Method for manufacturing crystals of aluminate of at least one metal and/or one metalloid and/or one lanthanide, and applications of same

An aluminate, element technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, alkaline earth metal aluminate/alumina/aluminum hydroxide preparation, chemical instruments and methods, etc., can solve low productivity, Difficult to industrial scale and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0051] According to a first embodiment, the method according to the invention makes it possible to produce aluminate crystals of element A. According to this embodiment, the crystals thus obtained (after calcination) may conform to the general formula: Al x A y OHZ, where 02 o 4 、CaAl 4 o 7 、LiAl 2 o 5 Wait.

[0052] Typically, z=0 (non-hydrated crystals).

[0053] According to a second embodiment, the method according to the invention makes it possible to manufacture aluminate crystals of various elements A, denoted “A1”, “A2”, “An”, etc. According to this variant, the crystals thus obtained (after calcination) may correspond, for example, to the following general formula: A1 v (Al x A2 w )O 3 , where 01 / 2 Nb 1 / 2 )O 3 , Ca(Al 1 / 2 Nb 1 / 2 )O 3 orSr(Al 1 / 2 Ta 1 / 2 )O 3 .

[0054] In general, the method according to the invention makes it possible to produce aluminate crystals of element A.

[0055] To this end, the method for producing aluminate crystals of s...

Embodiment

[0221] The description of the following tests is given by way of illustration and non-limiting example only. Results are expressed in mass unless otherwise stated.

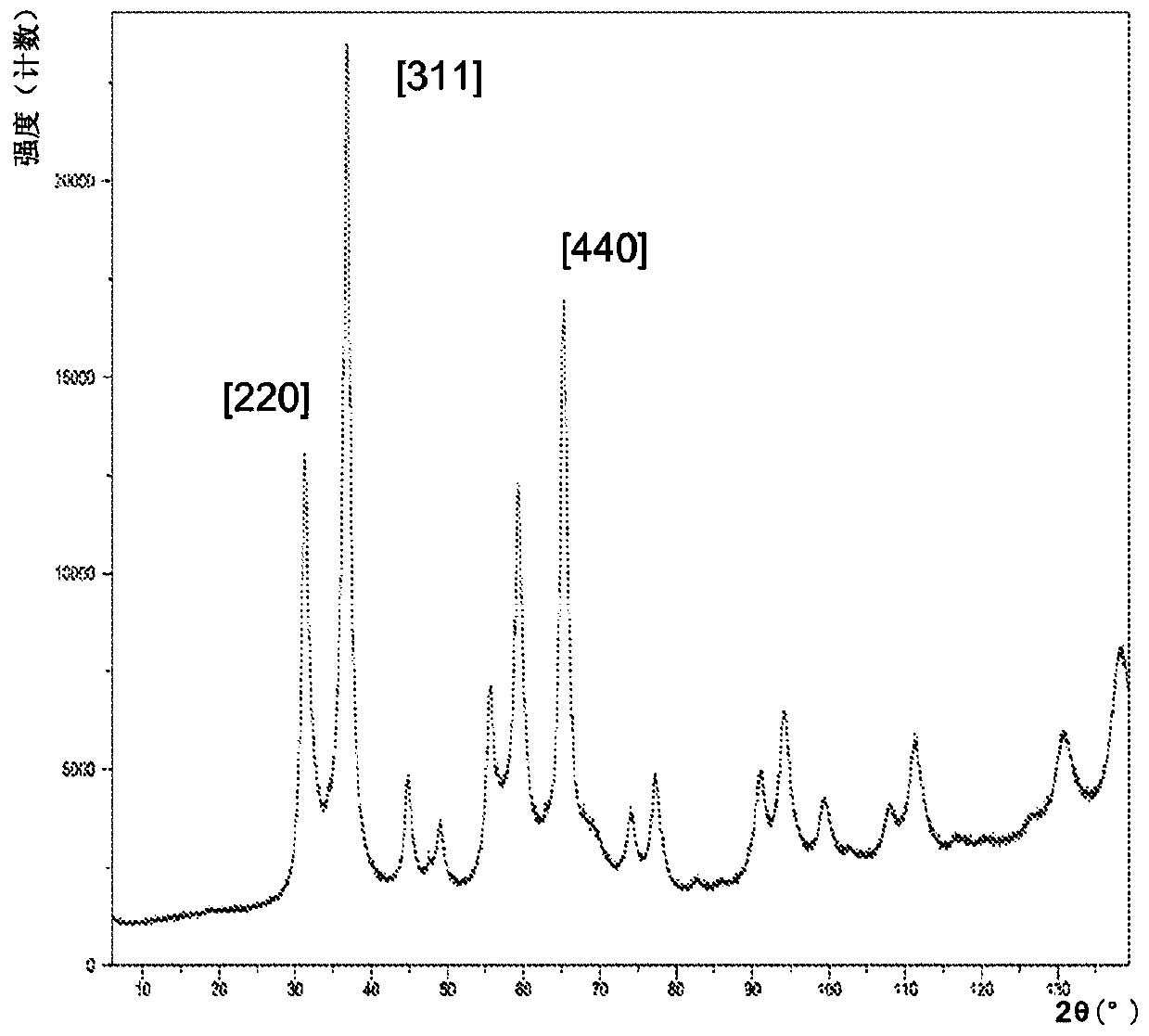

[0222] A Characterized by XRD

[0223] X-ray diffraction (XRD) spectra were collected using a D8ADVANCE Series II diffractometer sold by Bruker using CuKα1 radiation (0.15406 nm) according to a Bragg-Brentano configuration.

[0224] The detector used was a LynxEye 1D detector from Bruker. The aperture angle of the detector is 3° (150 bands).

[0225] XRD measurements were performed from 10° to 140° (2Θ scale) using a step size of 0.008° (1 sec / step).

[0226] B° Procedures for preparing test samples

[0227] equipment

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com