Cyclone-water bath combined type dust removal simulating device

A simulation device and cyclone dust removal technology, which is applied in combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low efficiency and low cost, and achieve the effect of low production cost and increased water bath contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

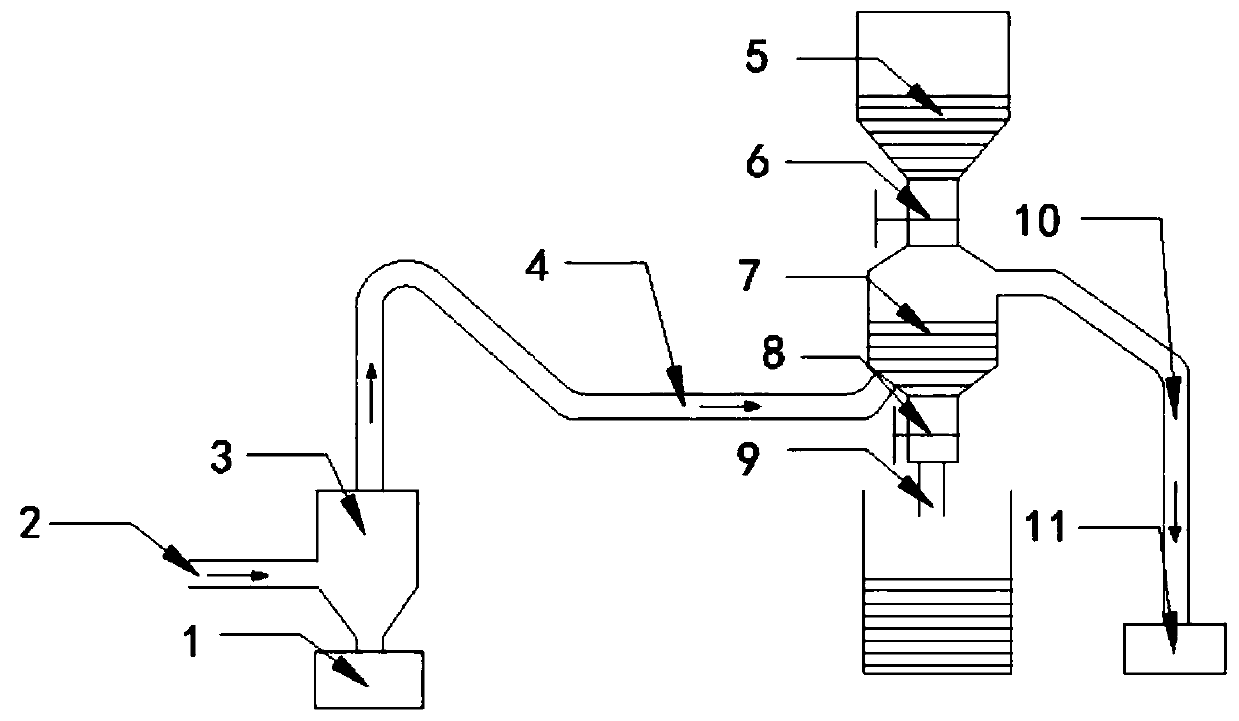

[0023] The cyclone dust collector is suitable for the removal of non-viscous and non-fibrous dust, mostly used to remove particles above 5 μm. The water bath dust collector can effectively remove liquid or solid particles with a diameter of 0.1-20 μm from the air flow, and at the same time, it can also remove some gaseous pollutants. The cyclone-water bath combined dust collector model organically combines the cyclone dust collector and the water bath dust collector to make up for their respective deficiencies, so as to achieve better dust removal effect.

[0024] see figure 1 , a cyclone-water bath combined dust removal simulation device, comprising a cyclone dust removal area and a water bath dust removal area; The ash hopper 1 is connected, the air inlet pipe 2 is connected with the bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com