Board jointing machine convenient to load materials

A jigsaw machine and convenient technology, which are applied in the joining of wooden veneers, wood processing appliances, adhesive application devices, etc., can solve the problems of low efficiency of wood splicing, increase labor consumption, etc., so as to reduce labor consumption and improve sliding Stability, the effect of reducing labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

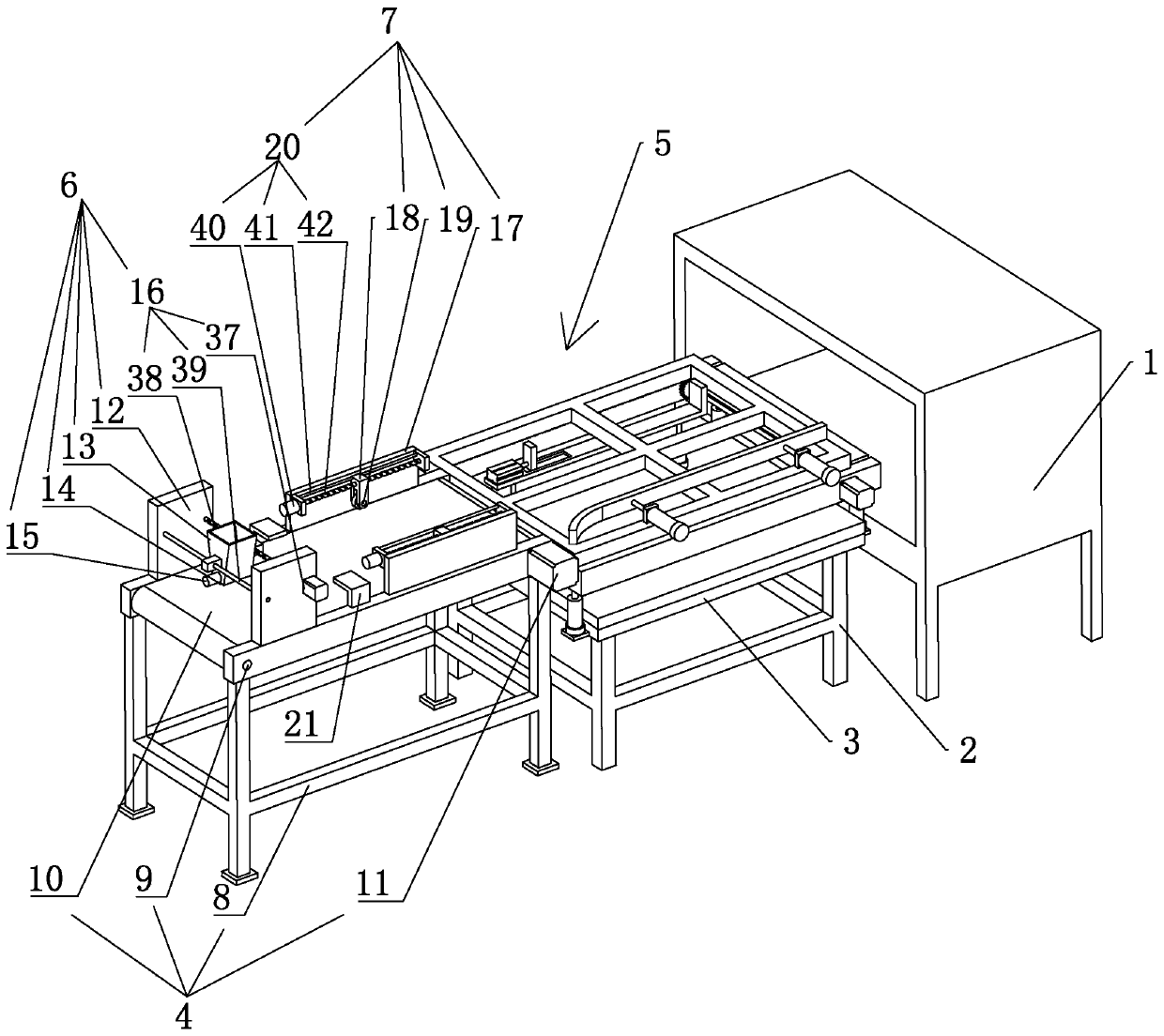

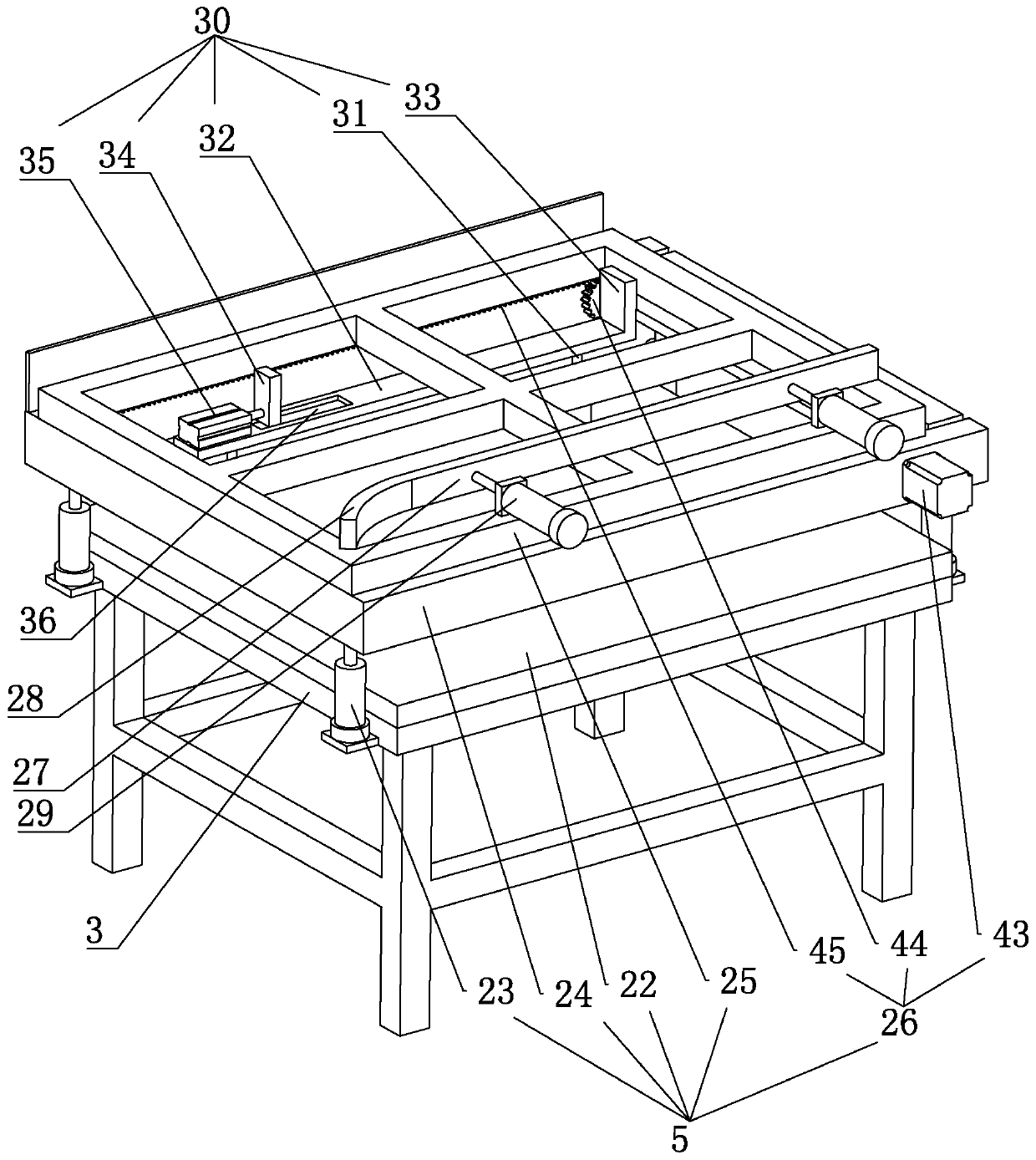

[0032] Embodiment one: if figure 1 As shown, it is a convenient loading jigsaw disclosed by the present invention, which includes a jigsaw body 1, a bracket 2 is fixedly connected to one side of the jigsaw body 1, and a workbench 3 is fixedly connected to the bracket 2 , on the support 2 is provided with a pull mechanism 4, on the workbench 3 is provided with a conveying mechanism 5 for conveying the wooden strips to the main body 1 of the jigsaw puzzle.

[0033] Such as figure 1 , figure 2 As shown, the plate-feeding mechanism 4 includes a frame 8, a rotating rod 9, a transmission belt 10 and a drive motor 11, the frame 8 is fixedly connected to one end of the support 2, and the rotating rod 9 is rotatably connected between the two ends of the frame 8. 8 Rotating rods 9 are connected to the inner walls at both ends, the transmission belt 10 is wound between two groups of rotating rods 9, the driving motor 11 is fixedly connected to the frame 8, and the output shaft of the ...

Embodiment 2

[0043] Embodiment two: the concrete steps of a kind of sofa production technology comprise:

[0044] Step 1. Select the wood, and select the wooden strips with the same length;

[0045] Step 2. Use the jigsaw machine to splice the selected wood into planks and wait for cutting;

[0046] Step 3: Cut the wooden boards to the required size with the cutting machine, and splice the cut wooden boards into the sofa skeleton with nails;

[0047] Step 4: A sponge layer is fixedly connected to the sofa frame, and the outside of the sponge layer is covered by a coating layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com