Colored packaging adhesive film with long-term fadeless performance and preparing method thereof

A packaging film and color technology, applied in the direction of film/sheet without carrier, adhesive, photovoltaic power generation, etc., can solve the problems that affect the battery sheet, durability needs to be improved, and affect the power generation efficiency, so as to achieve high power generation efficiency and color Good staying power, bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

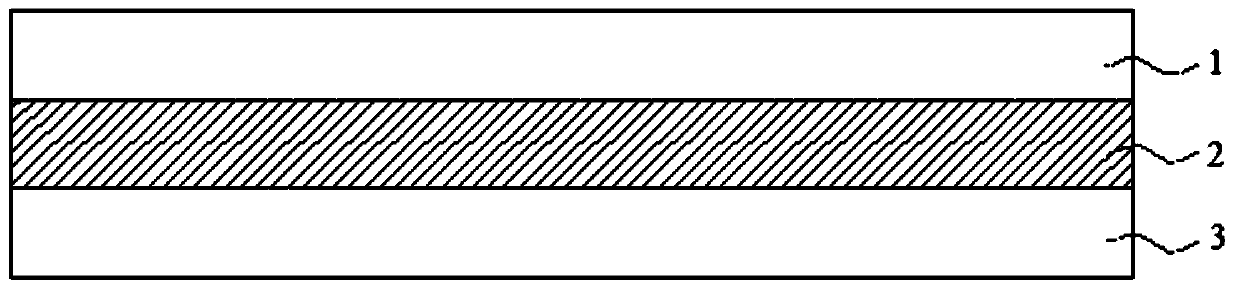

[0058] The long-lasting and non-fading color encapsulating adhesive film of this embodiment includes a transparent layer 1 and a colored layer 2 arranged in sequence from top to bottom. The thicknesses of the transparent layer 1 and the colored layer 2 are 100 μm and 400 μm respectively, wherein the transparent layer and the colored layer The specific composition of the layer is as follows:

[0059] In parts by weight, the color layer comprises the following components:

[0060]

[0061] In parts by weight, the transparent layer comprises the following components:

[0062]

[0063]

[0064] The preparation method of the colored packaging adhesive film of the present embodiment comprises the following steps:

[0065] Step (1), the raw materials of the colored film layer and the transparent film layer are mixed evenly, and then plasticized by a co-extrusion casting machine and extruded and cast by a T-shaped die to form a film, and the processing temperature is set at ...

Embodiment 2

[0068] The long-lasting and color-fast color encapsulating adhesive film of this embodiment includes a transparent layer 1 and a colored layer 2 arranged in sequence from top to bottom. The thicknesses of the transparent layer 1 and the colored layer 2 are 50 μm and 450 μm respectively, wherein the transparent layer and the colored layer The specific composition of the layer is as follows:

[0069] In parts by weight, the color layer comprises the following components:

[0070]

[0071] In parts by weight, the transparent layer comprises the following components:

[0072]

[0073] The preparation method of the colored packaging adhesive film of the present embodiment comprises the following steps:

[0074] Step (1), the raw materials of the colored film layer and the transparent film layer are mixed evenly, and then plasticized by a co-extrusion casting machine and extruded and cast by a T-shaped die to form a film, and the processing temperature is set at 70°C;

[007...

Embodiment 3

[0077] The permanent non-fading color encapsulating adhesive film of this embodiment includes a transparent layer 1, a colored layer 2 and a transparent layer 3 arranged in sequence from top to bottom, and the thicknesses of the transparent layer 1, the colored layer 2 and the transparent layer 3 are respectively 50 μm, 400μm, 50μm, where the specific composition of the transparent layer and the color layer is as follows:

[0078] In parts by weight, the color layer comprises the following components:

[0079]

[0080] In parts by weight, the transparent layer comprises the following components:

[0081]

[0082] The preparation method of the colored packaging adhesive film of the present embodiment comprises the following steps:

[0083] Step (1), the raw materials of the colored film layer and the transparent film layer are mixed evenly, and then plasticized by a co-extrusion casting machine and extruded and cast by a T-shaped die to form a film, and the processing temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com