A framing camera photocathode based on inorganic perovskite and its preparation method

A framing camera, photocathode technology, applied in the manufacture of light-emitting cathodes, secondary and light-emitting cathodes, main electrodes of discharge tubes, etc., to achieve excellent detection efficiency, simple steps, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

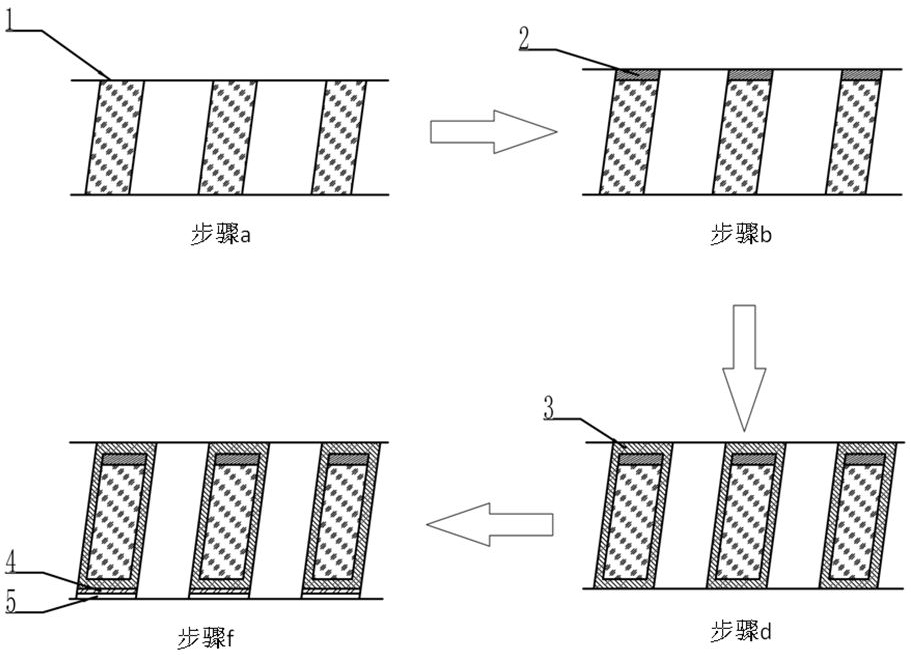

[0032] Such as figure 2 Shown, the preparation method of the framing camera photocathode based on inorganic perovskite of the present invention comprises the following steps:

[0033] 1. Provide a piece of MCP1, use alcohol to ultrasonically clean the MCP1 and then dry it;

[0034] 2. Cover the upper surface of MCP1 with a mask, and use the coating method of magnetron sputtering or atomic layer deposition to plate metal microstrip 2 on the upper surface of MCP1;

[0035] 3. Configure CsPbI 3 Precursor solution;

[0036] 4. Put the MCP1 obtained in step b into CsPbI 3 Precursor solution is heated until a layer of CsPbI is formed on the upper surface of the metal microstrip 2 and the inner wall of the microchannel of MCP1 3 film3;

[0037] 5. Convert the MCP1 obtained in step d from CsPbI 3 Take it out from the precursor solution, put it into an oven to heat and dry;

[0038] 6. Using the coating method of magnetron sputtering or atomic layer deposition, the lower surfac...

Embodiment 1

[0044]The CsPbI of the framing camera photocathode based on the inorganic perovskite of the present embodiment 3 Thin film 3 has a thickness of 50 nm.

[0045] The preparation process of the framing camera photocathode based on inorganic perovskite in this embodiment is as follows:

[0046] 1. Provide a piece of MCP1, use alcohol to ultrasonically clean the MCP1 and then dry it; the aperture of the microchannel is 3 μm, the thickness of the MCP1 is 100 μm, and the radial direction of the microchannel deviates from the surface normal of the MCP1 by 3°;

[0047] 2. Cover the upper surface of MCP1 with a mask, and use the coating method of magnetron sputtering or atomic layer deposition to plate metal microstrips 2 on the upper surface of MCP1; the number of metal microstrips 2 is 1, and the number of metal microstrips 2 The thickness of the copper layer is 500nm;

[0048] 3. Configure CsPbI 3 Precursor solution; its polar organic solvent is DMF;

[0049] 4. Put the MCP1 obta...

Embodiment 2

[0053] The CsPbI of the framing camera photocathode based on the inorganic perovskite of the present embodiment 3 Thin film 3 has a thickness of 150 nm.

[0054] The preparation process of the framing camera photocathode based on inorganic perovskite in this embodiment is as follows:

[0055] 1. Provide a piece of MCP1, use alcohol to ultrasonically clean the MCP1 and then dry it; the aperture of the microchannel is 5 μm, the thickness of the MCP1 is 500 μm, and the radial direction of the microchannel deviates from the surface normal of the MCP1 by 4°;

[0056] 2. Cover the upper surface of MCP1 with a mask, and use the coating method of magnetron sputtering or atomic layer deposition to plate metal microstrips 2 on the upper surface of MCP1; the number of metal microstrips 2 is 4, and the number of metal microstrips 2 The thickness of the copper layer is 1000nm;

[0057] 3. Configure CsPbI 3 Precursor solution; its polar organic solvent is GBL;

[0058] 4. Put the MCP1 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com