3D continuous route generation method for fused deposition manufacturing

A fused deposition manufacturing and path generation technology, applied in the field of additive manufacturing, can solve problems such as difficulty, increase maintenance costs, and unstable operation, and achieve the effect of reducing difficulty, saving printing time, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Preferred implementation example of the present invention, in conjunction with accompanying drawing, describe in detail as follows:

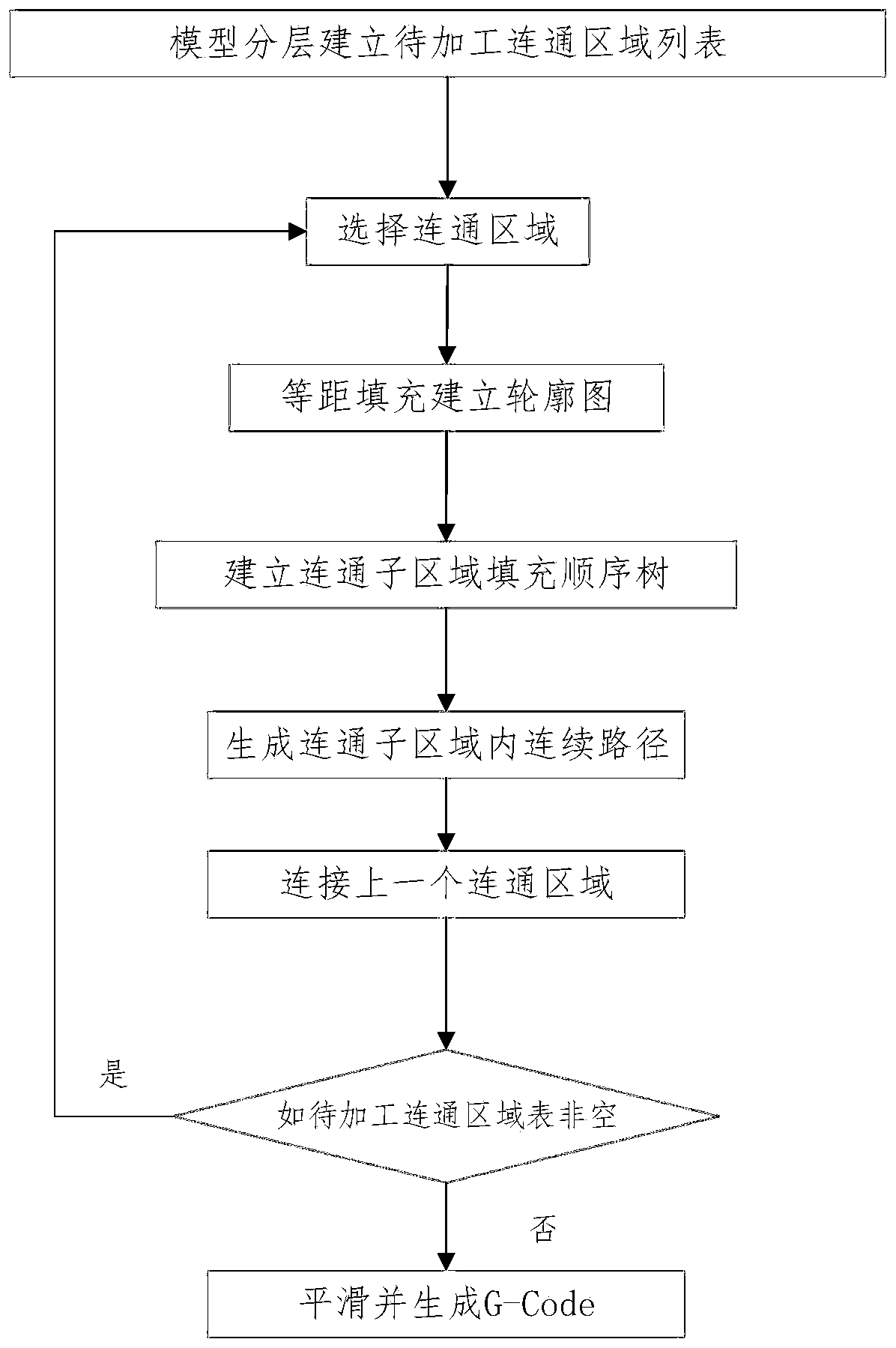

[0043] figure 1 It is a flowchart of a rule-based body structure evolution design method of the present invention, and the steps are as follows:

