Book printing production technology and book printing production line

A production process and production line technology, used in printing, printing presses, rotary printing presses, etc., can solve the problems of difficulty in determining the position of the middle seam of the cover, increased defective book production rate, and waste of cover materials and paper. Book block bonding, saving production input costs and reducing the effect of cover sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

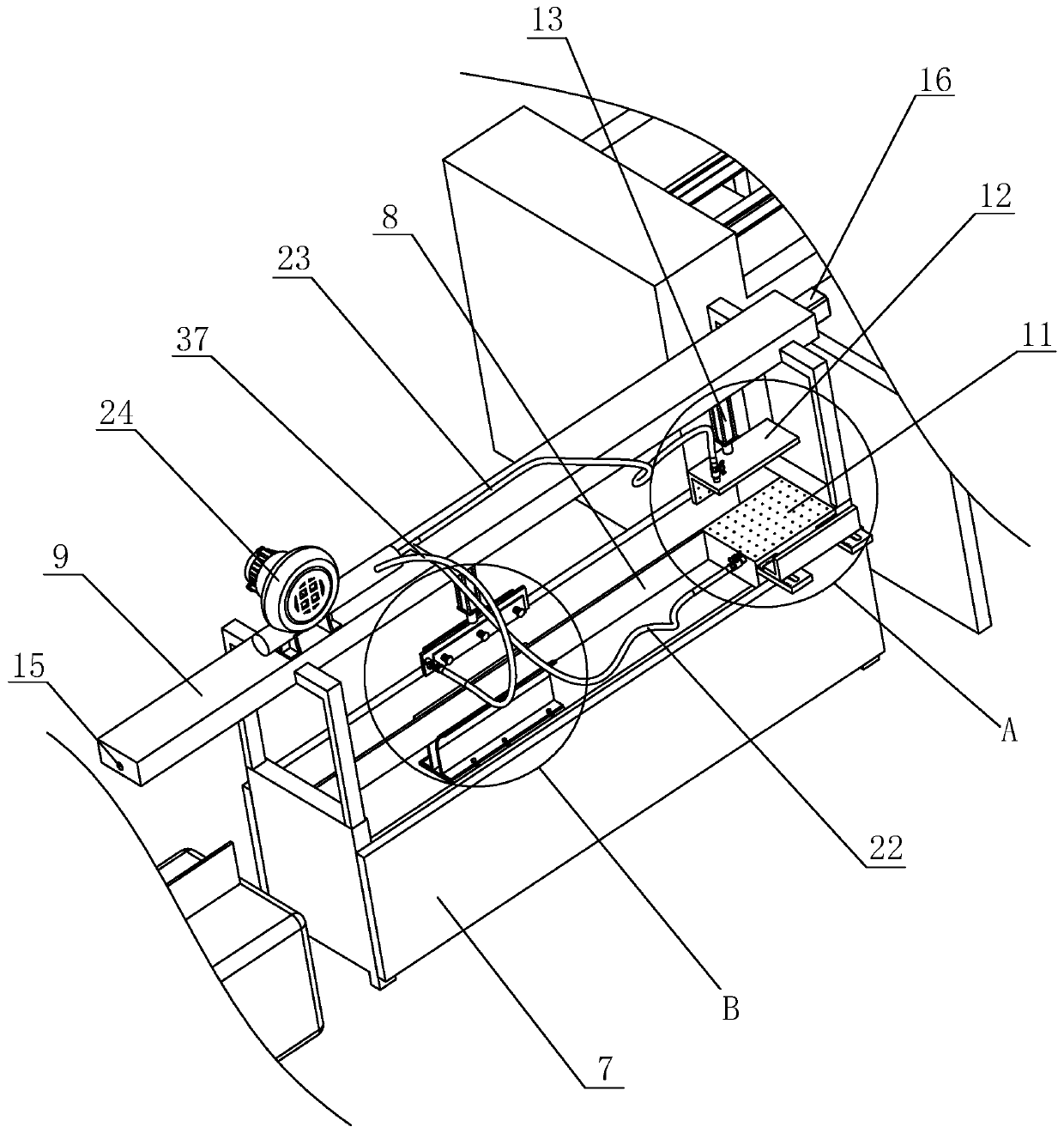

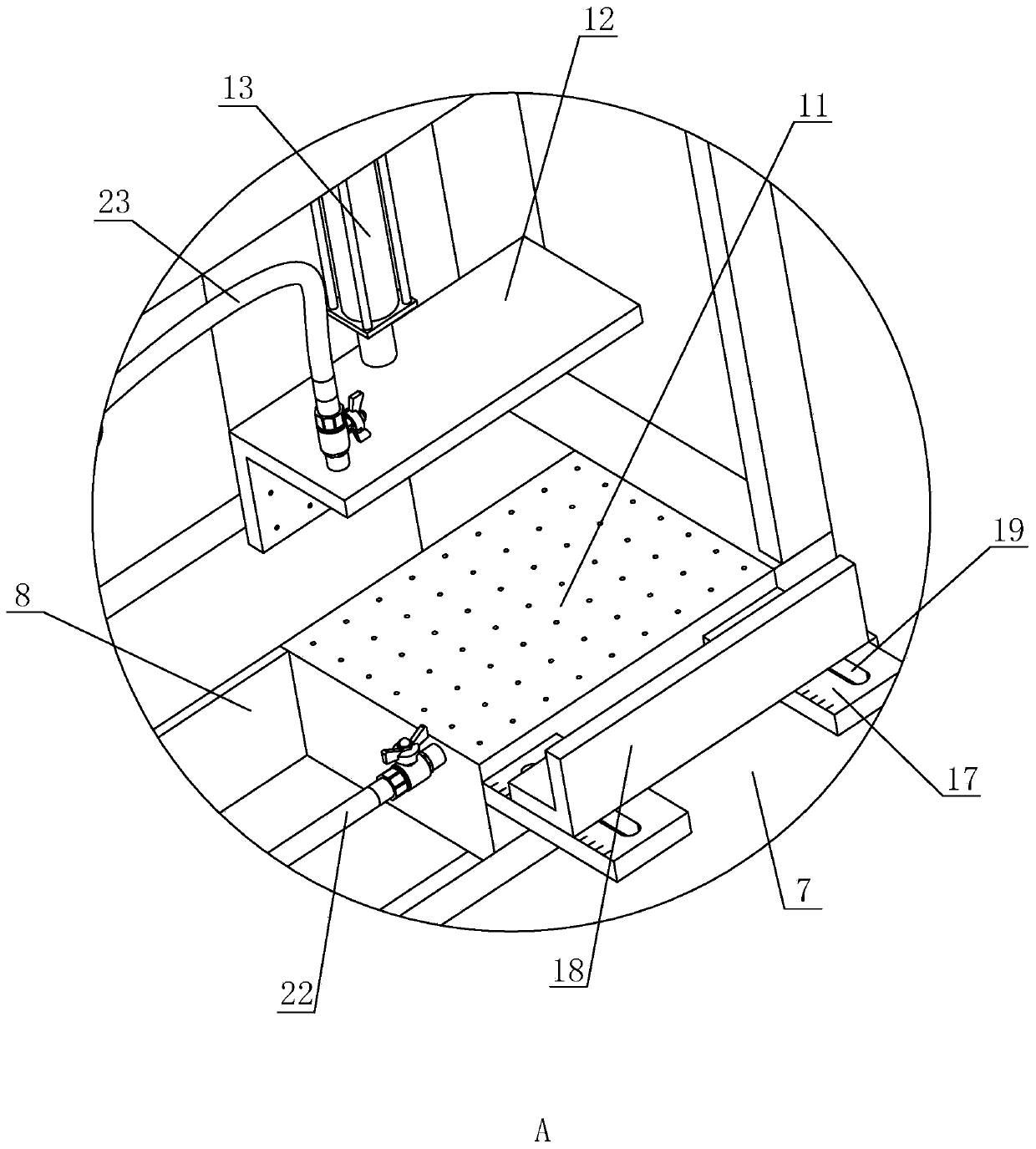

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings.

