Carbide-free bainite self-reinforced gear steel and preparation method

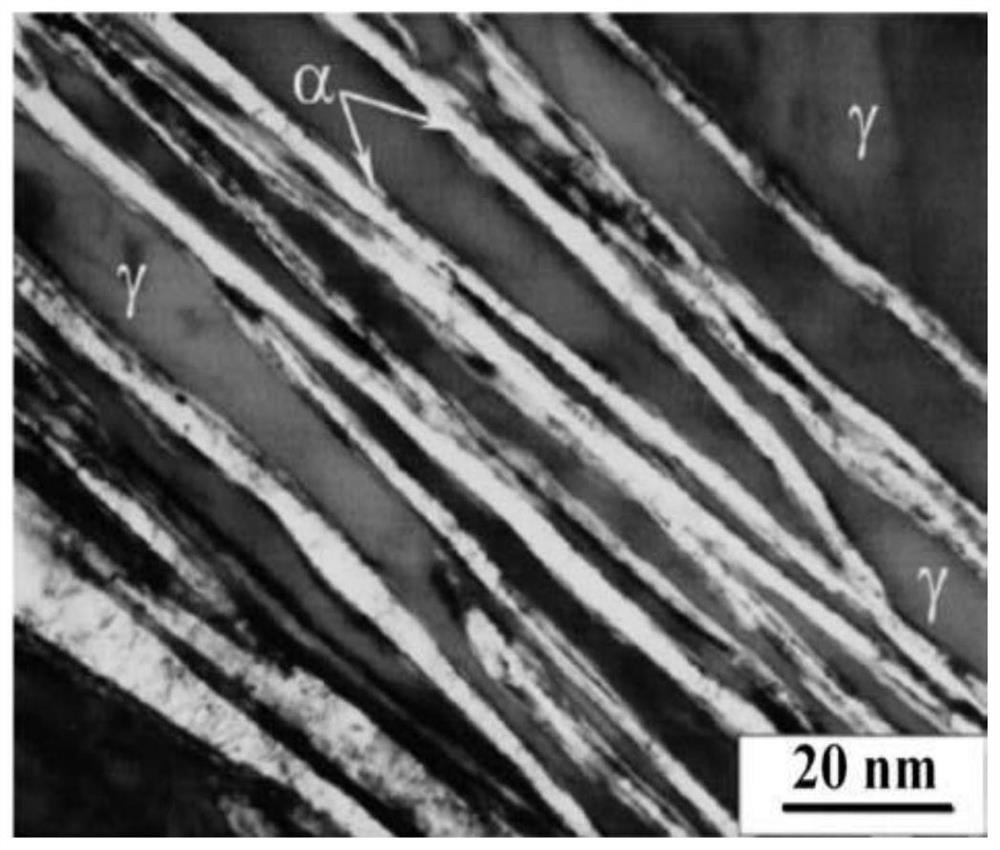

A technology of bainite and carbide, which is applied in the field of carbide-free bainite self-strengthening gear steel and its preparation, to achieve the effects of crack propagation self-strengthening, higher strength and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Self-strengthening gear steel 1 without carbide bainite, its chemical composition is calculated by weight percentage: C: 0.13wt%, Si: 0.93wt%, Mn: 1.50wt%, Al: 3.7wt%, P: 0.005 wt%, S: 0.005wt%, W: 0.25wt%, V: 0.065wt%, the rest is Fe and unavoidable impurities.

[0030] The preparation method of the above-mentioned carbide-free bainite self-reinforced gear steel 1, the method is smelted according to the above-mentioned chemical composition according to traditional smelting to obtain a self-reinforced gear steel whose microstructure is carbide-free bainite, wherein,

[0031] 1) During the billet casting process, controlled rolling and controlled cooling are carried out after being heated by the heating furnace: the temperature in the finishing rolling stage is controlled at 890°C, and the temperature is controlled at 3S -1 The deformation rate is the last 10% deformation rolling, and the final rolling temperature is 850°C;

[0032] 2) After rolling, the finished produc...

Embodiment 2

[0035] Carbide-free bainite self-strengthening gear steel 2, its chemical composition is calculated by weight percentage: C: 0.12wt%, Si: 0.85wt%, Mn: 1.43wt%, Al: 3.5wt%, P: 0.005 wt%, S: 0.005wt%, W: 0.25wt%, V: 0.068wt%, the rest is Fe and unavoidable impurities.

[0036] The preparation method of the above-mentioned carbide-free bainite self-strengthening gear steel 2, the method is smelted according to the above-mentioned chemical composition according to the traditional smelting to obtain the self-strengthening gear steel whose microstructure is carbide-free bainite, wherein,

[0037] 1) During the billet casting process, controlled rolling and controlled cooling are carried out after being heated by the heating furnace: the temperature in the finishing rolling stage is controlled at 930°C, and the temperature is controlled at 3S -1 The deformation rate is the last 10% deformation rolling, and the final rolling temperature is 830°C;

[0038] 2) After rolling, the finish...

Embodiment 3

[0041] Carbide-free bainite self-strengthening gear steel 3, its chemical composition is calculated by weight percentage: C: 0.13wt%, Si: 0.88wt%, Mn: 1.42wt%, Al: 3.3wt%, P: 0.005 wt%, S: 0.006wt%, W: 0.26wt%, V: 0.058wt%, the rest is Fe and unavoidable impurities.

[0042] The preparation method of the above-mentioned carbide-free bainite self-reinforced gear steel 3, the method is smelted according to the above-mentioned chemical composition according to traditional smelting to obtain a self-reinforced gear steel with a carbide-free bainite microstructure, wherein,

[0043] 1) During the billet casting process, controlled rolling and controlled cooling are carried out after being heated by the heating furnace: the temperature in the finishing rolling stage is controlled at 920°C, and the temperature is controlled at 5S -1 The deformation rate is the last 10% deformation rolling, and the final rolling temperature is 820°C;

[0044] 2) After rolling, the finished product is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com