A method for preparing an electronic circuit on a substrate

A technology of electronic circuits and substrates, applied in the field of electrochemical processing, can solve problems such as circuit short circuit and abnormal production, and achieve the effect of improving the overflow plating situation and avoiding the overflow plating phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

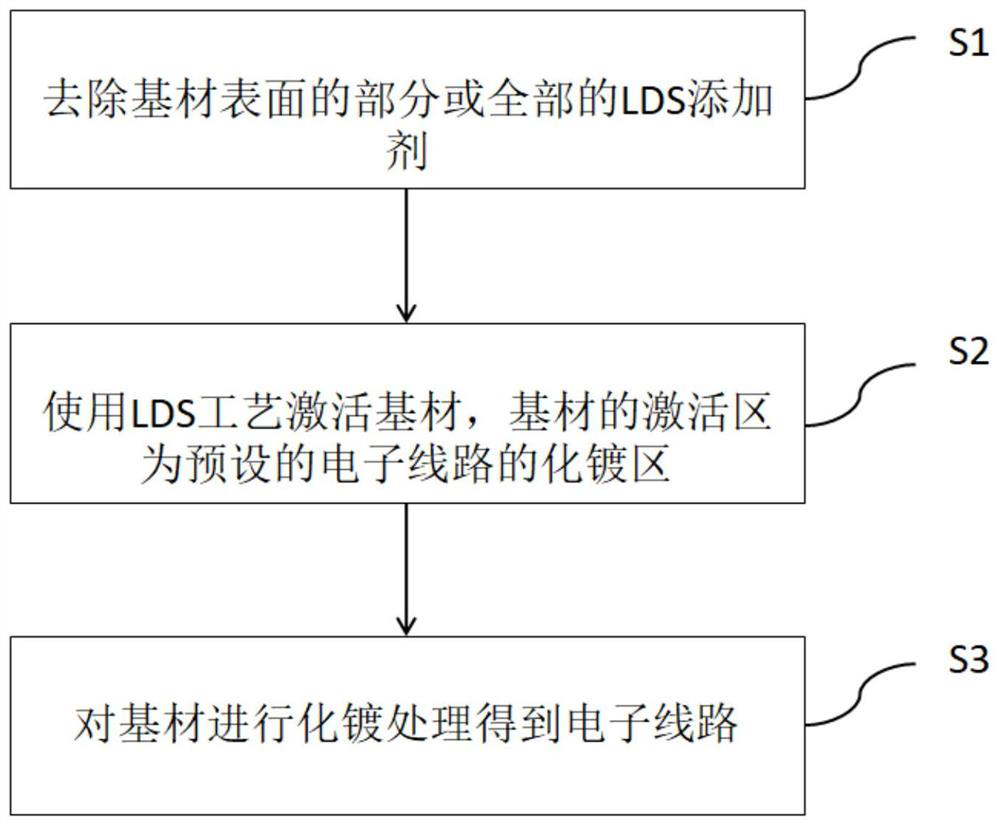

[0032] see figure 1 , a method for preparing an electronic circuit 2 on a substrate 1, comprising:

[0033] S1, removing part or all of the LDS additive on the surface of the substrate 1;

[0034] S2, using the LDS process to activate the substrate 1, the activation area of the substrate 1 is the preset electroless plating area of the electronic circuit 2;

