A kind of super-capacity single battery injection and formation method

A technology of single battery and formation method, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of local capacity decay, poor contact of pole groups, and large number of internal parallel pole groups, etc. The uniformity, the inhibition of loose contact and the effect of saving the injection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0050] 1. Preparation of positive and negative electrode sheets

[0051] Preparation of positive and negative electrode sheets for lithium ion batteries, the specific manufacturing method is currently known in the technical field, and will not be described here;

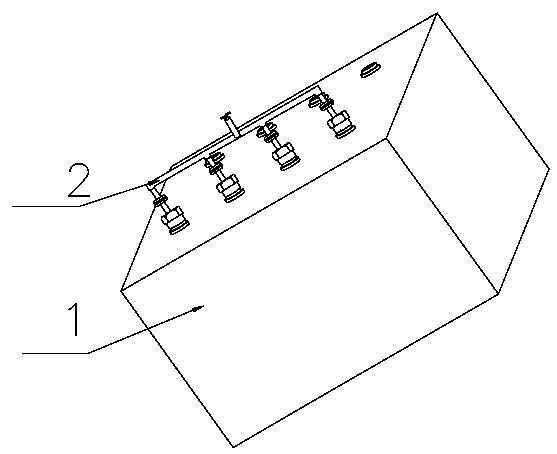

[0052] 2. Battery molding

[0053] The positive electrode sheets, separators, and negative electrode sheets made above are assembled into a certain number of pole groups by lamination or winding. After the pole groups are vacuum-dried, the pole groups are connected to one or more confluences through internal parallel connection. The structure is connected with the positive and negative poles to realize the function of exporting the current to the outside, and complete the battery assembly, the shell and the battery cover welding;

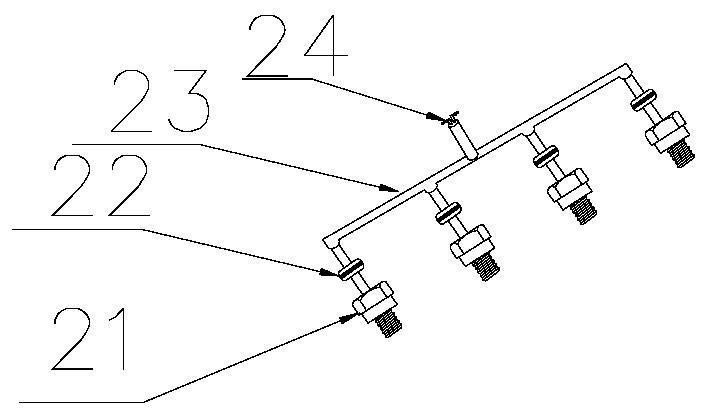

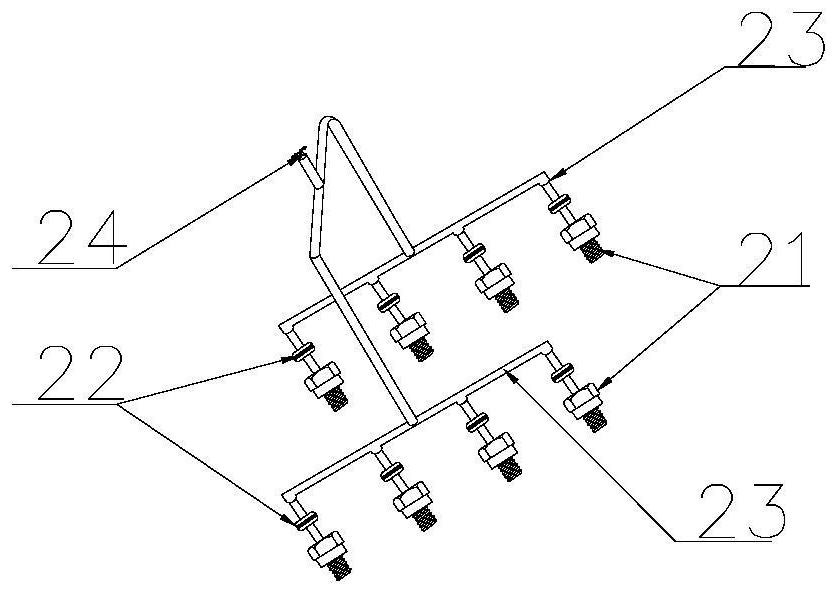

[0054] 3. Tooling installation

[0055] Under the environmental condition of dew point temperature of -30℃~-50℃, connect the multi-parallel comb-shaped liquid injection and sealing tool ...

Embodiment 1

[0077] Taking the 500Ah lithium iron phosphate system ultra-large single battery as an example, the battery preparation, liquid injection and chemical formation are carried out by referring to the following steps.

[0078] Step 1: Preparation of positive and negative electrode sheets

[0079] Prepare the positive and negative electrode sheets of the ultra-large-capacity lithium-ion single battery according to the existing known methods;

[0080] Step 2: Battery Molding

[0081] By means of lamination, the positive electrode and the negative electrode are separated by a diaphragm, and assembled into 10 50Ah small-capacity electrode groups to realize the electrode composition type; for 5 groups. The positive pole of each group is connected to the bottom of a positive pole, and the negative pole of each pole group is connected to the bottom of a negative pole. The super-capacity single battery contains a total of five positive poles and five negative poles to realize the functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com