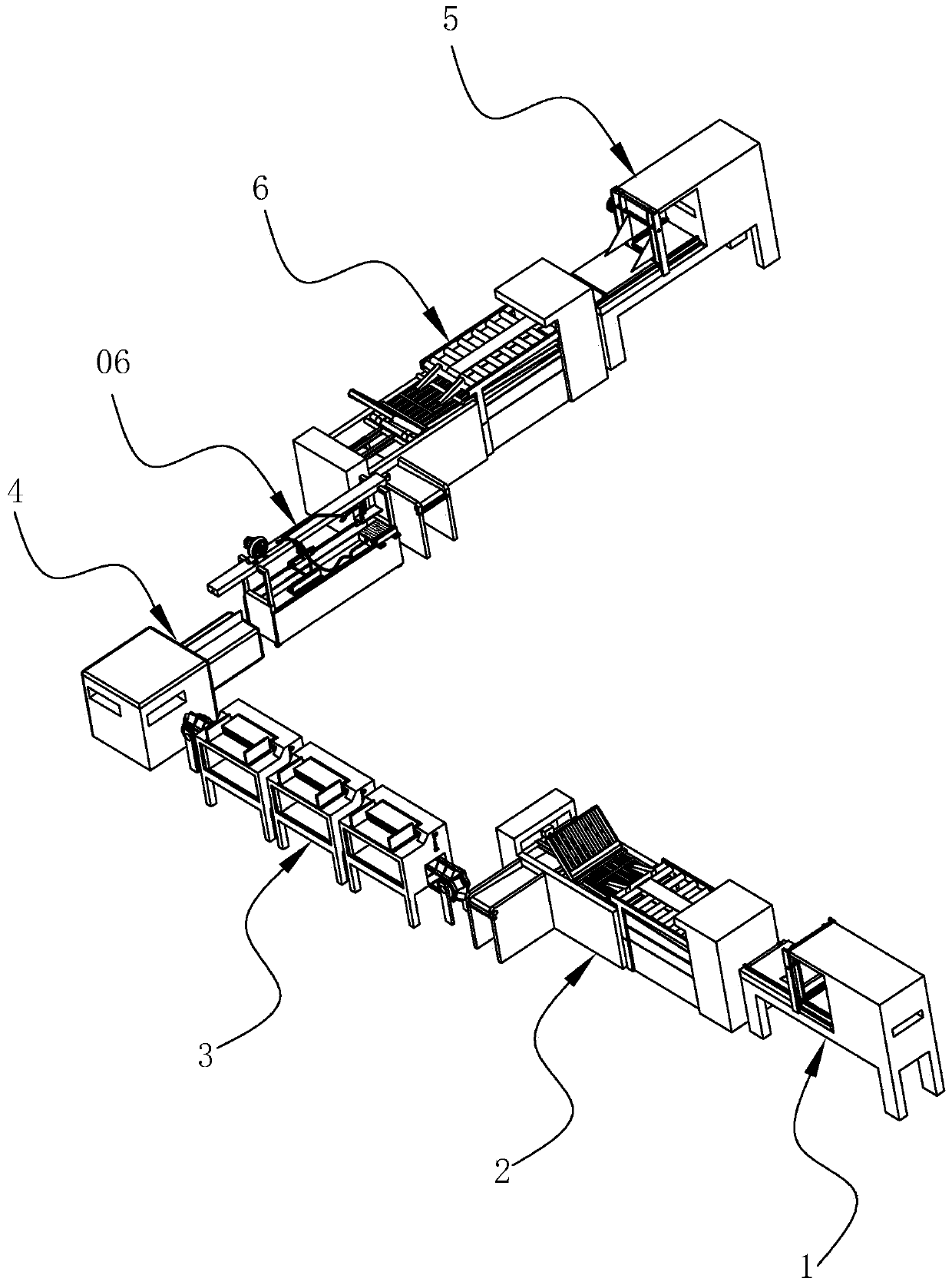

[0053] refer to figure 1 , is a book printing production line disclosed in the present invention, comprising a book block making assembly and a book cover making assembly, and the book block making assembly and the book cover making assembly are jointly connected with a glue binding machine 4 . The book block making assembly includes a book block printing machine 1 , a folding machine 2 and a collating machine 3 , the collating machine 3 is connected to a glue binding machine 4 , and the book cover making assembly includes a book cover printing machine 5 and a paper cutter 6 .

[0054] refer to figure 1 , the content of the book and the content of the book cover are plate-made, and then the printed book and the content of the book cover are printed by the printing machine, and the printed pages of the book are folded by the folding machine 2, and then the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com