6.8 with ammonia water to form a precipitate;

[0073] (3) stirring for 12 hours, aging for 3 days, washing with deionized water until neutral;

[0074] (4) Freeze-drying for 4 days and incubating at 800° C. for 3 hours to obtain spherical β-tricalcium phosphate powder;

[0075] Step 2: Preparation of high solid content slurry (solid content is 55vt%)

[0076] (1) 9ml deionized water is added in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com