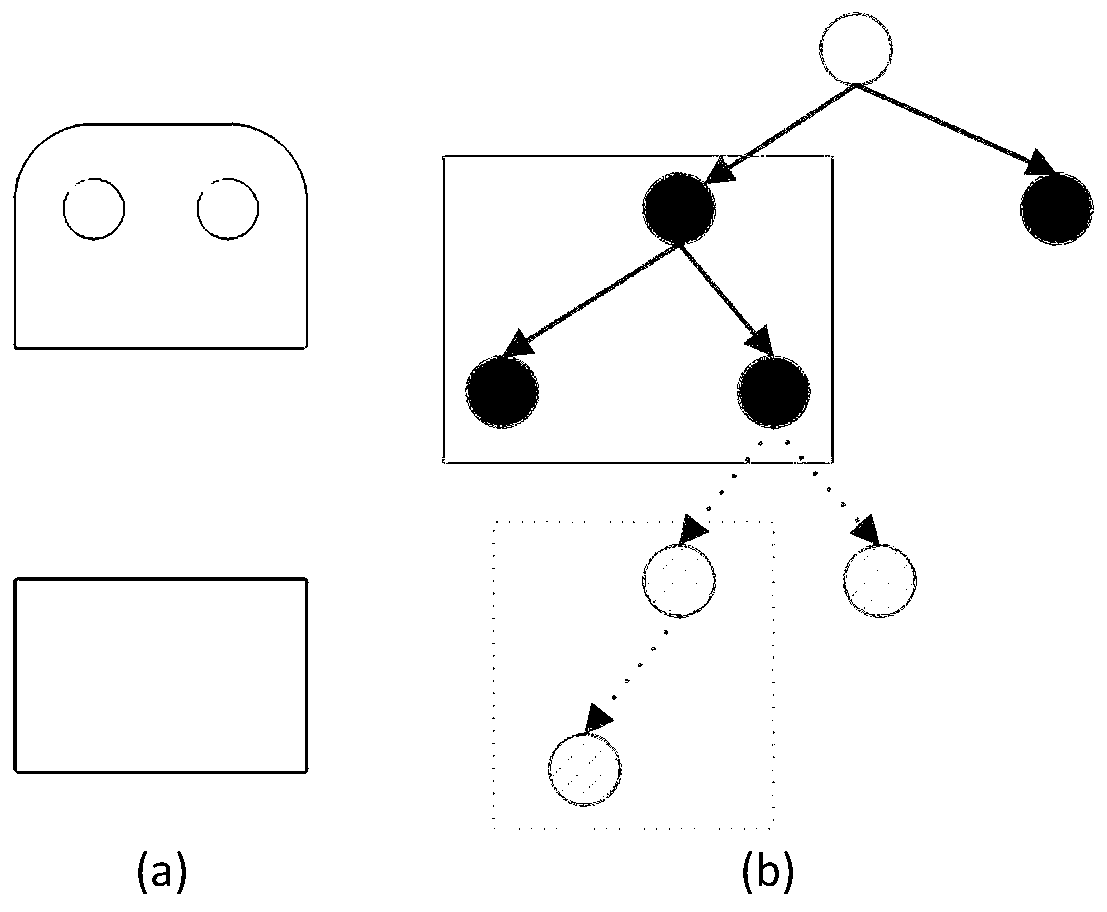

[0044] (1) Obtain a set of slices of the processed triangular patch model according to the printing direction and layer thickness, and a set of two-dimensional cross-sectional contours on each slice, such as figure 2 (a). Generate a connected region tree according to the two-dimensional contour set, traverse the connected region tree, and obtain the closed boundary of each given connected region;

[0045](2) Starting from the connected region with the largest area in the first layer slice, visit each layer in turn, select the next connected region in turn through the region area, distance and collision detection relationship, and construct the pending connected sub-region including all conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com