Stainless steel slag treatment device and treatment method thereof

A stainless steel slag and processing device technology, applied in the field of metallurgical slag processing, can solve the health and personal safety hazards of workers, accelerate the corrosion of steel structure workshops, and diffuse steam, so as to benefit workers' labor health and avoid exhaust pipes Leakage, the effect of improving the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

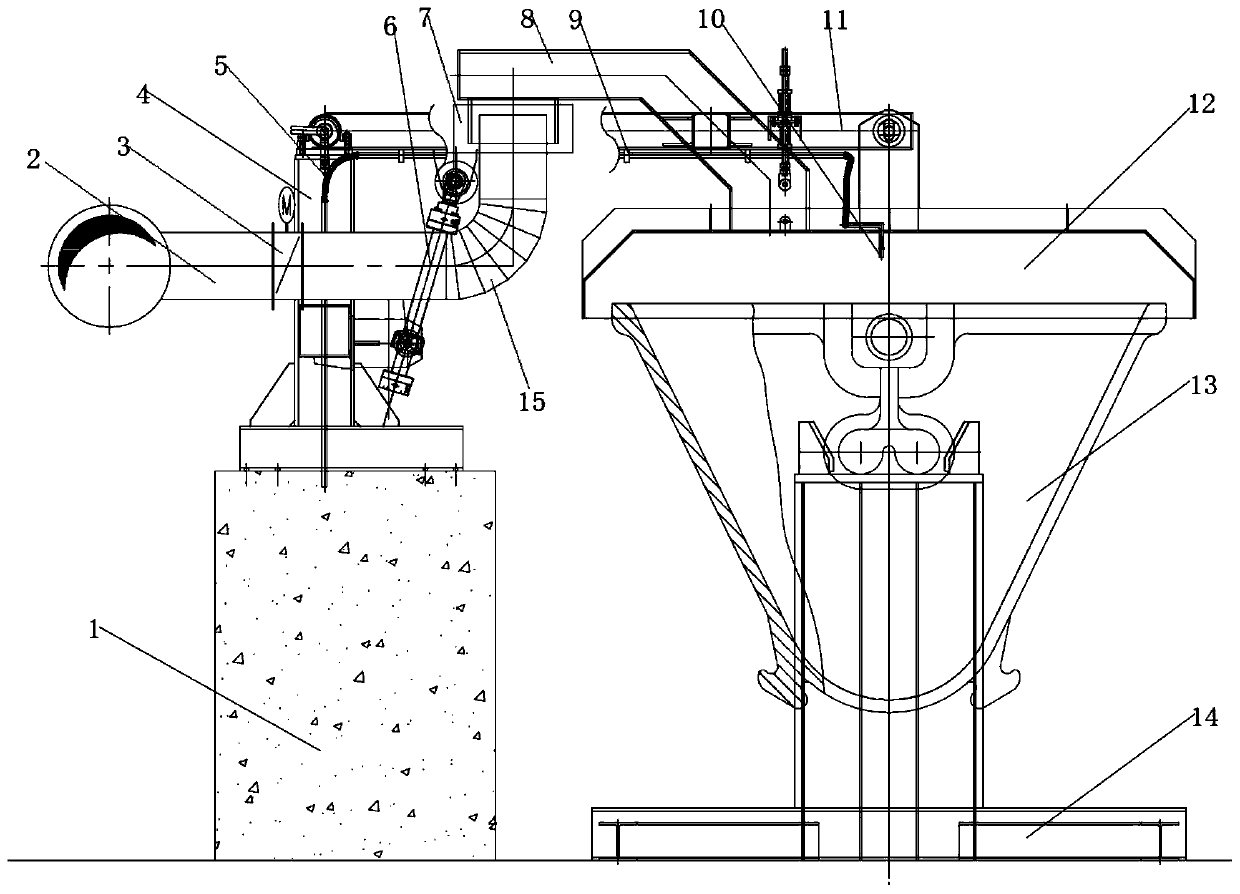

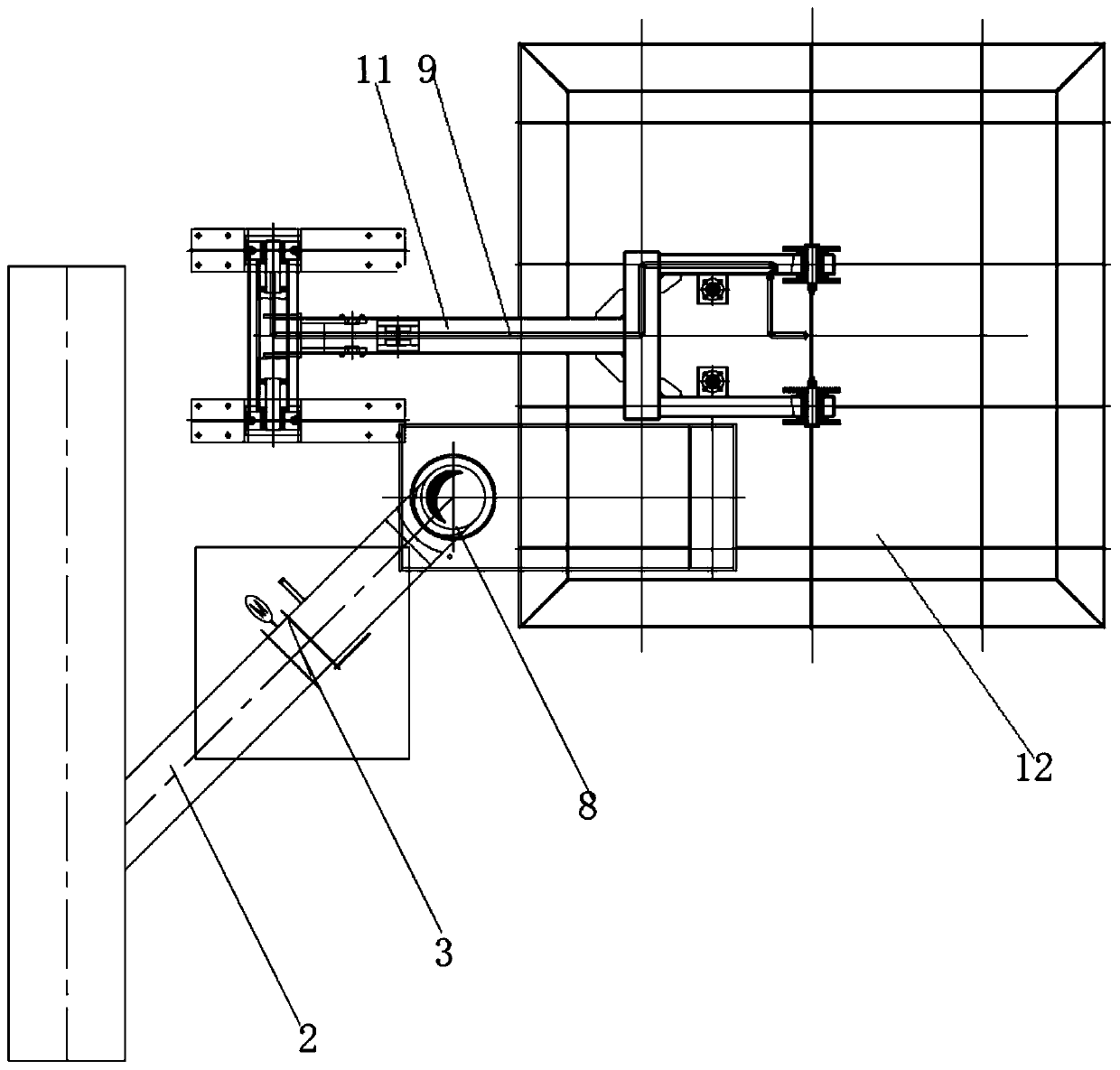

[0029] Such as figure 1 and figure 2 As shown, a stainless steel slag processing device includes a slag tank 13 arranged on a slag tank support 14, a fixed frame 4 set on the foundation 1 (through anchor bolts), a dust removal cover 12 with a dust removal port, and a dust removal cover 12 at one end. The swing arm 11 that is hinged with the fixed frame 4 and the other end is fixedly connected to the outside of the dust removal cover 12 (by welding), is used to drive the swing arm 11 to swing around the hinge point to realize the dust removal cover 12 to cover and open the hydraulic cylinder of the slag tank 13, and is arranged on The water supply pipe 9 on the fixed frame 4 and the swing arm 11, the water supply control valve provided on the water supply pipe 9, the atomizing nozzle 10 located at the end of the water supply pipe 9 and located inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com