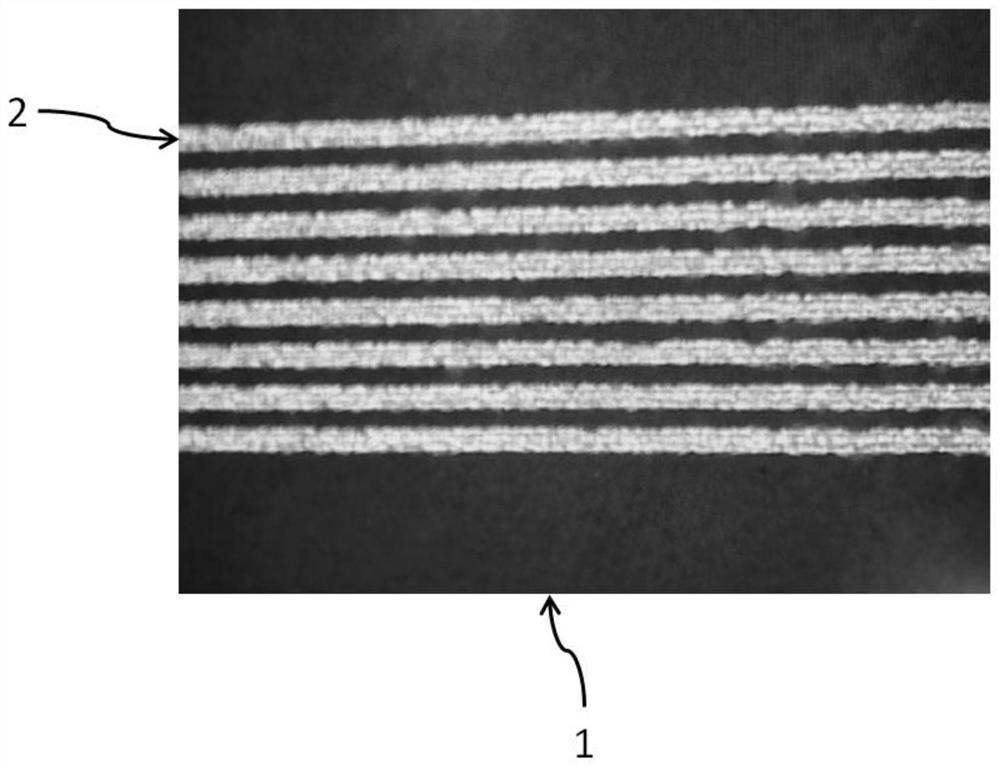

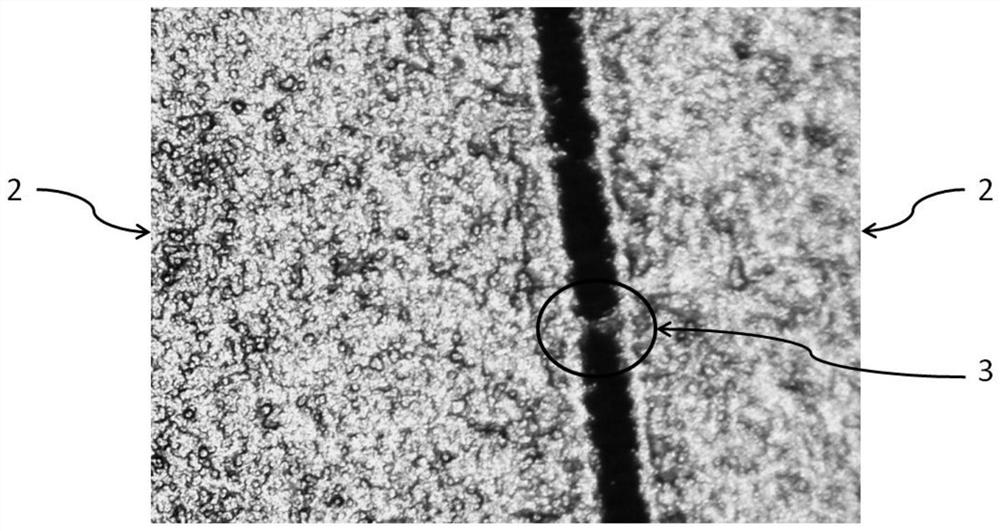

[0035] S3, performing electroless plating treatment on the substrate 1 to obtain the electronic circuit 2 . For the product structure prepared in this step, see figure 2 .

[0036] The substrate 1 in this embodiment can be a plastic material containing metal elements, and the metal elements usually exist in the form of compounds (LDS additives). The metal particles are based on the metal particles during the electroless plating, and a metal plating layer will be formed in the area irradiated by the laser (the preset electroless plating area of the electronic circuit 2 ) to form the electronic circuit 2 .

[003...

Embodiment 2

[0048] see Figure 8 , a method for preparing an electronic circuit 2 on a substrate 1, comprising:

[0049] B1, injecting glass fiber into the base material 1, the direction of the glass fiber is consistent with the direction of the preset electronic circuit 2;

[0050] B2, removing part or all of the LDS additive on the surface of the substrate 1;

[0051] B3, using the LDS process to activate the substrate 1, the activation area of the substrate 1 is the preset electroless plating area of the electronic circuit 2;

[0052] B4, performing electroless plating treatment on the base material 1 to obtain the electronic circuit 2 . For the product structure prepared in this step, see figure 2 .

[0053] The substrate 1 in this embodiment can be a plastic material containing metal elements, and the metal elements usually exist in the form of compounds (LDS additives). The metal particles are based on the metal particles during the electroless plating, and a metal plating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com